She suggested that in some cases she changed the tests to passing grades because she thought it was “stupid” that the Navy required the tests to be conducted at negative-100 degrees Fahrenheit (negative-73.3 degrees Celsius).

I get it. I don't agree, but I get it.

In reply to Mr_Asa :

There's a whole science dedicated to HALT "highly accelerated life testing" and temperature is a very common variable used to quickly estimate what is likely to happen in the future.

In this case, I suspect the test called for much lower temperatures than the sub will ever see operationally to make the metal more brittle during pressure cycle testing.

Essentially, material scientists and statisticians collaborate on the construction of models which will predict something like 95 percent chance that 95 percent (95/95 C&R) of subs can withstand 10,000 pressure cycles in the real world if the parts fail at 100+ cycles in the lab at -100 F.

She's a metallugist which is just one of many skills required to achieve good confidence.

Sounds like something that could lead to future failure and reminds me of the passage from Yeager's bio about the factory worker who got a few pilots killed by assuming the specs were false...

"As a young USAF test pilot, he was asked to fly the then new F-86 Saber to determine why several had unexpectedly crashed. Several Sabers had last been seen flying at low altitude, inverted before crashing with no survivors. Yeager mounted his Saber to determine the cause of these tragic accidents. I short order, he had his answer. Once inverted, the ailerons on his Saber would lock up and become immovable. Once the aircraft was rolled right-side-up, he regained aileron control. Upon detailed inspection after the flight, it was determined that a crucial bolt in the aileron assembly process had been installed incorrectly, leading to the jamming of the controls when inverted. When the manufacturing process was inspected at North American Aviation, it was determined that a factory worker was installing the bolts upside-down, because they were installed that way on every other NA aircraft he had built in his lengthy career at NA (P-51, T-6, etc.)."

In reply to RX Reven' :

Y'know, I've followed this story as it developed and pointed that snippet out on just about every social media platform out there and this is the first time anyone has actually offered an actual explanation.

In reply to Mr_Asa :

The other thing to note is the part that mentioned "in SOME cases".

This one seems to be commons sense to the lay person, so it's easy to put in the news, and then question the Navy. With the correct answer that RX Reven' posts.

What they have not also posted is what other specifications were overlooked to falsify? If that was the only thing, it would be the one item that was overlooked. But it was just some of it.

BTW, we have a test that a normal person would think is insane, too- run and engine at full load, at full operating temp, and then suddenly put in -40F coolant to shock cool the engine. Of course that seems to be an absurd test. But it's the test that detects something specific, since that very specific test was designed. (I can't remember what it's the test for).

RX Reven' said:In reply to Mr_Asa :

There's a whole science dedicated to HALT "highly accelerated life testing" and temperature is a very common variable used to quickly estimate what is likely to happen in the future.

In this case, I suspect the test called for much lower temperatures than the sub will ever see operationally to make the metal more brittle during pressure cycle testing.

Essentially, material scientists and statisticians collaborate on the construction of models which will predict something like 95 percent chance that 95 percent (95/95 C&R) of subs can withstand 10,000 pressure cycles in the real world if the parts fail at 100+ cycles in the lab at -100 F.

She's a metallugist which is just one of many skills required to achieve good confidence.

As a guy who done 30 years in testing (and almost that much time running HALT tests) - I'm not sure they were running these tests (HALT) on metal samples. I know they do run tensile tests at temperature and have a laundry list of metal specific tests they run - I'd be interested to see what tests they were running. It would not be surprising that the NAVY asked for a normal test to be run at -73C, seen it many times.

Kendall_Jones said:RX Reven' said:In reply to Mr_Asa :

There's a whole science dedicated to HALT "highly accelerated life testing" and temperature is a very common variable used to quickly estimate what is likely to happen in the future.

In this case, I suspect the test called for much lower temperatures than the sub will ever see operationally to make the metal more brittle during pressure cycle testing.

Essentially, material scientists and statisticians collaborate on the construction of models which will predict something like 95 percent chance that 95 percent (95/95 C&R) of subs can withstand 10,000 pressure cycles in the real world if the parts fail at 100+ cycles in the lab at -100 F.

