TimM

Reader

8/23/21 4:52 a.m.

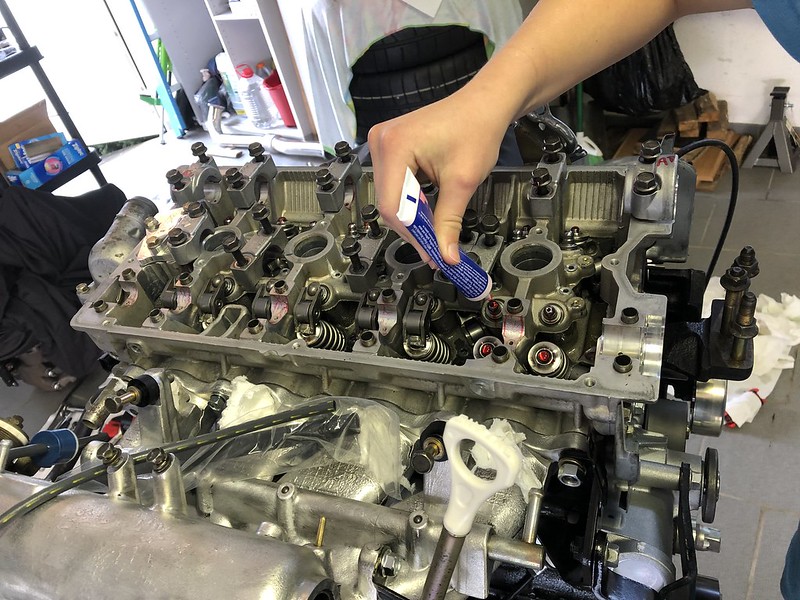

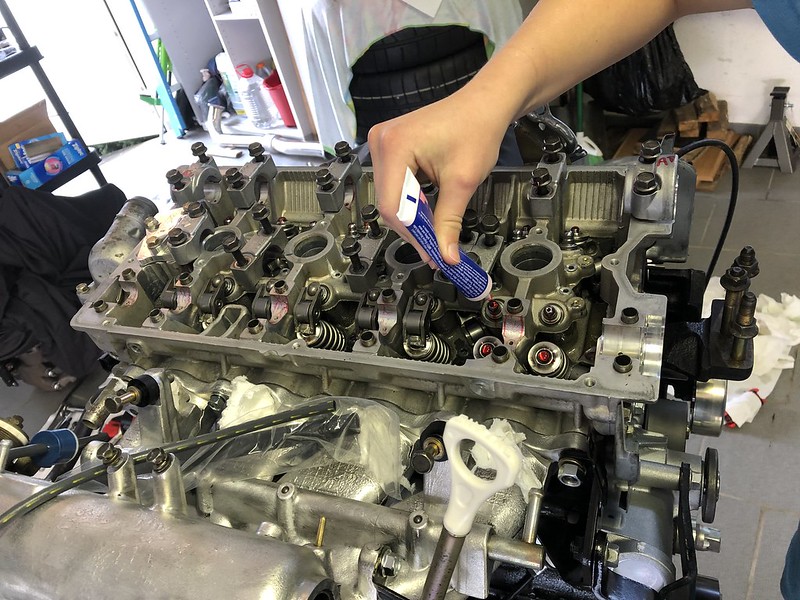

Pulled the cams to allow us to turn the engine over during prelube...had to enlist assistant #2 for a spell to get this moving:

We also pumped up the GSC 'No Tick' hydraulic lash adjusters (lifters)...that was mess and fingers sore after using a fine rod to push the plunger until air bubbles stopped...all while submerged in engine oil (no images - too messy).

In goes the 'flushing' oil:

Assistant to man the drill:

Took a bit to figure out if all is well...we were turning the drill too slowly...once we maxed the rpm, Old Faithful resulted! (We had also removed the OEM oil pressure sensor in hopes to remove any 'debris' on the initial prelube...it was reinstalled to fully prelube the engine while we turned the crank).

It was actually a good example of what interesting forces happen inside an engine and the engineering behind it. The slow pump rpm resulted in no oil movement...but once we hit a certain point, significant oil pressure/flow was created. And the force the oil came out the engine was quite impressive!

Cams reinstalled with all new rockers (not inexpensive, but if it builds a bit of reliability and quiet operation...) and torqued:

Careful...only 20 NMs!

