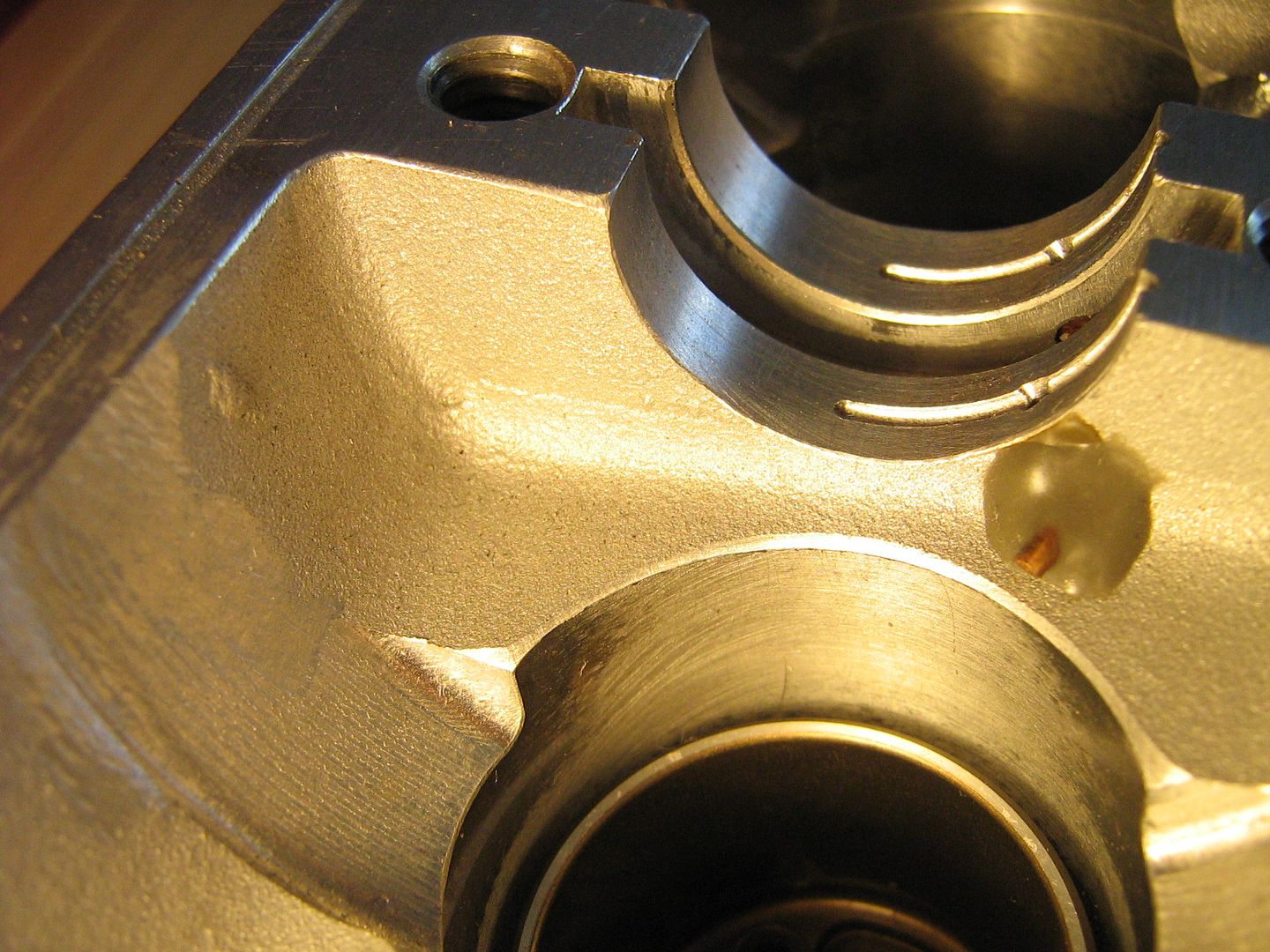

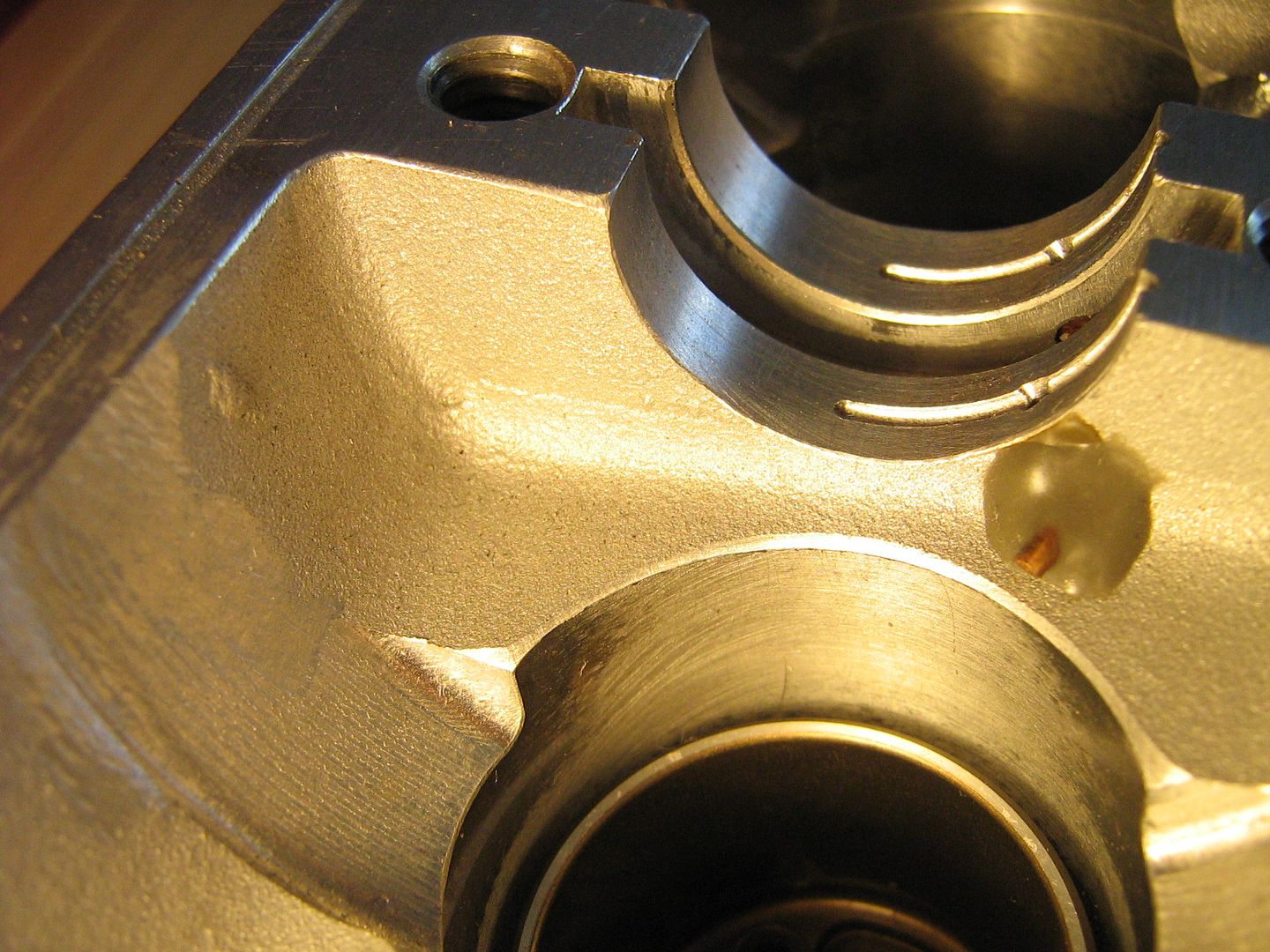

Here's an inside look at a V10 F1 head.

Pretty interesting.

CLIFF NOTES - if you're too lazy to read the whole thing, after all it is over a paragraph long, then you don't deserve to learn anything about it.

One thing I thought was real cool was getting to actually see the pneumatic valve actuators both inside & out.

F1 head cutaway

WOW..

Very cool, thanks for sharing.

That was an awesome read, thank you for posting!

Damn that thing is awesome. I'd have read the words but my head would literally explode like and F1 engine at 20000rpm.

Is that, no it can't be, JB WELD?

I thought that was a nice addition. In fact, I'm working on my own camshaft squirters using the same idea right now!

I noticed that too. i was surprised at how many corners seemed to be cut or make do solutions were used. I think of F1 as cutting edge, but then again they are very low volume engines so I guess stuff like that is the best solution.

I wonder if this is the same "Brian G." who made a carbon fiber tea spoon which slowly morphed into casting his own vw cylinder heads and building his own machine shop.

I sure appreciate his detail, and I'm glad some people choose to share their brains on the internet. It is obviously a lot of work to put that post together.

JB Weld is a two-part epoxy, so call it that if you prefer. What kind of cutting edge stuff do you want to see? It's the right solution for something like that.

IDK, its just kinda scary to think the same thing holding my $400 car's gas tank together is holding bits inside a F1 engine. Something I can buy at walmart.

daytonaer wrote:

I wonder if this is the same "Brian G." who made a carbon fiber tea spoon which slowly morphed into casting his own vw cylinder heads and building his own machine shop.