She's a metallugist which is just one of many skills required to achieve good confidence.

As a guy who done 30 years in testing (and almost that much time running HALT tests) - I'm not sure they were running these tests (HALT) on metal samples. I know they do run tensile tests at temperature and have a laundry list of metal specific tests they run - I'd be interested to see what tests they were running. It would not be surprising that the NAVY asked for a normal test to be run at -73C, seen it many times.

Doesn't the Navy periodically perform operations under the polar icecap? I'd imagine -73C wouldn't be too far out of the ordinary in those conditions.

its probably about design margins - Its not simulating an environment but rather measuring properties of the steel under certain conditions.

This foundry probably made the steel for a navy contract and as part of the contract they have to supply paperwork / certs to the navy for each batch of steel. Probably none of those tests were in real world ocean numbers, probably pretty mundane (chemical content, rockwell hardness, tensile, etc) .

I suspect the navy said do this test, and then do it again at super cold temps. Metallurgist probably said "thats dumb".

Anyway, I would like to see the details rather than the clickbait ;)

06HHR (Forum Supporter) said:Doesn't the Navy periodically perform operations under the polar icecap? I'd imagine -73C wouldn't be too far out of the ordinary in those conditions.

I'm pretty sure the subs prefer to operate in liquid water.

Its apparently the Navy safety factor criteria to establish the toughness of the steel. When steel gets cold it is more susceptible to brittle fracture instead of deformation(stretching before rupturing). The lower the temperature that the steel can pass this test the more resistant it is to brittle fracture.

Toughness is a measure of how much resistance a steel has to fracturing.

I remember reading about the structural failure of a US submarine that happened back in the 60's. The nose cone suffered an annular brittle fracture. I think the sub was in trouble and deeper than its safety factor limited maximum depth.

The investigators estimated that the nose cone traveled inside the occupied submarine,from front to back, at the speed of sound in water.

"Velocity of sound in Water: 1450 m/s, 3240 miles/hour"

06HHR (Forum Supporter) said:Doesn't the Navy periodically perform operations under the polar icecap? I'd imagine -73C wouldn't be too far out of the ordinary in those conditions.

Remember the freezing temp of water is 0C, also as pressure increases water freezes at higher temps. Its a very small climb, but it happens.

The fact of the matter is she falsified a test document. I work in aerospace materials and the standards are pretty similar. It's stamp integrity and there is no room for interpretation. Your job is to follow the process. The companies job is to ensure they have a compliant process. Falsifying data is a no no. We are all trained on it annually and every year they tell you in no uncertain terms if you falsify information not only can you be fired, you can be fined and you can be jailed. If she felt so strongly the test was silly then she should have put in a change request or the company should have taken exception to the spec in the PO acceptance.

The other issue (the first being safety of the end product) is by skipping a process step the company has a financial advantage. In this case it probably is very small but if company a is cutting corners then company b and c doesn't have a fair shot at that business.

Mr_Asa said:06HHR (Forum Supporter) said:Doesn't the Navy periodically perform operations under the polar icecap? I'd imagine -73C wouldn't be too far out of the ordinary in those conditions.

Remember the freezing temp of water is 0C, also as pressure increases water freezes at higher temps. Its a very small climb, but it happens.

Freezing temp of fresh water is 0C. It's lower for salt water. Only a few degrees, but it matters.

If you saturate the water with salt, it doesn't freeze until something like -20C. Which is why we salt our roads :)

At -73C, it's all froze.

