I've acquired a new-to-me garage (with a house) a few weeks ago. The walls and ceiling are insulated and covered with a vapor barrier, and I'm starting to think about what to use to cover the walls and ceiling. The garage is detached, so I don't necessarily need to do drywall for fire codes. There's also about 40 outlets, so there will be a lot of cutouts to make.

Looking to get some ideas from the hive - if this was your garage, what would you use to cover the walls and ceiling?

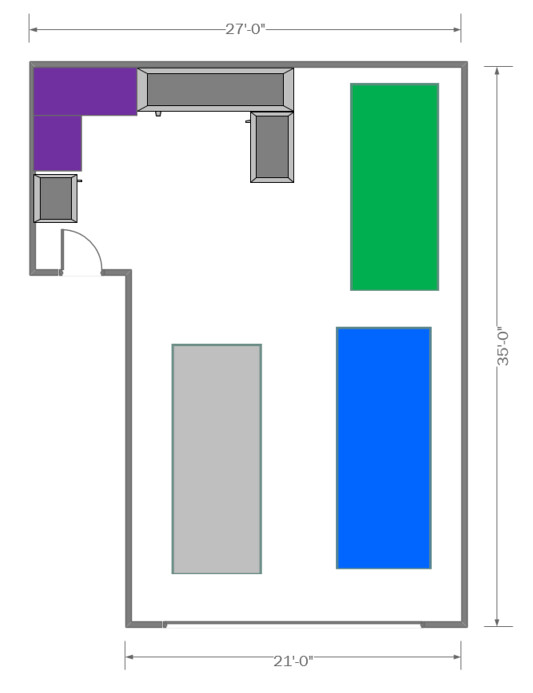

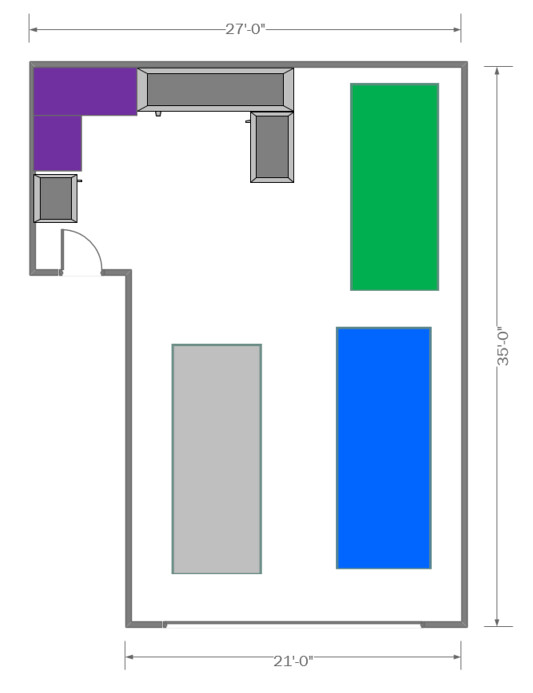

Here's a couple pics and the general layout for inspiration:

Uh droool worthy garage.....

I did OSB, shiny side out. I like it, able to screw anywhere.

From a pure utility standpoint, USB painted white. It looks as good as it needs to, mount stuff anywhere, durable, easy to replace. Also, coat the floor with something first. Uncoated concrete sucks in the long run. Don't be me and fill the garage first.

mtn

MegaDork

1/9/19 1:25 p.m.

I'd go with OSB or Plywood, whatever you can get cheap, then paint it. Maybe even straight pegboard.

I like the sofa placement!

My brother is doing horizontal slats in his garage so he can mount all his storage to interlocking slats and hang stuff pretty much anywhere. He knows he's going to be moving in a few years and that way he can build permanent storage solutions and take them with him when he moves.

For ceilings I like white ribbed steel siding best myself; it's clean, easy, reflects light, and can span weird truss spacing. I'm also kinda partial to it for the bottom third or so of the wall where you aren't typically mounting stuff to the wall for the same reasons.

For the top 2/3 of the wall OSB or underlayment painted with an easy clean up paint and with the double slot shelving brackets hanging down from the top rail on as many studs as I can afford. That way I can get the storage stuff up off the ground and keep the floors clear.

Robbie

UltimaDork

1/9/19 2:00 p.m.

If you wanted to get really fancy you could go with slatwall - basically what commercial retailers use for flexible wall hanging arrangements. Would be about 2x cost of osb or similar to cost of 1/2 plywood looks like.

https://www.menards.com/main/paint/paneling-planking/paneling/dakota-trade-4-x-8-prefinished-slatwall/lamslatwallwhite/p-1444428251813-c-8168.htm?tid=8525791679637621509&ipos=3

Curtis

UltimaDork

1/9/19 3:02 p.m.

If you're just looking for cheap wall covering, Luan or drywall is hard to beat. Both won't be very durable if you bump into it though. Sheet goods are getting bloody expensive these days too.

