It took some effort, but we're making solid progress.

The engine bay looked surprisingly solid other than the area around the battery tray.

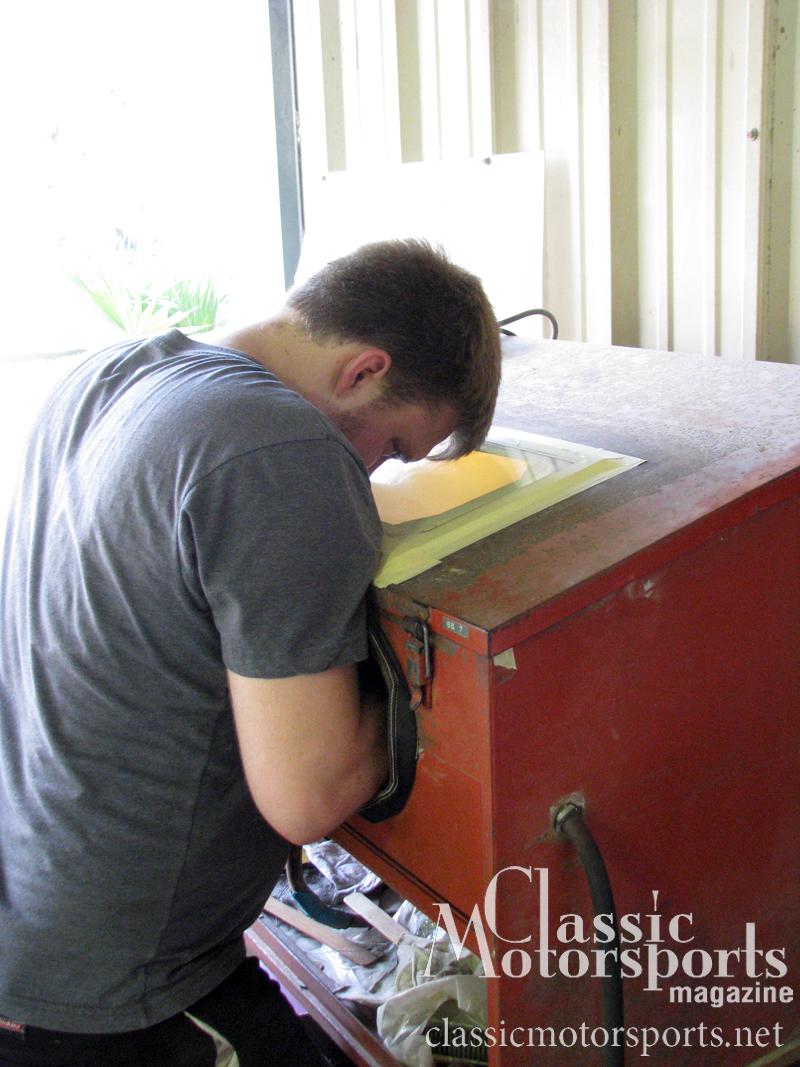

Our intern Matt was already pretty handy with a blast cabinet, but we gave him lots of practice anyway.

What can we say? The young man does good work.

Once they had been stripped and cleaned, we sprayed the new parts with the correct primer for a concours finish.

After one day at Orlando Mustang, we had a nearly stripped chassis. Look at us, we’re making progress.

As parts flew off the Shelby GT 350—remember, speed is of the essence as we have a big date in Montana coming up—we quickly cleaned and cataloged them. Our intern, Matt, manned the parts washer and bead blaster, while Orlando Mustang’s Peter Geisler repainted items like the transmission mount and original Shelby exhaust hangers—yes, even our hangers are original.

In addition to the engine, we also pulled the rest of the driveline. The differential and transmission both need to be rebuilt, but to keep the car mobile we fitted a replacement diff.

While tearing apart the rest of the chassis, we found very few problems. The car had a broken exhaust manifold stud, but our friends at Gary’s Driveline quickly fixed it.

After one day at Orlando Mustang, we had a nearly stripped chassis. Look at us, we’re making progress.

View all comments on the CMS forums

You'll need to log in to post.