Even though it's pretty far along, I thought I should start a build thread for this project. Maybe someone will learn something (including me). This car has been in development since 1999 or so. First, this is actually a friend's car that we've been working on together. It started originally as a $600 car with brand new Michelin Redline reproductions, themselves worth the purchase price. After welding in some new floorpans and rockers, the chassis was pretty much rust free. The frame is as clean and straight as any I've seen. That said, it flexes like crazy at an autocross.

The car was originally set up for autocross with a rebuilt motor and triple Weber DCOE 40 carbs (gotta love intake howl). Once the jetting was sorted, it ran fairly well and revved better than any TR6 I've ever driven, mostly due to an aluminum flywheel and head work. The suspension has many Richard Good upgrades including springs, sways, Spax adjustable front shocks and adjusted rear lever shocks (thanks to JK Jackson). Front hubs and stub axles are upgraded, and the rear hubs are adapted from a Corvair. Front brake calipers are from a 1980-something Toyota 4-Runner, necessitating a larger Jaguar brake master cylinder. Rear brakes use Datsun 240Z alfin drums with Austin Healey larger bore wheel cylinders. We added an Electromotive HPV-1 ignition early on with good results. The wasted-spark setup helped burn some (but not all) of the extra fuel the Webers dumped into the engine. Plus, ignition timing was spot on compared to the original Lucas distributor.

The car ran like this from 2001 until sometime in 2009 when the oil pressure began dropping. Power was still good, but running an engine at 6000 RPM with only 35 PSI of oil pressure is not a recipe for success. The motor was pulled and disassembled showing that the cam was wiped with major pitting/erosion. Some of the debris must have ended up in the oil pump making it work less than good. Surprisingly the rest of the motor, including the bearings, were in good shape. We're still not certain what led to this. Perhaps using oil without ZDDP for some amount of time. Possibly gas getting into the oil, reducing it's ability to deal with a high-lift cam. In any event, the motor was rebuilt. A crank scraper and oil pan baffle were added to help keep oil pressure steady (another possible cause of the cam failure).

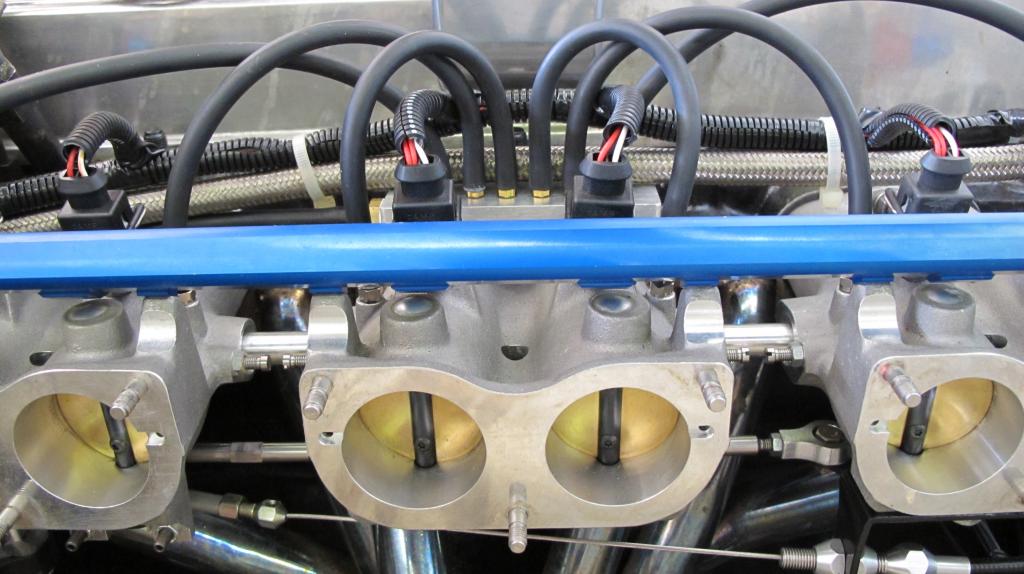

We are now using Brad Penn oil, but the Webers would still continue to wash down the cylinder walls with fuel. That's when we decided to try modern fuel injection. Engine rebuilds aren't cheap, but neither are fuel injection kits. I choose to use a Megasquirt ECU and a TWM/Borla intake. I considered attempting to make my own intake, but this was just too much time/effort on my limited time/knowledge budget. Once these were acquired, the engine was refitted with the Webers for break-in. A wide-band O2 sensor was added (replacing a narrow-band used for "tuning" earlier). This helped dial in the Webers much better than before. Almost enough to make me want to stick with them. Bah, what's the fun in that.

