A question,

I noticed a distinct lack of GRM stickers on your car....

Vacation took its turn, and now it's the 944's turn again.

Today I installed a used hitch receiver which kills two birds... I can now tow a tire trailer to Watkins Glen at the end of this month, and the receiver can double as a tow hook for the track.

Noises, New and Old

About five miles from home on the way back from my last track day, the rear end began making a TICK-TICK-TICK sound, only on acceleration or engine braking. Coasting, or in neutral, it was quiet. So I suspect I have a bad or dirty CV joint. Hopefully I don't have to replace anything, but it's going to be a very messy job and I don't look forward to it.

An old noise is the terrible sounds emanating from the muffler. Despite replacing the perforated test pipe with a solid one, the exhaust still sounds like poo. There are two possible culprits left: the header and the resonator. I have to think there are pieces rattling around in the resonator, so I'm going to delete it, piping 2 1/2" all the way back from the test pipe to the muffler (in a recent post above, I was incorrect; wherever I said 3" vs. 2 1/2", I meant to say 2 1/2" vs 2 1/4").

I'm also going to carefully inspect the integrity of the header.

A checklist, of sorts:

1) Fix CV joint noise.

2) Inspect the header.

3) Pipe 2 1/2" stainless all the way from the test pipe to the muffler (resonator delete).

4) More carpet removal and cleanup.

5) Build my tire trailer (I bought the Harbor Freight 40x48 trailer with the big tires). Wire the lights in the car (all the necessary wiring was provided with my used hitch receiver, thankfully).

6) Nut and Bolt the entire suspension.

7) Take it in for a pre-track inspection from Intersport Performance.

So far, I've always self-inspected on this car and my Fiesta. But I'm interested to see what they discover with and what they recommend. Plus, it's complimentary.

Flight Service wrote: A question, I noticed a distinct lack of GRM stickers on your car....

You would think that this would be number one on my checklist...

...You would be right.

Inspecting the rear end noise:

Tonight I took the axles off the car and they both feel really solid and tight in all the range of their motion. I'm going to go ahead and rebuild all the joints since I have them off, but what a mess they are. It seemed like it took half a roll of paper towels just to clean off the transaxle and outer axle cups.

The transaxle itself may be the source of the noise. It's a little noisy as it turns (it feels/sounds like the feel/sound of gears meshing together, not terribly "grindy"), but I don't know what's normal. What could be the source of the TICK TICK TICK sound is the fact that I can move either of the transaxle cups in and out (towards and away from the wheels) about 1/16" on each side, and I can make a "tick" sound in both directions as I do it. Again, however, I don't know if that's normal or how much axial play is normal.

Maybe it just needs an adjustment or a shim inside that transaxle? My next job will be to check the transaxle oil level, and then draining the gear oil out to see its condition. Then I'll filter it and put it right back in if it looks ok. I mean, that's $40 worth of gear oil that I just put in there four track weekends ago.

I'm posting this on Rennlist to get the 944 world's opinions on this, but please weigh in if you have any experience with water cooled Porsche transaxles.

How I Found the Rear End Noise

I rebuilt all four CV joints, inspected the connection at the torque tube, rebuilt and re-hung most of my exhaust, and pretty much determined that the only cause of my noise could be the transaxle.

I had an appointment with Charlie (my Porsche Whisperer) for his opinion, and the morning I was to bring it in, the differential pinion failed catastrophically as I pulled away from my brother's house (just three blocks away from my house). I'm just happy it didn't happen after I got out on the highway, or worse, coming back on the highway after paying for a diagnosis!

Diagnosis: Confirmed

I bought a used one to replace it from Just Joshin' Porsche 944 Parts which is about 90 minutes away from me...

So I have a running car again!

Race School Preparation: Driver

Now it's on to making myself and the car legal according to NASA GCR...

I bought a race suit, helmet, gloves, shoes, HANS, window net, and driver net at OG Racing (thanks Brian!)

Also I have scheduled an appointment for my medical exam.

Race School Preparation: Car

I'll need to install the window net and driver net hardware, and I'll need to install my fire extinguisher within reach of the driver, and a rear tow strap.

I am thinking about using one of the old submarine straps from the harnesses that came with the car for that, and I did some practice sewing to give it a couple loops. One end will go into the tow hitch receiver on the car... the other end will hang out JDM style.

I also have an appointment one week from today to have my cage assessed by RRT Racing. The bolt-in cage only has one driver door bar, so it's going to need one added, or the existing driver door bar will need replacement with two bars. I can't go into the door card because I need the windows to be operable. This car isn't garaged.

I would probably do the work myself but I don't have a tubing bender. And I'm happy enough to leave important cage work to the pros.

The rules also state that the shoulder harness bar must intersect with the diagonal of the main hoop. The harness bar that I have added to my car does not intersect that diagonal. The rules are pretty clear about this, although the intent isn't as clear. So we'll see what the experts at RRT have to say about that.

