Piece of 5/8" rod running under the rear lip? That way it's still sort of a drop axle, but without having to make a drop axle.

Also - holla if you need any welding. I like this project.

Piece of 5/8" rod running under the rear lip? That way it's still sort of a drop axle, but without having to make a drop axle.

Also - holla if you need any welding. I like this project.

The stub axle idea will fail. Not enough metal to keep it stable. Bar off the lip looks good. Use U-bolts, plenty strong.

I think I just found the answer.

http://www.jalopyjournal.com/forum/showpost.php?p=4854567&postcount=182

I could buy a piece of steel from Home Depot and just bend it in a U shape. Looks like 2" wide by 3/16" thick steel. Then I can bolt it to the bottom of the wagon using the existing rear axle mounting holes. If I get any deflection I can always put a wood block between the axle and the body tub.

I want to keep the overall length as short as possible so I can still toss it in the trunk of my car, so mounting the axle off the rear of the tub won't really work unless I make some sort of quick release.

slefain wrote: I could buy a piece of steel from Home Depot and just bend it in a U shape. Looks like 2" wide by 3/16" thick steel. Then I can bolt it to the bottom of the wagon using the existing rear axle mounting holes. If I get any deflection I can always put a wood block between the axle and the body tub. I want to keep the overall length as short as possible so I can still toss it in the trunk of my car, so mounting the axle off the rear of the tub won't really work unless I make some sort of quick release.

i'm just going to go ahead and ask how the berkeley you're going to bend 3/16" plate?

if the rear wheels are removable from the axle, then hanging the axle from the back of the body only adds the thickness of the axle plus the attachment bracketry to the overall length.

AngryCorvair wrote:slefain wrote: I could buy a piece of steel from Home Depot and just bend it in a U shape. Looks like 2" wide by 3/16" thick steel. Then I can bolt it to the bottom of the wagon using the existing rear axle mounting holes. If I get any deflection I can always put a wood block between the axle and the body tub. I want to keep the overall length as short as possible so I can still toss it in the trunk of my car, so mounting the axle off the rear of the tub won't really work unless I make some sort of quick release.i'm just going to go ahead and ask how the berkeley you're going to bend 3/16" plate?

Big work bench, big vise, big pipe wrench, big cheater bar, big hammer. I may have the thickness wrong anyway. I haven't put my hands on the metal yet so I'm not sure. If I can't bend up something I'll just drill a hole through the sides, run a solid 5/8" threaded rod through the tub and be done.

I thought I took a picture this summer of a wagon but it was an old pedal car with a wagon handle. Everyone loved this car.

oh yeah......here it is - 2010 Japanese Classic Car Show.

When I get home I never ask the wife if she wants to see my pictures.........she just doesn't understand this stuff but I know you guys do.

slefain wrote:AngryCorvair wrote:Big work bench, big vise, big pipe wrench, big cheater bar, big hammer. I may have the thickness wrong anyway. I haven't put my hands on the metal yet so I'm not sure. If I can't bend up something I'll just drill a hole through the sides, run a solid 5/8" threaded rod through the tub and be done.slefain wrote: I could buy a piece of steel from Home Depot and just bend it in a U shape. Looks like 2" wide by 3/16" thick steel. Then I can bolt it to the bottom of the wagon using the existing rear axle mounting holes. If I get any deflection I can always put a wood block between the axle and the body tub. I want to keep the overall length as short as possible so I can still toss it in the trunk of my car, so mounting the axle off the rear of the tub won't really work unless I make some sort of quick release.i'm just going to go ahead and ask how the berkeley you're going to bend 3/16" plate?

2" w X 3/16" ain't bad at all to bend w/ oxy acetylene torch in a vise. It's gonna have some radius at the bend so account for that if doing a 90 or so. A piece of tubing or round bar clamped in the vise w/ the plate will give a nice uniform radius. Don't cut the plate to finish size, leave it long for leverage to bend. A larger crescent wrench on the end of plate provides enough leverage w/ the heat. Go slow w/ the bend (and use plenty of heat) or the radius might be larger than you want. BFH is usually not required. I actually prefer working w/ 3/16 than thinner stuff.

