Thread from 2017:

So after this past weekend fun of 6 trips to the store for bits, taps, and then making sure they were the right ones, I'm looking for a drill bit set. A **good** drill bit set, as I type this I just got done destroying a brand new 3/8ths bit trying to drill a piece of black iron pipe. I got 1.5 holes, and I even drilled 1/8"pilots. When using a drill press, it was no problem, but my hand drill put up a fight. These were also different bit sets, so it could just be crappy bits on my part. I'd actually prefer something that goes by number, if at all possible. Yes I can print out a conversion chart (#3 bit= 7/32" sort of thing) but if they were numbered in the set it would be easier for most of my applications. I'd like one full set with everything under 1", but I wouldn't be against buying standard and metric sets to fill in all the blanks. From what I can tell, most usage will be in aluminum, steel, brass, or copper, but there will be some wood work that I won't need paddle bits for I'm sure. So. Is there a brand, chemical composition, or anything to look out for? Are drill bits just a disposable commodity best purchased in bulk? I currently only have hand drills, but a drill press is extremely high on my list of tools to purchase, possibly as early as tax time. I'm not sure if that would make a difference, but I'm throwing it out there.

I bought a titanium nitride set from Sam's years ago, complete index, numbered, lettered, fractional. I have destroyed a few, but they are good quality. Much better quality than the TiN from HF. My Drill Doctor has paid for itself in gasoline and time running to the store for more drill bits.

Buy them from anywhere BUT hf. Whenever you destroy a bit, buy a half dozen of that size. You'll find that you really don't use that many different sizes and you'll settle on the common ones.

Bits are disposable and when you dull one, make sure it goes in the trash or you'll be annoyed the next time you try to use it.

Get a couple of good uni-bits, they are the bomb!

are cobalt bits any good?

Number bits are not the same size as fractional bits and neither are the same size as letter bits.

A machinist index like this with letter, number and fractional up to 0.50" bits is just over 300 for good quality. Hertel is available through MSC.

That gets you nowhere near your 1" though. I would suggest buying piecemeal in larger sizes.

EvanB

UltimaDork

1/19/17 8:05 a.m.

Teh E36 M3 wrote:

are cobalt bits any good?

Depends on the quality. Cobalt is more heat resistant so it is good for higher speed and production work.

A good quality HSS bit will be better than a cheap Cobalt.

For quality bits, I usually buy Irwin. That is what is in the index beside the mill. They should last me forever.

For jobber bits for work or running in the hand drill, that just need to make a quick hole, I usually order 10 packs from CR Laurence. They are better quality than the crap Lowes and HD sell and on par with the bulk bits at most hardware stores, but cheaper. When they get dull, I pitch them. As stated above, there are only a half dozen sizes that are used regularly and I keep a pack or two of each on hand.

youngfg

New Reader

1/19/17 9:58 a.m.

Get a USA made set.

Also learn how to sharpen drill bits, it's easy, look it up on youtube, then when you dull a bit you can be good as new in a few seconds.

I've not come across a need for lettered bits, I honestly didn't know there was such a thing.

I bought the same black oxide dewalt set my buddy had today, but a proper index is now in the cards.

I was surprised how few options there were without the damn quick change end that ensures you'll never drill a straight hole.