Other than that, the car should be ready for racing!

GTS-1 Series Preparation

The car should fall pretty nicely into GTS-1 class since it's all wrong for 944 Cup. But GTS is a power/weight ruled class (for the most part) so I am going to bring the car to NASA's D-day Dogfight at Summit Point. There I'll get the car on the dyno and have it weighed. And I also hope to get some preparation advice from all the tech experts there.

So I took the car to RRT and got a quote for door bars, net installation, and shoulder harness bars that adhere to the rules. Wayne was really helpful and showed me some examples of door bar designs that would likely work in my 944. The quote he came up with was rather high and although RRT is known for their great work, I had to A) at least determine that the car would pass tech before I sank any money into it, and B) get some competing quotes for similar work.

Then I took the car to NASA's event at Summit Point, and I was happy to learn that with the appropriate cage work, the car would be legal. So no surprises, fortunately. But I was a little disheartened by some opinions I was given about the car.

A couple of the guys said if it were them, they'd sell it and get something with a logbook already, in a better subscribed class such as SpecE30, SpecE36, or CMC. Those happen to be the more popular classes in our region of NASA. In GTS-1, I'd be in a class of one or two cars, and I wouldn't really learn how to race in such a class. I'd be managing traffic and trying not to affect other classes' races.

I was also kind of miffed that nobody told me there would be no dyno machine at the event, even though I sent email to several of the organizers well ahead of time. I left the event kind of downtrodden... I didn't even weigh the car.

But I did get the contact info of another local fabricator who seemed a lot more reasonably priced when I talked to him the following week. So I felt a lot better knowing I wouldn't be dropping four figures on a few welds. And with some pep-talks from some friends, I decided on a new plan for the car, which may eventually involve racing with Porsche Club in SP2 class. We'll see!

Along the way I installed a Rogue Engineering quick-release so I can get out of the car faster despite two door bars:

I've decided on a bent-X doorbar that protrudes into a handy pocket in the door. By removing the stock door pulls, the niche will perfectly accommodate the new door bars. Plus I get to keep the PLAID!!!!

Prepping the car for its door bar installation by removing the seat, the existing bolt-in door bar, and the bolt-in points:

I am being careful not to remove any cage tube... I'll probably leave lumps there and the fabricator can remove it if he finds he needs to.

Carpet is coming out next, and I'm going to do the bars on both sides so I'll be providing my passenger the same level of protection. So I'll have to do the same to the other side.

Here's the passenger side removed. I've removed the door pull / armrest too.

The driver's side carpet has been removed.

I brought the car to the fabricator today, and I've asked him to go ahead and do the following:

1) X door bars on both sides with sheet metal gussets

2) new harness bars for both the driver and passenger that "intersect with the diagonal of the main hoop"

3) window net installation w/ attachment points

4) driver seat mount points which will bring the seat as close to the floor as possible

I'm having him go ahead and do the last two items because I couldn't possibly do it as efficiently as he can.

I am very happy.

Yet I'm feeling a little overwhelmed by the remaining work that I'll need to do before July 22.

But here's a big reason I'm happy: I picked up the 944 from the fabricator, and I learned he has a website: CageFab.com

Jedd did a fantastic job on the X-bars! They're exactly as we discussed and just what I envisioned:

They fit right into the pocket, they hug the rockers, and I can still actually get in and out of the car with the steering wheel on, although it's a lot easier to get out after removing it.

And he installed the window net perfectly... its poles are made of stainless and the lower rod drops out of the way.

One of the things Jedd discovered was that the anti-submarine belt attachment point was actually bolted to a disk of steel that's just glued in. The driver's side was actually beginning to pull out. And in the event of an accident, it would have been useless.

So he relocated both anti-sub attachments to a stronger location with a nice plate for extra strength.

In fact, he couldn't weld in the old hole without attaching his ground directly to the plate - it wouldn't even conduct through the glue holding it in.

Jedd and I decided it would be best to just remove the old shoulder harness bars and the entire diagonal, all of which had end cap slugs (very heavy) bolted to tabs welded to the cage (not all that strong).

So he cut it all out and welded in a new diagonal to attach the new shoulder harness bars. NASA GCR rules require that the harness bars intersect the main hoop diagonal, and these satisfy that requirement.

Now that the straight bar that I had put in has been cut out, I think I can fit four race tires in the car!

One of the things that I'm most excited about is the addition of a solid set of seat mounts, in a place that buys me at least a couple inches above my head. Jedd and I marked the previous location of the seat and I was a little concerned about not being there to double-check the driving position just before he committed to the final seat location, but it wasn't a problem at all. When I came to pick up the car, it was perfect.

The new perspective driving home was surprising though. I had to re-adjust all the mirrors! :-)

Now the seat is SOLID! The removal of the slides really made them feel more like they're part of the car. The hardware itself is also much more robust than the little screws that came with the brackets.

