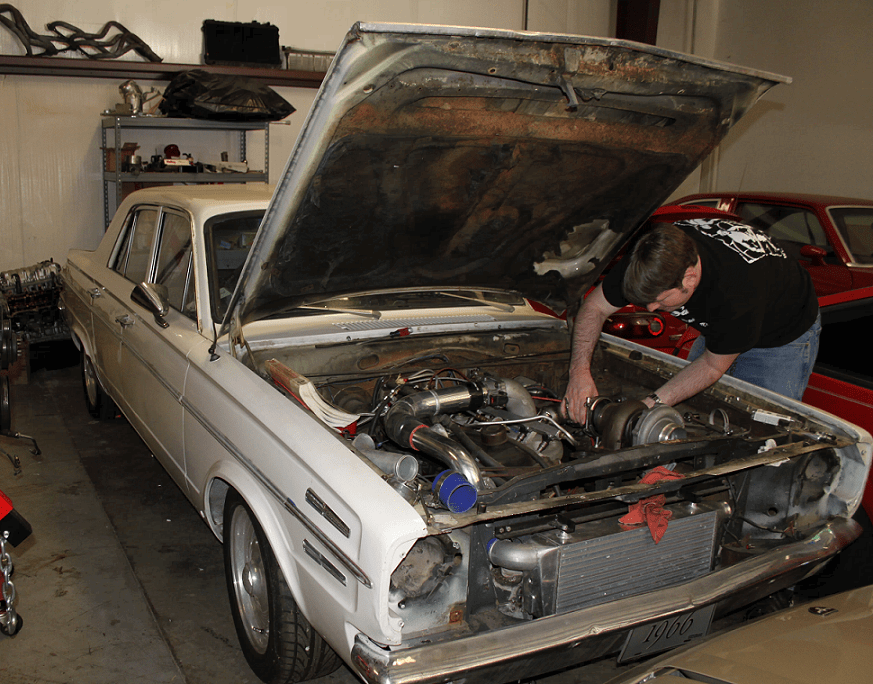

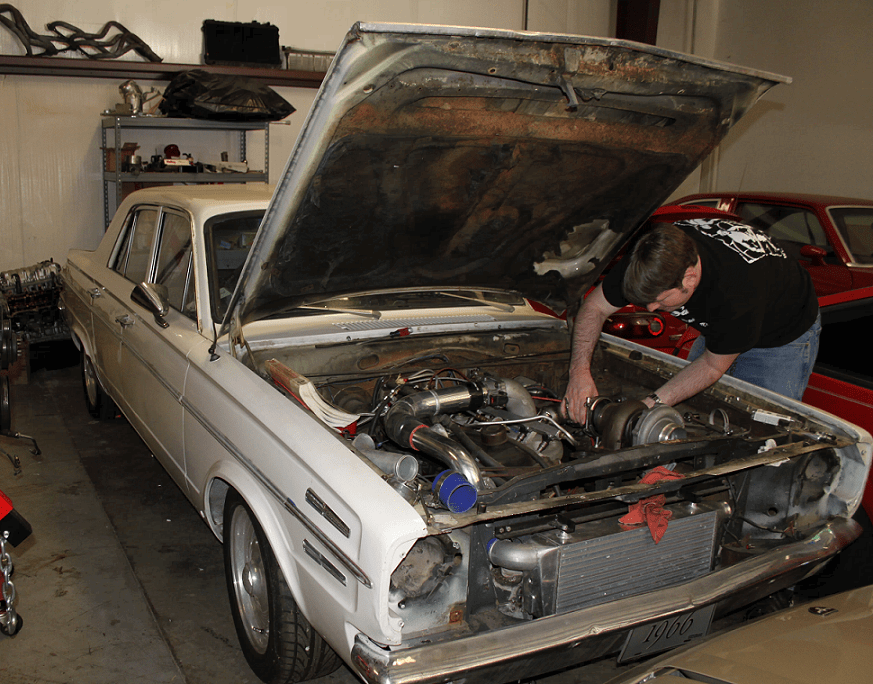

I seem to have lost the original build thread, so I'm creating a new one as the car is getting ready to get back on the road. The car is a 1966 Dodge Dart four door with a slant six and automatic transmission.

It has a few chassis mods - an Addco front sway bar, small block torsion bars, KYB shocks, and 11.75" brakes off a Dodge St. Regis. There's also an 8 3/4" rear axle that I plan to install soon. The engine build is a turbocharged and MegaSquirt equipped 225 cubic inch slant six. I had originally used a K-car turbo and welded manifold bought from the guy who wrote this article. Unfortunately, the turbo would make hard-to-control levels of boost at 1500 RPM and start to feel like a restriction at 3000 RPM. So, it was time for something bigger - a Garrett GT4082.