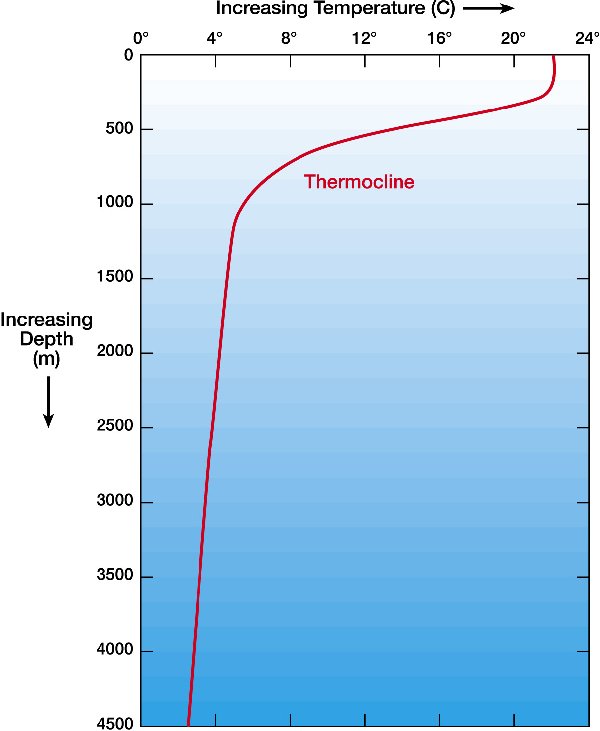

Deep ocean water makes up about 90% of the volume of the oceans. Deep ocean water has a very uniform temperature, around 0-3 °C, and a salinity of about 3.5% or as oceanographers state as 35 ppt (parts per thousand).

The thermocline varies in thickness from about 1,000 feet to 3,000 feet. Below this point water cools more slowly. At areas like the Mariana Trench (or the Marianas Trench; both spellings are commonly found) the water temperature ranges from 34-39 degrees F (1-4 degrees C).

https://www.peterainsworth.com/

But also- single point of failure like one person who can falsify test results is not good.

And, who cares if it is "stupid". They paid for a product with certain characteristics. If you can't provide it, don't lie about it. Sentence: too short, with what little information I have, and fine, too little. One sub destruction kills hundreds.

In reply to NY Nick :

The way I read it, she wasn't skipping the test, she was giving everything a passing grade even if it didn't pass.

"She suggested that in some cases she changed the tests to passing grades because she thought it was “stupid” that the Navy required the tests to be conducted at negative-100 degrees Fahrenheit (negative-73.3 degrees Celsius)."

As a pilot, I want it all. The nastiest, most abusive, extreme tests imaginable. Stuff that will never be encountered in normal flight. Because in abnormal flight, my life depends on it.

In reply to Keith Tanner :

I was actually thinking about once they surface, the water won't be at -73C, but the surface temps could be routinely -20 to -30 on the ice. Internet says today it was -30. True, it's not conditions that most subs will ever experience, but the Navy does like to operate in extreme conditions from time to time. https://www.defensenews.com/naval/2020/05/11/the-us-navy-returns-to-an-increasingly-militarized-arctic/

06HHR (Forum Supporter) said:In reply to Keith Tanner :

I was actually thinking about once they surface, the water won't be at -73C, but the surface temps could be routinely -20 to -30 on the ice. Internet says today it was -30. True, it's not conditions that most subs will ever experience, but the Navy does like to operate in extreme conditions from time to time. https://www.defensenews.com/naval/2020/05/11/the-us-navy-returns-to-an-increasingly-militarized-arctic/

I was thinking they might want to surface near Siberia where it can reach -40 to -60 on the surface.

When I worked on subs, repair and new construction, I was considered odd, 'cause I actually wanted the chance to go out on sea trials. Most folks didn't.

I always said that everyone that worked on each sub should have their name thrown in a lotto. If your name was selected, you Would HAVE to go out on sea trials.

Wonder if she would go?

In reply to Toyman! :

Same result skipping or improperly recording. If one of your guys signs off that a door is good to go does it matter if he didn't test it or he tested something and it was failing but he thought it didn't matter? Either way it is falsifying a document and that person has to go.

Appleseed said:As a pilot, I want it all. The nastiest, most abusive, extreme tests imaginable. Stuff that will never be encountered in normal flight. Because in abnormal flight, my life depends on it.

Ha! I'm a pilot too, same feelings.

You'll need to log in to post.