If simple 4x8 plywood sheets isn't the aesthetic you're going for, you can use a table saw to rip the plywood down into planks then hang them horizontally for a shiplap effect:

Whatever you use, I recommend throwing on some dry erase paint or chalkboard paint to help keep track of everything.

Drywall would be about the least expensive method. People talk about bumping things into the walls and damaging them, but that makes me wonder what they're doing in their garage...

Nugi

Reader

1/9/19 5:50 p.m.

In reply to stuart in mn :

Work? Moving around materials? This is GRM, we do naughty dirty things in the garage that can get messy. I get a spic and span garage, but not a delicate one. Fluids happen, as any parent, mechanic or casual pervert can attest.

I have a low ceiling in my garage, drywalled, gouged to hell. I have often dreamed of painted plywood/chipboard overlay so I can quit having to worry about it so much. These are some good ideas to me.

That said, only once have I gone clear through drywall, but I am also doing repairs once a year, as my home is connected. Not ideal. However, as previously discussed, I am apparently a bit harder on things than most people. Your mileage may wildly vary.

Whichever you use, throw a coat of sealing primer on first. Almost all the options discussed so far suck up paint.

Thanks for the great suggestions everyone! Sounds like OSB is the generally-preferred option. Right now, I'm liking the idea of doing the ceiling in metal like oldopelguy suggested, then doing the walls in OSB, and adding either slatboard or pegboard in strategic areas.

Also a good suggestion from Mazdeuce on coating the floor. I've read the entire grosh thread (it only took about a month!), so I definitely trust his advice! I also love RevRico's advice on dry erase paint on the wall!

Dumb question, but would I need to pull the outlet boxes out a little bit? They seem to be mounted flush with the wall (or lack of wall) - after adding ~1/2" to the wall thickness, would I just need longer screws for the covers, or will I have to pull the boxes out slightly?

Remount the boxes, or find the little extensions that move them out half an inch. I am pretty sure those exist...

That sounds easy enough, thanks Streetwiseguy!

Search for “electrical box extender” that’s what they’re made for. Lowe’s and Home Depot have them as do any electrical supply houses.

You could put a sheet or two of heavy duty peg board on a section of the wall for organizing small stuff.

Drywall is better because when you throw a wrench the wall catches it.

With OSB it can bounce back and hit the windshield of the car you are working on!

Mazdeuce edited this. The poster was wanting you to line the garage with canoes. Weird.

In reply to barrowcadbury :

If you want something with character that looks great and si darn near free go to a local sawmill and buy a truckload of thins.

Thins are boards less than 1 inch thick and because they have no market value you can load your pickup as much as you dare for $10-15 dollars. ( talking looking for squirrels with the headlites loaded)

I first saw that done where the owner mixed a whole variety of different woods and put them up randomly. Cherry, Maple, Oak, Black Walnut, tamarack, hackberry, Ironwood, etc. The look was fascinating. He said it took him a few hours to do and it cost him less than $30.

frenchyd said:

In reply to barrowcadbury :

If you want something with character that looks great and si darn near free go to a local sawmill and buy a truckload of thins.

Thins are boards less than 1 inch thick and because they have no market value you can load your pickup as much as you dare for $10-15 dollars. ( talking looking for squirrels with the headlites loaded)

I first saw that done where the owner mixed a whole variety of different woods and put them up randomly. Cherry, Maple, Oak, Black Walnut, tamarack, hackberry, Ironwood, etc. The look was fascinating. He said it took him a few hours to do and it cost him less than $30.

Wow I need to look into getting thins, is that a common offering at mills? Much easier than pallet hunting and deconstructing with a sawzall. But what do you put under the thins to "hold" them in place, or just cut to fit wall height and screw into sill plate and top plate and studs?

I plan to cover my walls in drywall, wood is astronomically expensive now, and drywall is more sparky-fire-safe. Local drywall shop on corner near me lets you take damaged panels for free, lots are 10ft+ so easily have 8ft of good panel leftover. Ceilings will be metal roofing panels; easy to mount using furring channel across joists, cheap enough, WAY lighter than drywall, can buy in white painted and then no painting of celing required.

I would be keeping my eyes open for stores going out of business and selling off slatwall and fittings.

I've read somewhere that OSB or plywood are no bueno for a garage where sparks might be flying from grinding or welding or such. Drywall may be more fragile, but it's also more fire resistant.

In reply to engiekev :

That's are the result of Mother Nature growing trees at different rates when they need to be harvested at the same time.

Anything less than 1 inch thick will not plane to a 3/4 inch finished board. So trees that are 22& 3/4 inch wide will wind up with a 3/4 thick board.

Normally they are just ground up as mulch so getting anything for them makes sense. There is no one standard thickness which adds to the interest. I've seen standardized width say 4". For one level. And 7" for the next level. Various widths going up the wall. I've also seen a brick effect used. 2 3" boards butted up to one 6 " board etc.

The most interesting ( and labor intensive) was stepped boards. One part would be 2" and another part 5" butted up to a 9" board. And a 2" filler strip to keep everything level. Add the variety of wood available and You can imagine how interesting it will be.