How old is your daughter?

What kind of teaching process are you using with her?

Looking at different ways to help mine learn as the one ive been trying is only moderately successful.

TimM

Reader

8/24/21 8:29 p.m.

The assistant is a year or two shy of driving age so some challenges of showing satisfaction of the end result. But we built a LS M3 for Assistant #1 at the same age and he seems to have 'gotten it' as time goes on (just got his driving permit).

I tend to go with "regular quizzes about previous lectures" and the threat of taking the phone / solitaire away depending on her performance. ;-) She can name all the sensors and major components on the engine now.

Seriously, usually it ends up telling stories of how I did it wrong on previous projects and why we are doing it this way this time. Being foreign to the 4G63 makes it a bit uncomfortable, but I try to prepare myself before she enters the classroom area (garage). Small chunks works best. This takes 10 times as long, but this syncs up with the missing parts we keep uncovering as we assemble things (each with 3 weeks delay).

I've also mentioned that she will be the coolest 'boy' in the parking lot with a RHD Evo...so she better be able to not only name what cams are within, but also be able to drive to uphold the Evo's reputation - no posers here!

She hasn't complained and still says thank you at the end of the lesson...think we are doing ok.

TimM

Reader

8/29/21 1:44 p.m.

Set the timing on the camshafts...hopefully we did this correctly!

Intake cam mark:

Exhaust cam mark:

Crank mark:

Hydraulic tensioner setting...grenade pin slides freely in and out:

Does this look close enough?

In reply to TimM :

I think so, it's a little tough to tell the crank pulley with it being blurry, but honestly I don't see how it could be off.

TimM

Reader

9/3/21 3:14 p.m.

Pete: Appreciate the back up. We ended up doing it a couple of times and hit both extremes...settled for very nearly the same as previous. We think we are in the ballpark!

Little body work:

Pulled the front bumper...10 bolts/clips and off. Nice storage, eh?:

Cleaning the oil cooler areas...looks original (maybe not the horns):

Pulled the oil cooler...been exposed to elements for 6 years...look for an aftermarket replacement. Quite a light install actually:

New set of heater hoses...Mitsu sells as a kit - quite reasonable. Likely the high quality OEM rubber was good for another 20 years though:

Little driveline work:

New transfer case o-rings...big and small:

And a little engine work...wrapping the assembly up...

Assistant mesmerized at the valvetrain as she turns the engine over for the first time...

Once satisfied...pulled the hydraulic tensioner's grenade pin:

On to torqueing bolts - exhaust...figured afterward that pulling the heat shield provides nearly full access!:

We then realized we may not have torqued the cam timing belt adjustable pulley...so off cam the front cam drive once again...and messing up the belt tensioning...lots to learn!

TimM

Reader

9/6/21 3:32 p.m.

Some real progress!

More new vacuum manifolding:

Some metal reworking after dad demonstrated how soft aluminum will dent on the cam sensor housing if dropped (ack!)...assistant was happy to put the Dremel to it:

And install...final major component along with the AIR system tubing:

And a few bolts/covers to produce a complete powerplant:

Worked out the borrowed hoist and connecting apparatus without damaging the freshly coated valve cover (lucky!)...and installed the Cusco/Exedy two disc clutch - looks usable and light - 12 pound flywheel:

Friend also lent me a scale...119 kgs (262 pounds) for a near fully dressed 4G63 bullet (intake to turbo with alternator) - nice for ~400 CHP capability:

Big step:

And IN!:

Trans/transfer case install, fuel pump replacement, and awaiting the Russ Fellows exhaust to deliver...several other bits and pieces too...nonetheless, big stress reduction!

84FSP

UltraDork

9/6/21 6:55 p.m.

Looking good! Should be fun.

TimM

Reader

9/8/21 3:35 p.m.

It has been a great ride thus far and it hasn't even moved!

Crossing our fingers on the first start...but we have a ways to go...and more nuts and bolts to order...unfinished projects!

Definitely a great thread to read (from the beginning). Wish I could get my kids more interested.

TimM

Reader

9/10/21 1:49 p.m.

Thanks for the comment and glad it was a decent read. Looking forward to some return on investment (coming to life!)

