CrustyRedXpress... Love the "CRX" buried in ur avatar.. Been a long ride. Glad she's held up...

The 3rd 2023 Road Trip got altered. Flew to NYC last month to pick up a car for my daughter and drove it back to TX.

I tried as hard as I could to keep her in a CRX. When a little girl, she'd sit on my lap and we'd drive around the neighborhood. As soon as her feet were long enough she practiced on the manual transmission. Little kids always seem to be happy behind the wheel.

drivers

drivers

We did parent taught drivers ED together in this car. Some of the best conversations on those trips..

And she drove off in the CRX the first day as a licensed driver.

I didnt expect to get her into a CRX, but she bought a Civic -- I'll take that... A family friends neighbor was moving. Little old lady. 2017 w 17K miles kept in the garage. Was worth the trip to get her in this car.

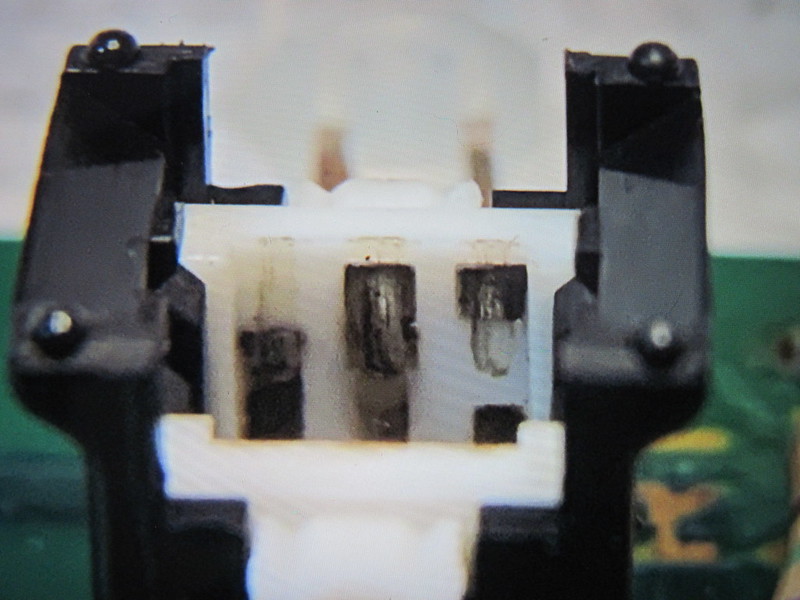

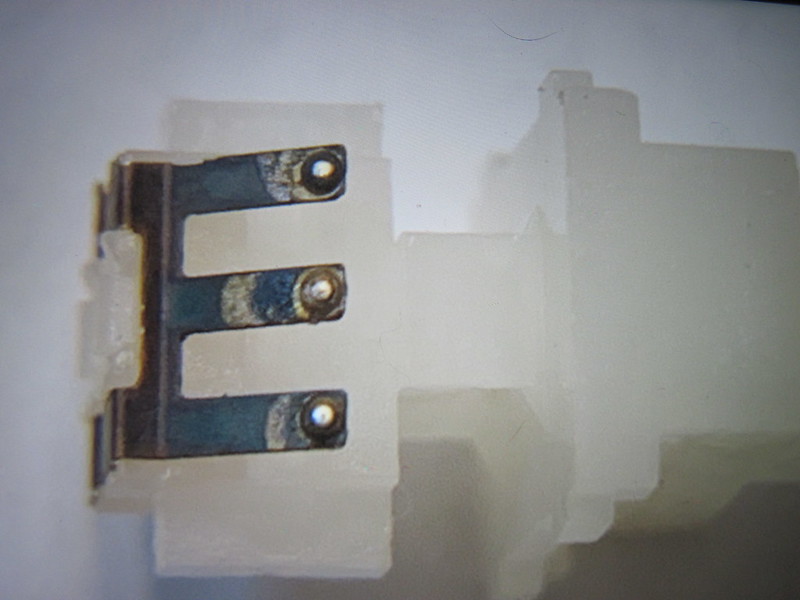

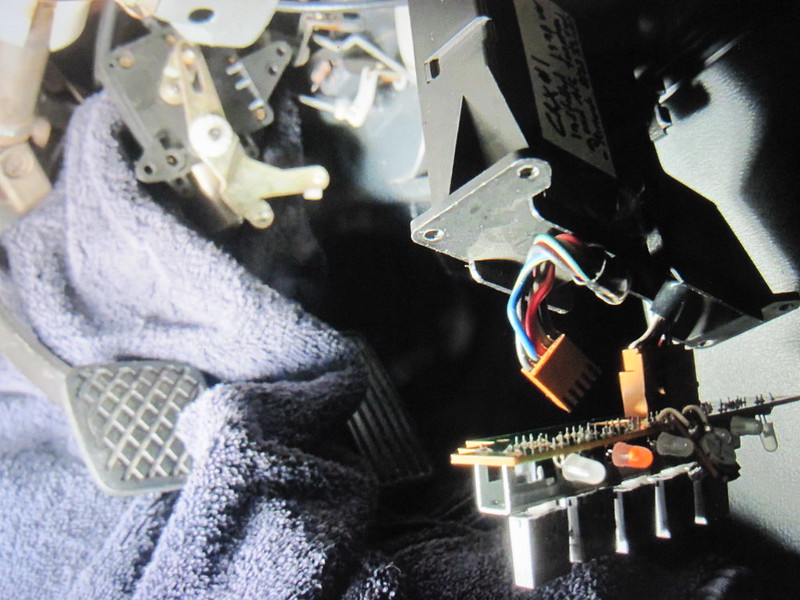

Been pretty quiet on the car side of things. Took the dremmel to the alternator w the cracked case (MadMaxCRX#3 108k). Once I began the cut the housing away, it popped right open. The theory of corrosion of the aluminum appears to be the case. The aluminum housing and stator base both appeared to corrode creating interference like water freezing in a cracked sidewalk.. Forcing the coil to warp a little and crack the case. Lesson learned for me, when the alternators rotor begins