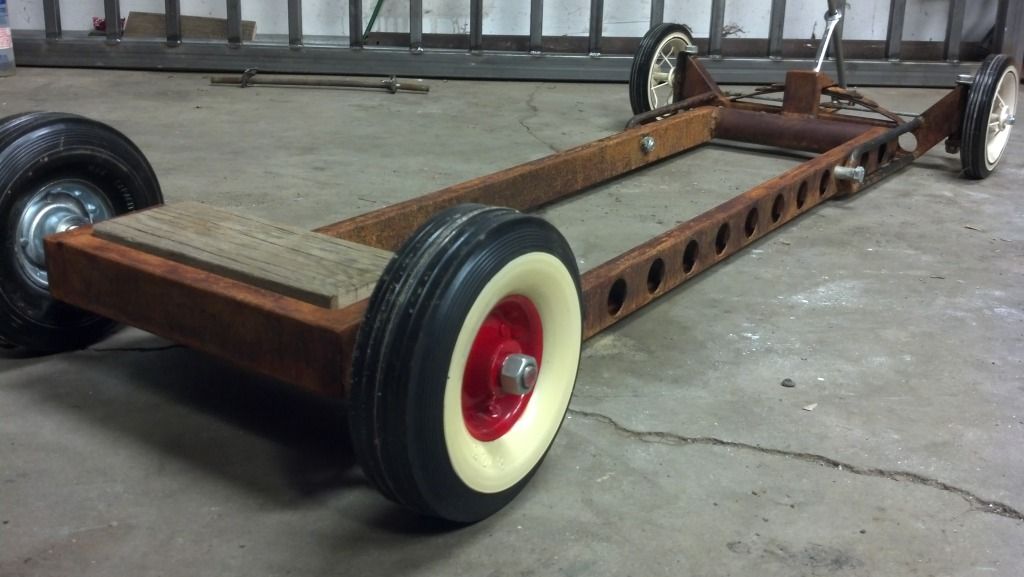

Progress:

Chassis is almost done, paint prep begins once I drill the holes for the rear axle.

I went Home Depot wandering and came up with two 6" x 6" 90-degree brackets that are pretty stout. I bolted them underneath the wagon along with a piece of U-channel I had sitting around.

The angle bracket is tensioned against the wagon lip and is pretty darn stout. Should really help control deflection. The bracket already had about 5-degrees of deflection built in so I used that to my advantage.

So things are moving right along. I was jazzed to get my pedestal grinder set up. I put a 10" wire wheel on one side which made cleaning up parts SO much easier, and the 10" grinding stone took all the sharp edges off the brackets in no time.

Now I need two 5" long 5/8" bolts with nuts and washers. I'm going to try for the stub axle idea. Worst case scenario I just buy a 2' long piece of threaded 5/8" rod and run a solid axle all the way across. I'm pretty sure the stub idea is going to work though, at least for my weight requirements.

Woohoo! Fab work is almost done!

This thing is big, I fit in it!

And yet it still fits in the trunk of a '75 Plymouth Duster.

I climbed in it. No problem carrying me and still rolling. And the rear axle is plenty stiff. In fact, the only movement in the rear wheels is from the cheap HF bearings.

This weekend I may start on paint prep. It needs a good washing before I prime it. I think it will get painted red since my son loves firetrucks.

I asked my wife if I could toss the front wheels in the dishwasher. Yeah, she may bring me home non-running project cars but I think I crossed the line with that question.

I'm taking notes. Looks pretty cool. My wife just quit her fire marshal job. Maybe I'll stumble across some stickers?

You guys will love this. I decided to go ahead and see what my son thought of the wagon. Remember, he's only a tad over 2 years old. I pulled it out of the garage and told him it was his. He smiled and said "race car, daddy, race car!" I pulled him around the driveway a few laps and then I figured it was maiden voyage time. We climbed in the wagon and rode it down the driveway. I'm not sure who was happier, him or me. Then it was time for his first solo run down part of the driveway. To quote my son "drive self daddy, drive self." So I lined him up and let him roll at a whopping 5 mph.

This was great test too. I need to lock the rear axle bolts down. They keep trying to turn with the wheel (cheap HF bearings again). Problem is the bolts are not threaded all the way to the head so I can't just snug a lock washer and nut up against the body tub. I might have to buy a threaded rod and use a nylock nut on the inside plus a few lock washers here and there.

So now to figure out how I'm going to make this his "race car" while still being mobile enough to fit in my trunk.

Appleseed wrote: I need this:

with a front mount, chaindrive 12 horse Briggs&Stratton, slingshot style.

Hey guys new on the board. Just thought id share my over kill wagon.

Thanks guy. I started anouther one for a buddy who is havin his first kid. Not as extreme as this one. Ill post pics later

thread bump.

With baby girl due in three weeks I have been busy thinking of things like this. I was skimming craigslist for radio flyers then remembered my radio flyer wagon from when I was a kid is probably still tucked away somewhere in my 'rents garage. going to try and go dig that out this weekend.

Certainly want to lower it, I could probably fab something up (I haz no welder or such skills) but I think my brother in law might be able to weld up a frame for me. Ill take everything apart first and see what I am working with.

Slefain, I cant see most of your pics above, have any you can repost of your build?

You'll need to log in to post.