TimM

Reader

9/11/21 4:13 p.m.

We continue to analyze all the connections...most appear to fall into place once we begin - scavenger hunt in some cases...

Few minutes today to install a new front badge:

Complete!:

And used an entire roll of paper towels to work on this:

Probably not worth is, but clean is more enjoyable...

TimM

Reader

9/12/21 2:23 p.m.

Not much improvement, but I feel better. Installing a new throwout bearing (the new fork lacked a bushing - oops):

Popped in the refreshed OEM injectors (we hope they will be too small!):

Some young lady fun...jeez - stay on task!:

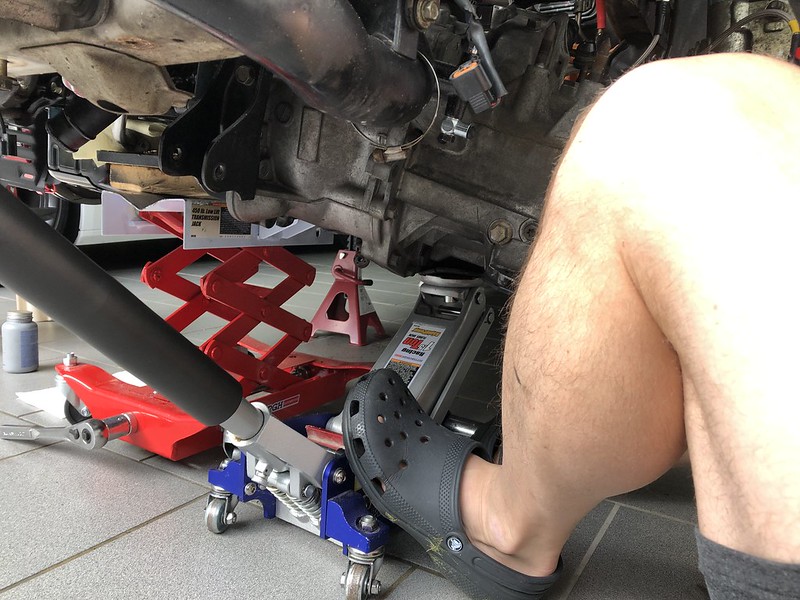

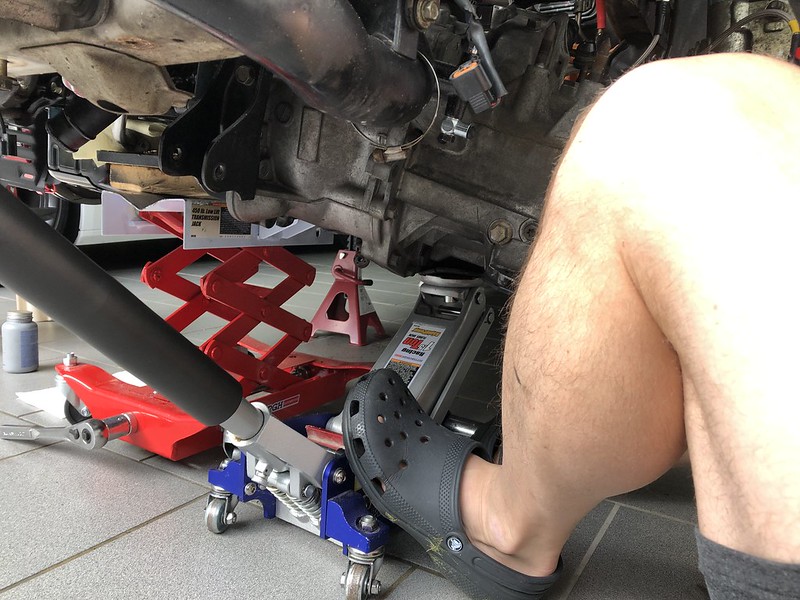

Back to the trans...on the move - balanced on a floor jack...precariously:

And Installed...hairy leg is mine...she was a bit too fragile for this part - served as eyes for the block to bellhousing alignment. Once we realized the idler pulley and belt tensioner should be removed to allow the motor to drop angle further - it all fit together...with some muscle:

Positive progressive!

MARF

New Reader

9/12/21 6:55 p.m.

Just read through your progress and must say I'm impressed. You're doing something amazing with your daughter

TimM

Reader

9/17/21 2:54 p.m.