to drag, pull out of service and replace. Thinking the same issue caused BeaterCRX#1's original alternator to lock its rotor. Both of these alternators were used in northern, salty environments. Guessing this accelerated the issue.

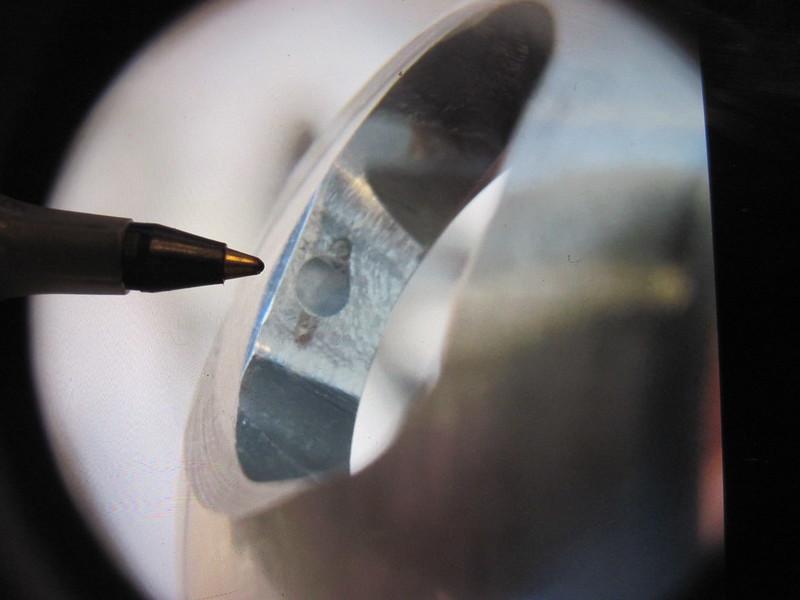

On last fall's Michigan trip, had to drive in the rain for 3 days toward the end of the trip. As I rule, I don't drive this car in the rain due to the water leaks. The carpets were pretty damp after unpacking. Pulled the carpet aside to dry out after the trip. I knew I had compromised seams around the floor board. Shined a flashlight from underneath. Can clearly see the light coming through at the pencil tip. For now, I'm going to use windshield sealant to reseal the seems. The cars been stored relatively dry the past 20 years and barely driven in the rain. I'm sure this has gotten a little worse over the years from humidity. I need to look at this closer. I've been having some strange interference issues with the door. Assumed hinges/door strikes. Maybe its more??

ROAD TRIP 2024 will kick off in February. Heading to Florida again. 2000 miles ish.

Oil's changed. Need to address water leaks, remove/wash the carpet for the musty smell, inspect the drivers tie rod bellow as a small crack was starting, figure out the drivers door interference w the door jam. And was getting a little humming from the drivers front wheel bearing area. Not sure if my attempt to straighten the axle was a good choice....