Ok, before tig guy:

Stitch weld the whole thing. Everything you can get to, up to and including the taillight panel. It adds monumental amounts of structure to the car, and makes the suspension and brakes actually work. I cannot stress enough how much this helps.

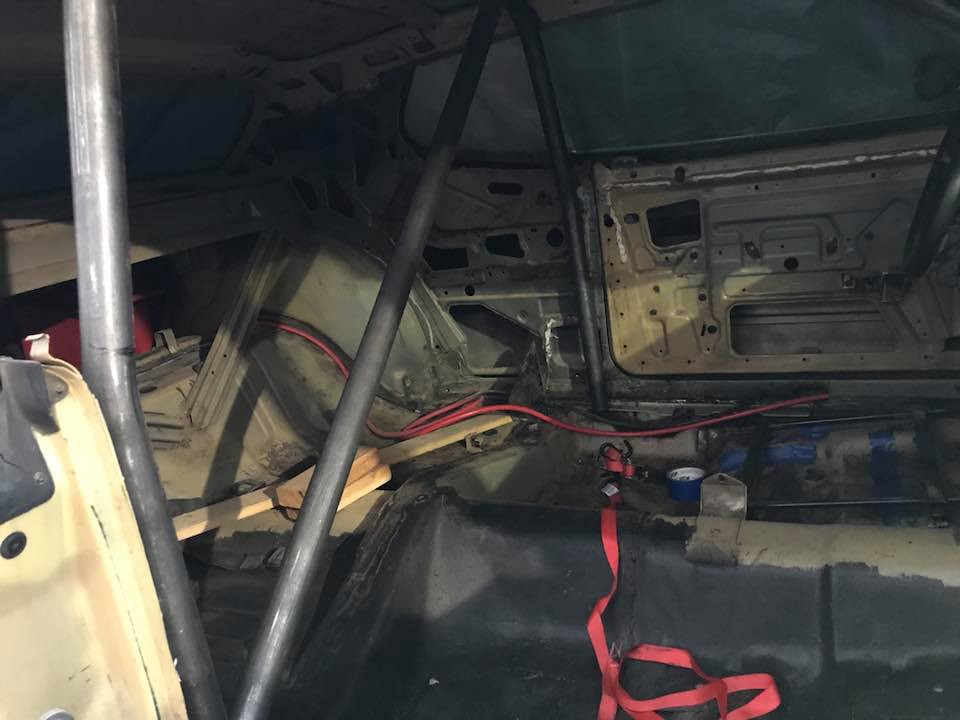

The cage design you have so far looks pretty good. Try to tie the main hoop at the front spring eyes, the rear downtubes at the reah spring hangar, the fronts downtubes to just in front of the leading edge of the k frame, and the a pillar bars as close to the torsion bar crossmember as possible.

Im going off memory for most of this, as its been close to 15 years since I last screwed much with a later b body. So, some points may be optional....

After the cage and stitch welding, pull the full suspension. Up front, machine some steel or aluminium to replace the rubber mounts on the k frame (or is that the later b?). Then, fully weld the k. Take a look at firm feel website to get an idea of the additional gussets and braces they add. Toss the stock strut rods, as they bind significantly. I chose qa1 based in price and design. Seem to be good pieces. (Im primarily an a body guy). Firm feel stage 3 power steering box with their quick ratio arms are a wonderful combination. Ditch the stock column coupler, and grab a speedwar u joint. Id have to look through the duster build thread for a part number, but it was 40 bucks or so well spent. Take the lower comtrol arms, box them. If you can get a needle roller bearing fabbed in instead of the bushing, it provides huge dividends. However, thats race only in my opinion. The moog rubber ones are fine otherwise. Combine your disc splindles with some afco screw in Chrysler type extended length ball joints to fix the camber curve, and moog offset uca bushings to fix caster. Depending on radial vs bias ply slicks will dictate alignment settings. Spax and koni are the good shocks. Dont be tempted by the bilsteiens. They are valved to make up for all the flex in the chassis, and wont react well to a properly stiff car. As far as torsion bars, 1.2x is where i would start.

In the rear, assuming 8.75 axle, youre job is pretty simple. Check the welds on the housing. A lot of them are found to be pretty bad. Leaf springs, built to match the rate you want (id guess 200-250lb) are simple. Either xhd mopar, two right side super stocks, landrum composite, or what i did: hybrid pack of muscle car and durango with a half leaf on the top of the main leaf to control brake hop. Go with a spherical bearing in the front eye, bearing style leaf spring slider instead of shackles, lowering blocks to desired ride height, and go. Clamp all leaves in the front segment, and get the pinion snubber properly adjusted.

Im not a purist by the way....