MARF: Appreciate the comment...it will be even more amazing when the powerplant comes to life! We can only cross our fingers...expect to make considerable progress tomorrow...but lacking a few bits still...including the exhaust.

TimM

Reader

9/18/21 2:43 p.m.

Good 8 hours in the garage today...finally!

Idler and belt tensioner reinstalled:

Starter installed:

New slave installed...after working the clutch fork to engage the clutch collar successfully! Then bled all the black fluid out - first time I've gotten to work the pedal while someone else turns the bleeder - nice! And big news is we have full clutch movement - little concerned over the twin disk install:

Then to the intercooler pull and rinse out of debris and in this case quite a bit of oily residue which I would expect is normal:

Simple Green to the rescue! Rinsed several times...:

Drying setup...that hairdryer has many garage hours on it!:

Drained the transmission...hadn't been serviced recently - the rather impressive drain plug magnet contained an impressive amount of debris:

Assistant went about refilling the box with nearly 2 quarts of fluid until she mentioned it seemed to be draining out another hole in the transmission! Well, guess we should wait to refill until the transfer case is install - appear to share some fluid pathways...oops.

We did arrange the shifter cables appropriately and popped them on (missing the hardware though!)...and we have gears! Little lady couldn't wait to hop in and do some gear jamming! Shifter seems a ok...at least statically.

Much time was used finding the correct or close enough bolt from the stash. Couple of cases we resorted in trimming a few threads - interesting she loves the Dremel...so did I as a kid (and adult)!:

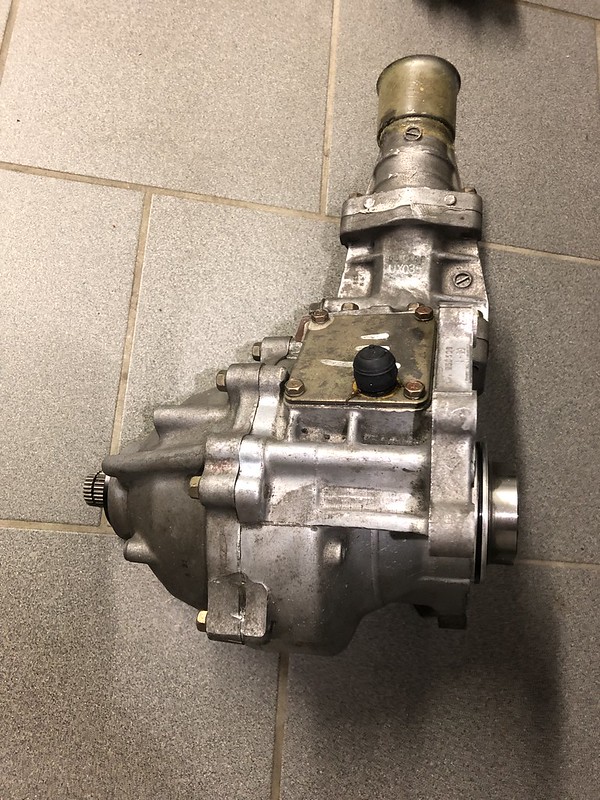

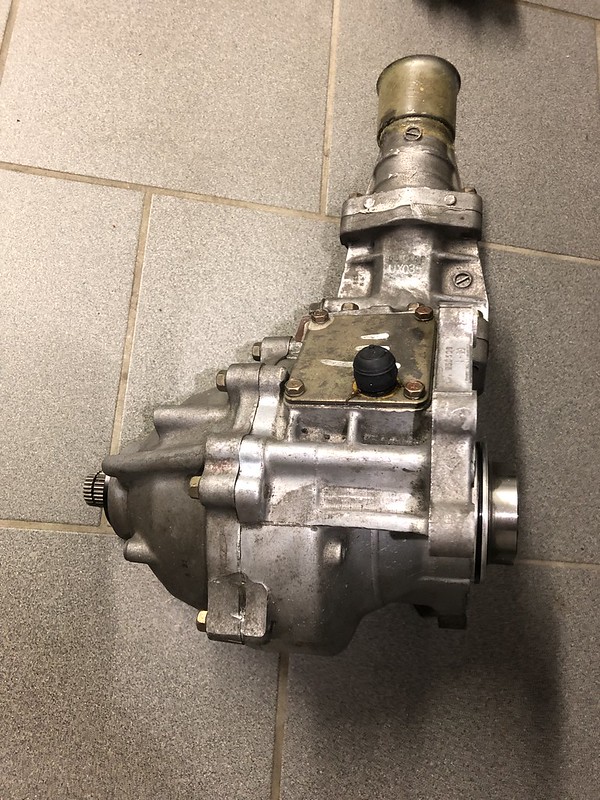

Transfer case weigh in...59.6 pounds:

Fun shot:

TimM

Reader

9/19/21 5:53 a.m.