I sure appreciate his detail, and I'm glad some people choose to share their brains on the internet. It is obviously a lot of work to put that post together.

It is - Brian Garvey...pretty awesome guy

Kenny_McCormic wrote:

IDK, its just kinda scary to think the same thing holding my $400 car's gas tank together is holding bits inside a F1 engine. Something I can buy at walmart.

That means that you're using F1 technology on your $400 car! How cool is that?

I'm sure the stuff in the F1 engine costs far more, though.

I thought this was going to be about someone cutting into Vettel's head...

Shaun

HalfDork

9/9/13 12:14 p.m.

Those heads are fantastic pieces of engineering, and the write up was concise and knowledgeable. Great post, thanks for putting that up.

So similar to the 4A-GE...

Well, they do have four valves per cylinder and spark plugs. I'm not seeing much else.

Shaun

HalfDork

9/9/13 1:10 p.m.

think about the splayed valvestems and necessarily complex cam geometry for a sec. hollow cams that spin at 15k and deliver oil at that. really trying to understand what it took to encase the combustion chamber in water and get that out of a single casting made my head hurt. At best one could say they are very very deceptively simple pieces. The duty cycle in insane, the development cycle time constraint unreasonable to the extreme, failure margin vs weight decisions are far from simple as it is a major component part of an assembly that is a stressed member, and on and on and on. Gnarly.

IF you have in-cam oiling.... (Toyota 4AGE) you can drill the lobes to oil each bucket individually... no JB Weld required

the advantage this system has... as rpms increase... more oil is sprayed on the bucket... where as if you depend on oiling through the cam... as rpm increase... so does centripetal force... throwing more of the oil other places..... and NOT on the buckets as much