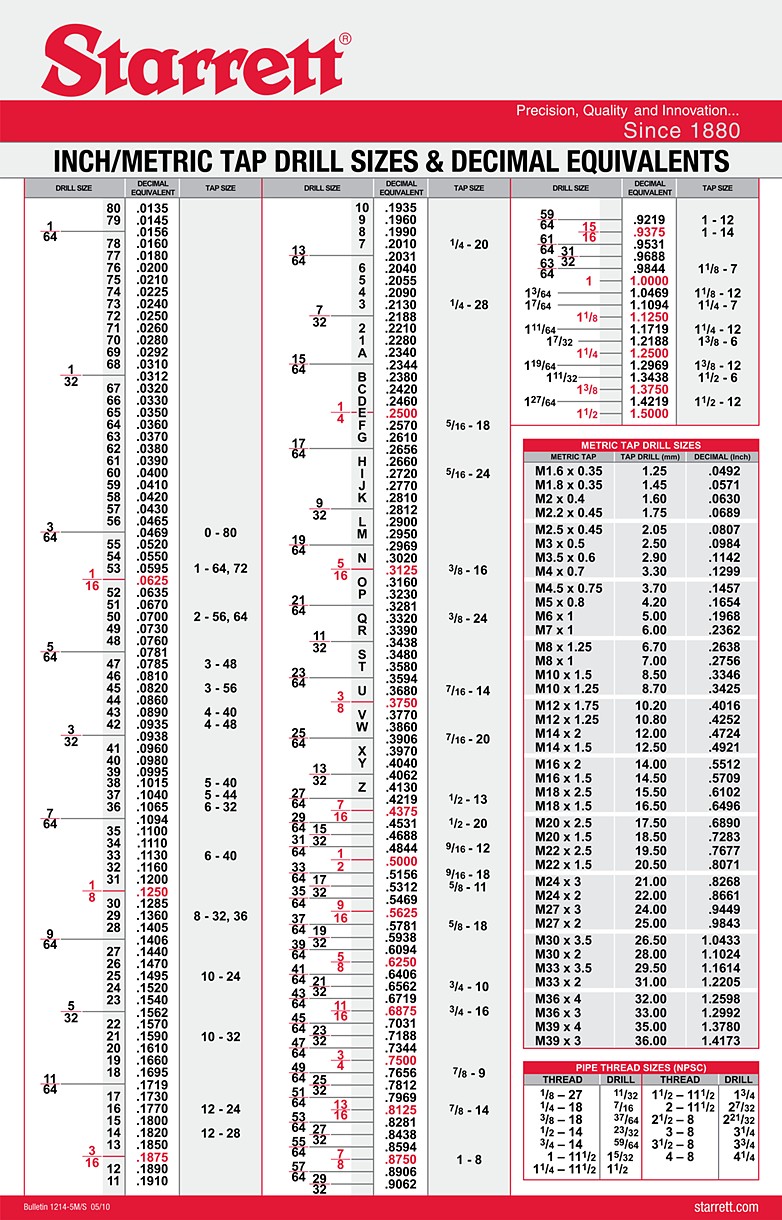

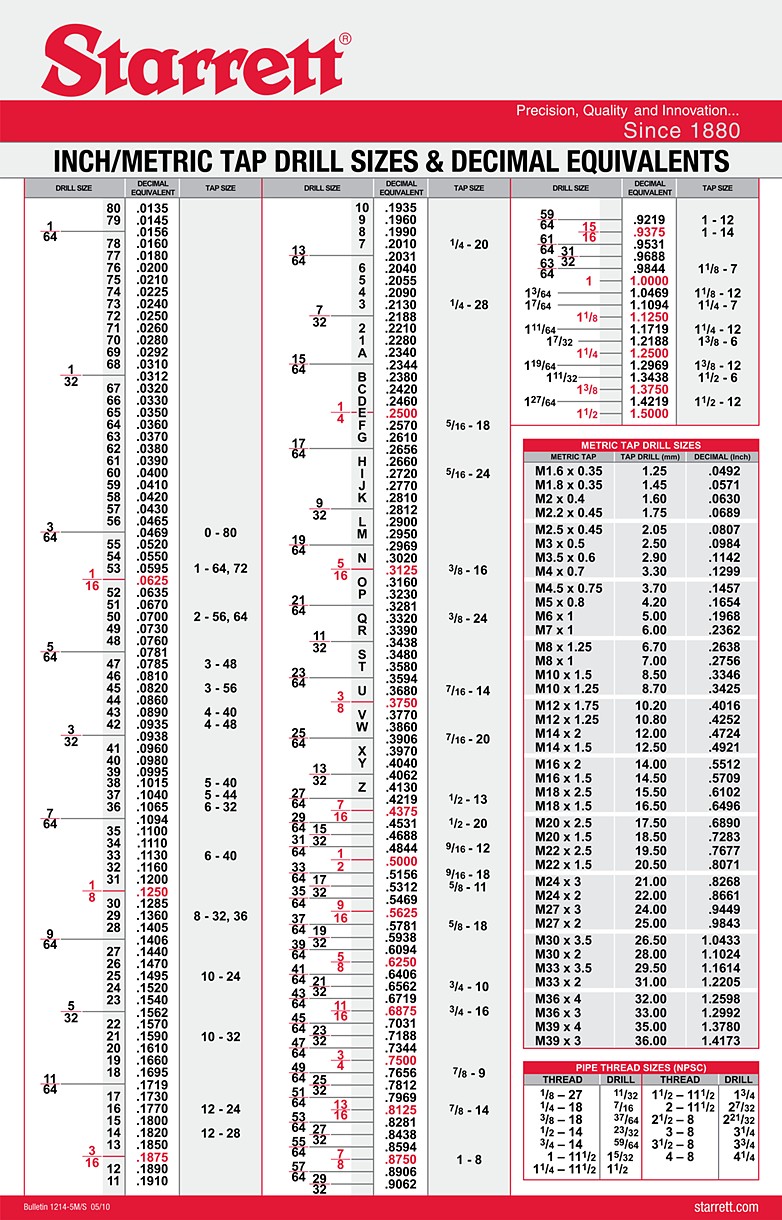

Here is a pretty standard drill/tap chart. You can see how fractional, number and letter bits are never the same size and how you technically will require a set of each for all tapping operations. It is a mess and one of the reasons why I prefer metric for most things. Yes you can fudge one way or another and get by. I tend to go with the fractional bit one size under the required letter bit for most tapping operations down to 5/16" if I don't have access to my proper drill index. Once you start tapping 1/4" and under you have to have number bits.

I find that an index like this is too much work for more casual users. When I get other people in my little machine shop the bits are never put back into their proper places. Organization is critical, you can easily destroy a project with a misplaced bit.

For a smaller setup I would recommend one of these in SAE and metric

and one of these up to 1/2"

Again, piecemeal the larger sizes as needed.