Shot of the inbound exhaust:

Full 3 inch, 200 cell cat, and extra quiet build (longer muffler/resonator).

In reply to TimM :

I think you're going to love that exhaust.

TimM

Reader

9/26/21 2:20 p.m.

Pete: I just hope it doesn't wake up half the village on cold start!

Second order of 'T' adapter fittings arrived - this time German made vice the Speedway Motors in Nebraska (Chinese!). The first attempt did not have enough taper on the threads to allow even starting thread engagement. Hopefully these are acceptable as these seem to be geared toward hot water systems...SS metal construction:

The install above the transfer case (not yet installed) into the back of the block - the OEM sensor and the Autometer sender:

And the 60 pound transfer case...bench lifted with little fanfare as it quickly guided its way home and bolts easily accessed. 5 of the 7 are new as they were nowhere to be found - glad Mitsubushi parts are plentiful!:

In reply to TimM :

My exhaust is 3" catless with a straight-through muffler about the same size as yours. It's loud enough I wouldn't start it past around 8pm at night, but there are pickup trucks in the neighborhood that are louder.

TimM

Reader

9/29/21 2:33 p.m.

Pete: I sure don't want to irritate the German neighbors...I'm an early riser so...we will see. Supposedly this builder does wonders with track day noise limits in UK and although I didn't get the muffler - 'CAT'...crossing my fingers. Thanks for the comments.

Shots of the just arrived custom UK exhaust...full 3 inch with CAT. Weigh in is 32 pounds complete. The previous Fujitsubo setup was over 50 pounds...

CAT:

Good sized tip:

We also received a set of 1050 cc ID injectors...hoping to surpass the current OEM injectors...hoping:

We have another Saturday dedicated to the 3d puzzle...making headway!

TimM

Reader

10/2/21 2:35 p.m.

Productive day!

Front axles installed...and wheel bearings torqued to 177 NM minimum:

Gearbox refill on-going...this time it didn't leak out as fast as she put it in thanks to all parts actually installed this time!

Coolant sensor harness reset due to Evo 5 harness with an Evo 6 thermostat - no wire cutting though:

Finished product:

New cam gear cover due to chunk missing of the original...not to mention lacking any 'seals':

Battery relocation platform install:

Little bit of soldering - she quite enjoyed the liquid metal:

End result:

Polishing the new ground connection - really enjoys the Dremel although that wire wheel left its mark - she now wears gloves...:

New airbox intake tube with metal Evo 9 recirculation valve - clean!

Even pulled this line to replace two semi flattened o-rings - hope that solves the static leak:

The list of tasks seems to grow!

Does anyone know where this goes?

End of day:

In reply to TimM :

I can't really tell the orientation of those 2 lines. Are they running down over the transmission? Do you know where the other end goes to?

TimM

Reader

10/3/21 1:06 p.m.

Pete: Apologies - poor references. Few more:

Believe that hose comes from the OEM boost control solenoid and doesn't go far - another shot:

Not sure where this goes - charcoal canister barb on the bottom:

And another - the valve cover breather may connect to this one...doesn't quite reach, but aftermarket is like that...:

Last one:

Maybe they all connect to each other!

Had a short spell today...family consumed most of the day:

Project came with a seemingly good aluminum radiator...quite robust too! Little extra room to install:

Temp installed the gauge package...still need connections - hate to drill any holes in the auto, but this seems low impact and when closed is out of sight - mainly these are for tuning and/or issues:

Now they are invisible:

Current shot - looking pretty good!

In reply to TimM :

Looking great! All the emissions stuff on mine is long gone, but I'll try to remember to check the FSM & see if it has a diagram that may be helpful.