Next: A lot of cleaning and surface prep, and I've ordered paint for the interior of the car and the cage.

Also left to do:

install the inside driver net

secure the sunroof with weld-on tabs

install the fire extinguisher within reach of the driver

I'm feeling pretty confident that the car will be ready by July 22, which is my competition licensing school at Dominion Raceway. The big question is, will the track be ready for me?

A heat gun is a much better way to remove this sound deadening material than the way I was doing it with the multipurpose oscillating tool. Just a putty knife and some paint thinner later, and it looks pretty clean, at least where there's no panel adhesive.

I finally removed the center console. To do so, I had to pretty much spill the wiring out. It's about what I expected. Not an "impeccable build" (the seller's words). Time to fab up a cleaner panel with some proper terminal blocks.

At the center of that last photo is a short section of garden hose used as a sort of insulating sleeve. Nice.

Securing the Moonroof

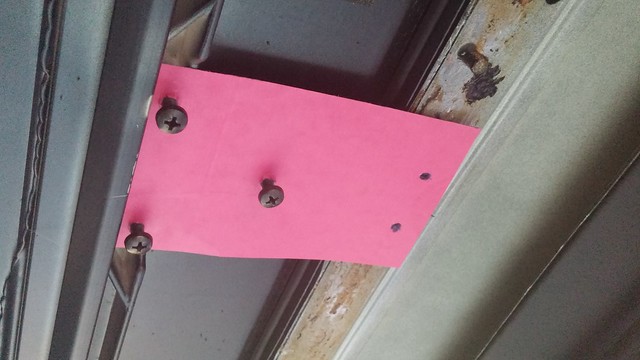

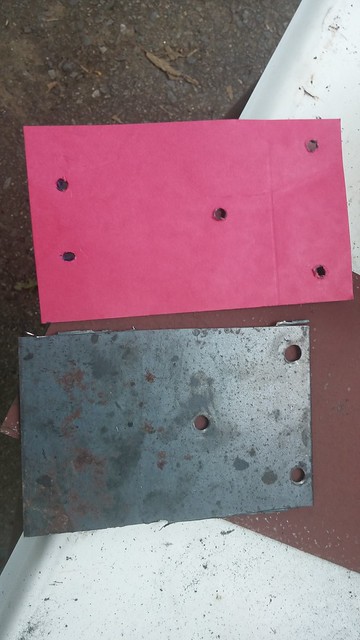

The sunroof has a steel outer skin and a cast aluminum inner skin that's bonded to it with panel adhesive. So I couldn't weld anything directly to the panel from the inside. So I fabricated some plates that secure the panel so that it's inoperable. I used CAD to design the plates so they would take advantage of the bosses in the aluminum casting that you see here. There are steel inserts cast into the panel.

(CAD means Cardboard Aided Design... Check out "Project Binky" for more uses of "CAD")

The rear ones were a little trickier because the bosses in the panel face back instead of down. So I had to make some bends.

To actually put the panel on the car, you need to attach the rear brackets, ease the panel in (brackets first), and then fasten the rear brackets and attach the front brackets. I think it worked out pretty well.

More "CAD" Design on the Electrical Panel

All those switches and stuff looked pretty crappy to begin with. I didn't like the way they were laid out.

So I've begun a panel using some stainless countertop that came off of some medical anesthesia delivery machines, which is just the right gauge for a panel that's got to support at least one heavy switch and a start button. Start buttons can get some abuse when you're stalled after a spinout. Don't ask me how I know that.

I don't have a break so I had to beat on it against my vise with a small sledge to make the bends. It's kind of beat up as a result, but we'll see how it looks after I hit it with a wire wheel for that brushed look. If it still looks like poo, I'll cover it with some faux carbon fiber vinyl I have.

I just wish I had the right tool for cutting out that large 2" diameter gauge hole. It's going to be a long evening with the bastard file.

coming along so nice! cage work is great looking.

uhhh it may be worth the drive for a hole saw.... I hate it when i need the dull one in my hole saw bucket.

Turned out pretty nice despite beating on it with a hammer to make the bends.

So I broke two things getting the old stuff apart... The old push button starter switch is no more. So a new one is on order, but in the mean time, the ignition key still starts the car.

But worse was when I went to turn the other battery cutoff switch in the engine bay and the handle broke off in my hand. That was a sinking feeling.

Fortunately those are replaceable keys and I could buy a new switch that came with two new red keys at the parts store.

So the car runs again!

So this weekend was the big one! Tech inspection for a new logbook for the 944 on Thursday, my competition license school on Friday, and running in the very first road race ever held at the newly-built Dominion Raceway in Thornburg, Virginia on Saturday. Sunday was another great race with everyone picking up several seconds as we all were learning the faster lines.

I also dynoed and weighed the car, which was interesting and inspiring.

So much to write. So many pics and video to review. Stay tuned!

You'll need to log in to post.