The installation has been rather drawn out, but is finally close to ready to go on the road again. It's using a Clifford intake reworked for Toyota Supra injectors and a Ford 4.6 throttle body on an adapter made of aluminum plumbing supplies.

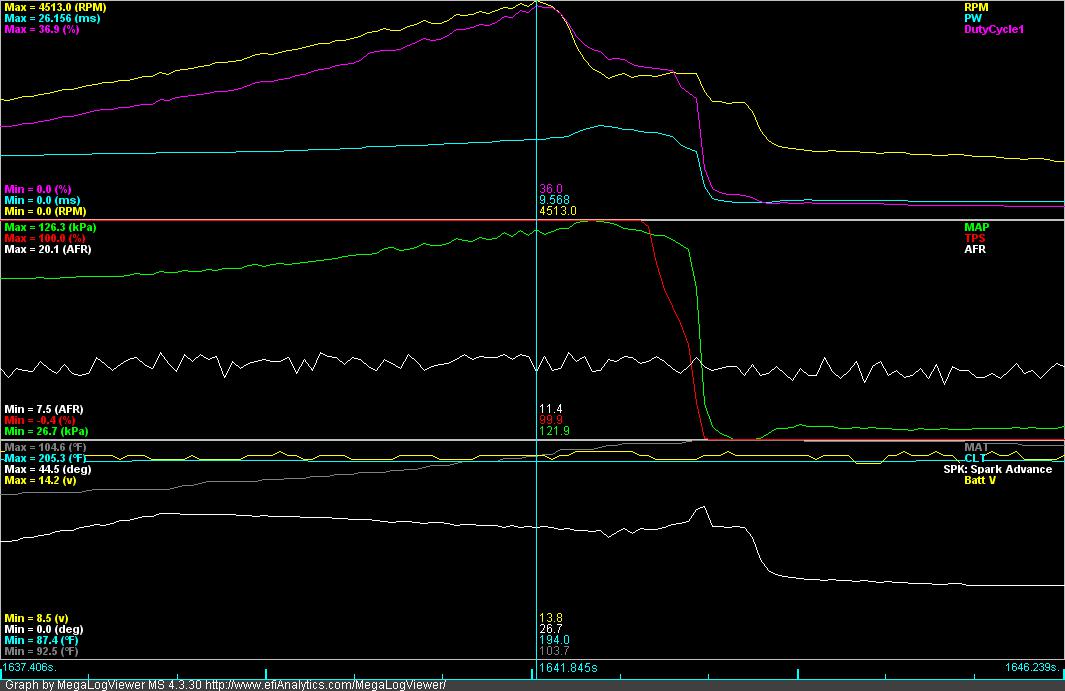

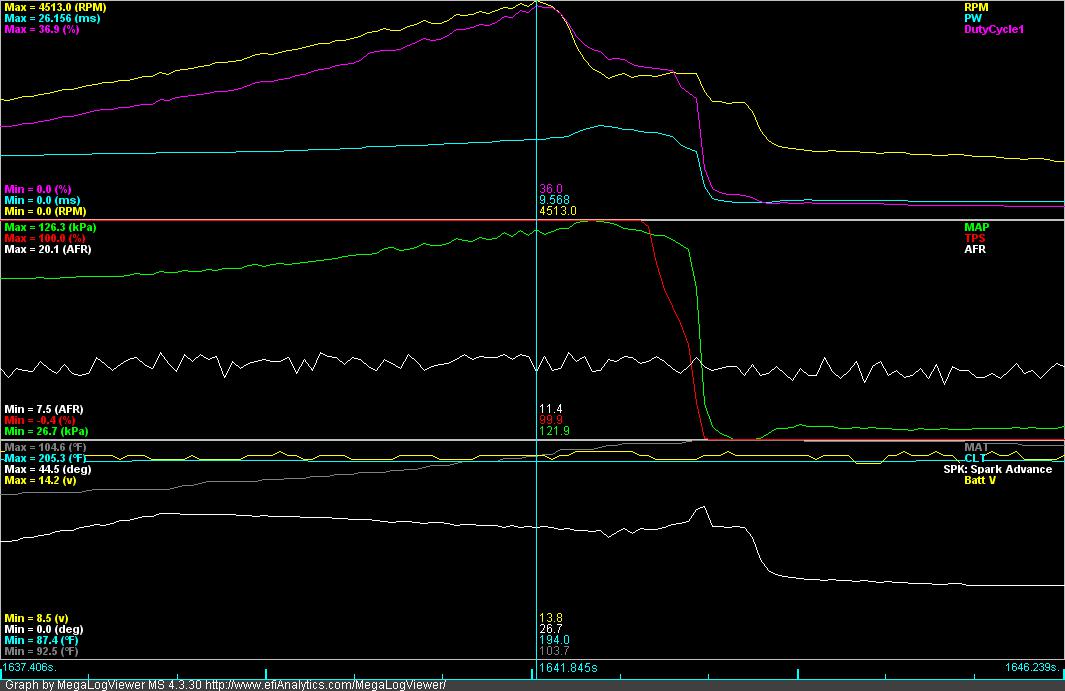

The initial shakedown run revealed that it would not really start making boost until over 3000 RPM.

