SUMMIT POINT: NASA Spring Rumble, April 21-22, 2018

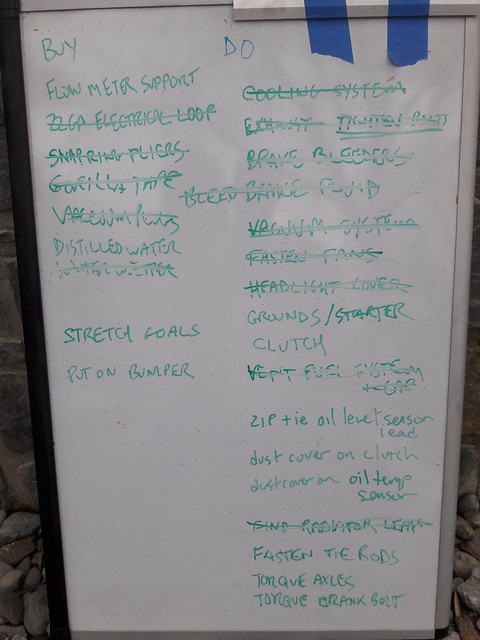

The Thursday night and Friday before the event, I got all my stuff done... except re-bleeding the brakes and clutch. I got the track packed, and took off for the track on Saturday morning. On the way I filled the car with gas so I could do some fuel/weight management.

My car started up fine and passed inspection. Yay 2018 tech sticker! That felt pretty good.

On Saturday, racers get a 25 minute warmup session, a 15 minute qualifying session, and a 25 minute race. On Sunday no warmup, but a 40 minute race.

SATURDAY WARMUP: BREAKDOWN

During warmup, I got all the way around the track one time, but the car died on me and backfired a few times at turn five. I pulled as far as I could into the infield and watched other racers pass me by for 20 minutes before getting a tow into the paddock at the end of the session.

I discovered my distributor rotor and cap were both loose. When I took off the cap, the rotor screw fell out and onto the ground. Turns out I installed that cap upside down, and it just fits better when it's installed correctly. I fixed all of that, including some blue loctite on that screw, and the car started right up.

On a scale of 1-10, my confidence in my car was about an 8. Maybe 7.

QUALIFYING: WHAT'S THAT SMELL?

I got a couple laps into qualifying and I started to smell gas in the cabin. That's not usually a good thing in any car, but in a 944, where the fuel lines cross directly over the hot header pipes, it can be catastrophic. So I pulled into the paddock early to investigate.

Good news: the engine bay was dry. Turns out the gas cap was spewing gas on turns and was draining through the drain tubes inside the car, but not quite all the way OUT of the car. Not a big problem. I drained five gallons out of the car and decided that wouldn't be a problem anymore.

On a scale of 1-10, my confidence in my car was about a 6. Maybe.

RACE: BREAKDOWN BEFORE THE START

As we pitted out onto the front straight, I had only done a brake check and some tire-warming swerves before the car suddenly entered what felt like limp-mode. If I added throttle, it felt like the car was actually trying to slow itself down. Fortunately it made it all the way around the track and into the paddock. I never even saw the race start, which was disappointing becuase it would have been my first standing-start race.

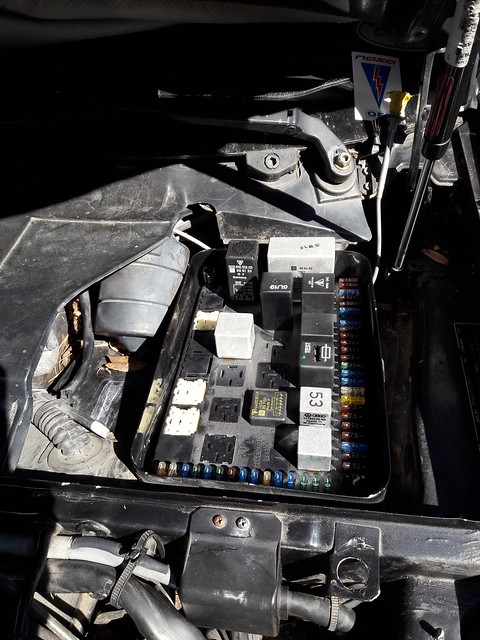

In the paddock, I found the piece of JB-Welded screw was gone. The computer must have been able to keep it going on sheer guesswork.

At least the car failed where everyone would have expected it to fail. If that's any consolation.

A DAY OF DISAPPOINTMENT, WITH SOME HOPE

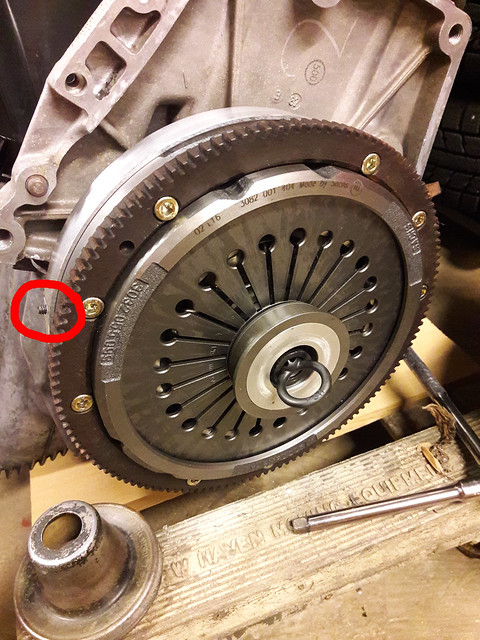

It was a disappointing day overall, but I did get a couple semi-hot laps in, bedding in the clutch, bedding in the brakes, and shaking down a few issues.

I didn't feel terrible about my engine build and car preparation. A LOT of things had to go right to get as far as I did this weekend. The goal is a reliable car with a reliable engine, and that goal isn't necessarily out of reach. It just wasn't meant to be THIS weekend.