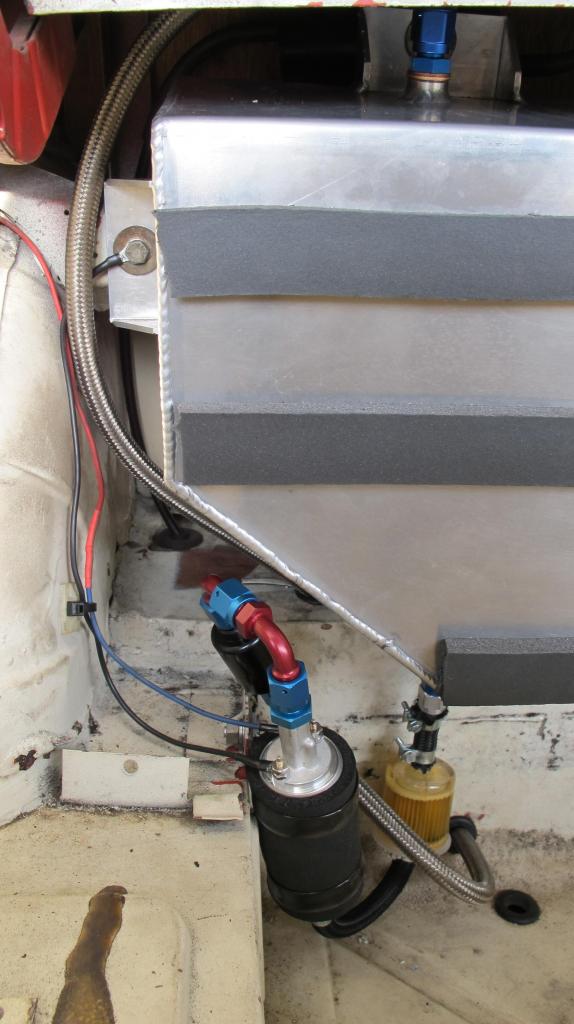

Once the engine had 600+ miles on it, we installed the Megasquirt running just the ignition. This allowed checking all of the sensors without quite so many variables to get right. So far so good, the intake was bolted up. It turns out our tubular header has much larger radius bends than the stock header, so the TPS wiring plug and throttle linkage ran into the header. Nothing some JB Weld on the throttle shaft wouldn't fix (to relocate the flat spot). Actually, this caused a reroute of the throttle cable towards the front of the motor in order to eliminate a bell crank in the linkage. This was fixed with a custom bracket and longer cable. While installing the new intake, the O2 sensor was moved as close as possible to the engine directly on top of the 6-to-1 collector. This made the O2 sensor a bit more responsive and keeps it away from moisture in the exhaust. New 3/8" fuel lines were added to keep the fuel flowing and provide a return line. The aluminum fuel tank has baffles and a built-in anti-surge reservoir.

First start-up running fuel injection was last weekend. Now it's simply (hah) a matter of tuning and fixing all of the issues from the install, such as grounding the crank VR sensor shield wire to the Megasquirt. The original MAP sensor port was drilled into the end of the manifold balance tube. This provided a very noisy signal, so I made a vacuum manifold from some aluminum bar stock. This ties the six individual vacuum ports to a single outlet via a small (7/16" round x 3") cavity. Adding a restrictor between the vacuum manifold and the MAP sensor doesn't appear to be necessary based upon TunerStudio logs. The intake has 45mm throttles, so that coupled with an aggressive cam gives an idle vacuum of 55 KPa. But it responds well to throttle and is fairly smooth. One thing I've only played with a bit is acceleration enrichment. I've added enough fuel and duration to keep the engine running when the throttle is opened, but it still goes fairly lean. I'm currently using alpha-N for engine load, but will eventually go back to trying the ITB load scheme that MS 3 supports.

And that's where this project is at the moment. Pretty soon we'll need an air box to keep from FODing the engine while trying out TunerSudio's autotune feature. I'm working on that this week along with getting some pictures of progress so far.