KyAllroad wrote:

Bits are disposable and when you dull one, make sure it goes in the trash or you'll be annoyed the next time you try to use it.

Pretty sure any good quality bit can be restored to like-new condition with proper sharpening.

1988RedT2 wrote:

KyAllroad wrote:

Bits are disposable and when you dull one, make sure it goes in the trash or you'll be annoyed the next time you try to use it.

Pretty sure any good quality bit can be restored to like-new condition with proper sharpening.

When I took a "machine shop" class years ago; just because I wanted to; one of the first things they teach you is how to sharpen a drill bit. They give you a bit somewhere between 1/2 inch and 1 inch and after the instructor explains how to do it and shows you how to do it you have to sharpen one and then use it to drill a hole on a drill press.

You learn fast how to do it right otherwise it's hard to drill a hole that meets the requirements of the class! It's been well over 20 years since and the only time I have to buy a drill bit is in the very small sizes like under 1/8 inch or if I break one, but that doesn't happen often.

jimbbski wrote:

1988RedT2 wrote:

KyAllroad wrote:

Bits are disposable and when you dull one, make sure it goes in the trash or you'll be annoyed the next time you try to use it.

Pretty sure any good quality bit can be restored to like-new condition with proper sharpening.

When I took a "machine shop" class years ago; just because I wanted to; one of the first things they teach you is how to sharpen a drill bit. They give you a bit somewhere between 1/2 inch and 1 inch and after the instructor explains how to do it and shows you how to do it you have to sharpen one and then use it to drill a hole on a drill press.

You learn fast how to do it right otherwise it's hard to drill a hole that meets the requirements of the class! It's been well over 20 years since and the only time I have to buy a drill bit is in the very small sizes like under 1/8 inch or if I break one, but that doesn't happen often.

Unless they are split point, which are nearly impossible to hand sharpen.

Non-split points should always use a punch to start. They will last much better.

Hal

UltraDork

1/19/17 3:56 p.m.

Dr. Hess wrote: My Drill Doctor has paid for itself in gasoline and time running to the store for more drill bits.

Love my Drill Doctor! My father taught me how to sharpen a drill bit when I was ~12 years old. And being a shop teacher, I had to do many over the years. But it was so much easier with the DD that I went through all 6 of my indexes in one afternoon.

RevRico wrote:

I've not come across a need for lettered bits, I honestly didn't know there was such a thing.

If you want/need proper tap and clearance holes for SAE hardware you need letter bits, and number bits for the small numbered threads.

A good bit, and the right bit, makes all the difference in the world.

So where can you buy a real index of sharpenable bits? Eastwood had one but they stopped selling it right before I bought it. None of my local hardware stores sell them. All I can get is the coated ones which I found out can't be sharpened.

Good how to on sharpening bits? ALL of mine are dull....

I sharpen by eye on a high speed belt sander.

Any welding shop worth a E36 M3 has good drills.

Fastenall

Ace Hardware

Sears?

Irwin

pjbgravely wrote:

So where can you buy a real index of sharpenable bits? Eastwood had one but they stopped selling it right before I bought it. None of my local hardware stores sell them. All I can get is the coated ones which I found out can't be sharpened.

Coated bits can be re-sharped but the coating will not be as effective as the cutting edge will only have the coating on the upper side of the edge. If the bit is made of "good" HHS then I don't see any real downside unless your drilling very hard steel. For that I usually get a small carbide tipped drill or a solid carbide drill to make a pilot hole.

tb

HalfDork

1/23/17 10:41 a.m.

I would really like to get a drill sharpener device since my hands are no longer steady enough to do it manually. I have only the most modest of work benches and am a small time hobbyist at best so this would only be for occasional use, mostly on sheet metal and aluminum stock.

Is the Drill Doctor the preferred method or should I check out another brand? Can I get away with the $50 model or should I go straight to the $150 version? Are there any must have accessories that I do not know about?

TIA

pjbgravely wrote:

So where can you buy a real index of sharpenable bits?

What I use Hertel USA made

smaller set

This would probably be fine for someone less machine shop oriented Import black oxide

Personally, I get into too many situations where low quality bits and taps can cost me and my customers too much money. I get quality high speed steel stuff. When I do break stuff I replace it at our local machine tool supply.

Precision Twist Drill has done me well over the years, have to find a place that sells Sandvik Coromant cutting tooling however to get it.

In reply to pjbgravely:

You can sharpen the titanium nitride coated ones, it's just a gold colored high speed bit at that point though, and usually inferior to a cheaper plain bit unless you get spendy. It's my understanding that the coated bits are kinda a gimmick for home/manual use anyway, they make more sense in a CNC machine where you've got coolant and precise speed/feed control to prevent accidentally burning the coating off, stick to HSS (good) or Cobalt (better).

It does seem the smaller basic steel indexes have mostly gone away and you have to buy the full 115 piece (1-60 A-Z 1/16-1/2) sets if you want a steel box to keep them in without spending big money. The HF sets usually aren't bad for the money, at least good enough to use and eventually swap the more commonly used sizes out for nice USA bits from the machine shop supply store, that's the route I went.