Unfortunately, it also revealed a rear mail seal leak, so right now I've got the oil pan off changing the seal. There's a couple other things I'd like to replace - the wideband O2 sensor is a bit suspect, for example. After that I'd like to do a bit more of a shakedown run, then it should be ready to go on a dyno.

Looking forward for more updates. Cool project. A turbo seems like a good solution on getting a lot more performance out of an otherwise stock slant-six.

Hard to see the fuel pressure regulator.

Is it referenced to the intake manifold?

Fuel pressure should increase with manifold pressure to maintain the pressure differential across the injector.

Otherwise the injector effectively gets smaller as boost increases.

It's an older Bosch design reworked for hard lines and plumbed to one of the fittings on the intake elbow.

79rex

Reader

9/18/19 1:48 p.m.

watching because i love /6s

This is awesome! I LOVE turbo Slant 6's. A few years ago, I stumbled upon a turbocharged '68 Barracuda after getting some groceries. No, really: https://bangshift.com/general-news/car-features/grocery-store-parking-lot-find-check-turbo-slant-six-plymouth-barracuda-drop-top/

Guy was a retired mechanical engineer that wanted something "different", so he built this. He converted it to EFI using Grand National bits and turbocharged it later on. He wrote an article on SlantSix.org about it as well: http://slantsix.org/articles/dibiase_efi/efi-conversion.htm

Since seeing that, I always wondered how one could do it with MegaSquirt, so I'll be following this closely!

I am helping out mashing up a 300 Ford and a GM4 turbo off a diesel and a Megasquirt.

To go in a 50's Ford for bracket racing and the occasional cruise night.

After looking at it I have the feeling the exhaust housing on the turbo is too small for the 300.

Ohhhh yeah. Will be watching this one with great interest.

Tony Sestito said:

Since seeing that, I always wondered how one could do it with MegaSquirt, so I'll be following this closely!

Here's some more notes on the electronics and fuel delivery package I'm using.

A previous version of the build had used a complex package with two pumps and a surge tank. In this case, I've changed to a single Walbro 255 fuel pump and a sumped fuel tank using a cake pan for a sump. Fuel injectors are Mk III Supra 440 cc parts, with a Bosch D-Jetronic fuel pressure regulator and a throttle body off a 4.6 Ford Crown Victoria.

The car had originally used an MS1 V2.2. Currently on an experimental MS2 variant. For the ignition, I'm using a Lean Burn distributor wired to a 7 pin HEI ignition module, plus a MSD 6AL box. There's a crank trigger on there too, but I haven't yet fabricated a mount for a sensor to use it.

Vigo

MegaDork

9/19/19 10:00 a.m.

Pretty sweet. I emailed you through the board about a related topic since i have a couple of slant6 projects myself.

Are you planning on keeping this turbo or changing out for something sized between this and the old small unit?

Any other major changes you're considering?

Today's update - not looking forward to getting the oil pan back on as it uses a four piece gasket. Dorman makes a set of temporary pins to hold the gaskets in place while attaching the pins; unfortunately no local parts stores have one. I'll get one on order. In the meantime, I made sure the fuel filter was secured a bit better with some zip ties.

pres589 (djronnebaum) said:

Are you planning on keeping this turbo or changing out for something sized between this and the old small unit?

We'll see how much I like the final result when tuning is complete. Using a two step rev limiter may help it spool a bit better.

Any other major changes you're considering?

If I kill this motor, I'd plan a rebuild with a few mods - somewhat more aggressive cam, copper head gasket, and some cylinder head porting. There's more than one way to fix too much turbo.

There's a good chance coil near plug ignition may be in the future. Instead of something modern, I'm tempted to go with a set of six old school can-type coils, then stick six "Orange Box" ignition modules to the inner fender. The orange boxes probably won't be functional so much as just there for the lulz.

The suspension could use some adjustments. I don't like the way the Addco sway bar brackets hang below the K-member and will probably fab up some new brackets. On the rear, I've thought about making a set of slapper bars built specifically to work with the stock suspension geometry. I could go with something more like Cal-Tracs, but slapper bars would be easier to make - and would troll the "never put traction bars on a Mopar!" crowd who didn't fully understand what that rule is trying to prevent.

I'm not sure what, if anything, I will do with the transmission.

bentwrench said:

I am helping out mashing up a 300 Ford and a GM4 turbo off a diesel and a Megasquirt.

To go in a 50's Ford for bracket racing and the occasional cruise night.

After looking at it I have the feeling the exhaust housing on the turbo is too small for the 300.

Fordsix.com you can probably find size recommendations easily.

Leaf rear suspension for handling always seemed kind of challenging. Control axle wrap but don't have a binding situation when it comes to actually turning. Maybe split-mono leaves and a panhard bar + a light sway bar? There's others that know way more about this than I do.

I think the problem with slapper bars is the impact.

The link bars that mount under the spring from the axle to the front mount fix the impact issue but may cause binding (especially turning corners).

I think small tire stuff all has a certain amount of Voo Doo as you are operating over suspension design parameters and at the limits of traction.

It's a balancing act using a stack of bandaids.

Uncle Tony's Garage has made me love the slant 6, and I love the idea of taking an old engine and upgrading it heavily with new tech.

Since you've got a megasquirt, I take it you're running wasted spark and EDIS-6 module, right?

GIRTHQUAKE said:

Since you've got a megasquirt, I take it you're running wasted spark and EDIS-6 module, right?

There are a lot of better options than EDIS now. Not that I'm actually running anything spectacular right now; it's using a Lean Burn distributor, HEI module (which wouldn't be necessary now, but was when I started the build) and an MSD 6A ignition box.

In reply to MadScientistMatt :

best fix for "too much turbo" is "build motor that can use it"

nlevine

New Reader

9/20/19 12:31 p.m.

I learned to drive in a 4-door, white, '66 Dart with a slant-6 (a car that my friends had a funeral procession for when we drove it to the junkyard).

With more power, I'm hoping the front drum brakes are getting upgraded...

nlevine said:

With more power, I'm hoping the front drum brakes are getting upgraded...

They're long gone. I used the '70s land yacht disc brake swap pioneered by Mopar Action. Rear currently has 10" drums and the new axle will upgrade that to 11".

MadScientistMatt said:

GIRTHQUAKE said:

Since you've got a megasquirt, I take it you're running wasted spark and EDIS-6 module, right?

There are a lot of better options than EDIS now. Not that I'm actually running anything spectacular right now; it's using a Lean Burn distributor, HEI module (which wouldn't be necessary now, but was when I started the build) and an MSD 6A ignition box.

Okay! Do you mind explaining more to me about it? I started looking into this and found that the older EDIS system makes for a wasted spark and batch fired injectors- I think yours offers sequential and better spark?

Using the Mopar distributors with MegaSquirt is covered here: https://www.diyautotune.com/support/tech/install/mopar/megasquirt-vintage-ignitions/

The higher end ignitions are basically mix and match - you configure the MegaSquirt for the inputs (crank and cam triggers) and outputs (distributor, coil on plug, etc) separately. The main drawbacks with EDIS are that it wouldn't do a spark cut rev limiter and that some of the EDIS modules appear to have built in rev limiter behavior, such as stopping sending the ECU an RPM signal at a predetermined point that is hard coded into the EDIS module. And unfortunately these sorts of cuts aren't very well documented.

No disrespect to the leaning tower of power, but I have doubts that a hard-coded rev limit in an EDIS-6 module would really limit a non-seriously built /6.

Reading through this thread yesterday had me doing mental gymnastics on what it would take to adapt a GM 5L50 to one of these. Unfortunately I lack tools and ability to make that happen or a car to put this in.

Stefan

MegaDork

9/20/19 4:08 p.m.

In reply to GIRTHQUAKE :

Basically people used the EDIS module to drive the coil pack and accept the crank signal as it was an easy way to move away from using a distributor or integrate into an existing Ford EDIS solution. You could set it to a default 10BTDC for diagnosing issues, etc. but it just creates more potential failures and undocumented options like Matt mentioned.

That has been mostly superseded by simply driving the coil pack(s) directly from MegaSquirt with an ignition driver, the crank sensor input goes directly to the MegaSquirt. This also opens up the options for other coil types/solutions.

You need to extend the stock code to make full use of this and the various options are documented here: http://www.msextra.com/manuals/

pres589 (djronnebaum) said:

No disrespect to the leaning tower of power, but I have doubts that a hard-coded rev limit in an EDIS-6 module would really limit a non-seriously built /6.

I'm planning to do some experimentation with a spark cut two step rev limiter, which EDIS won't support.