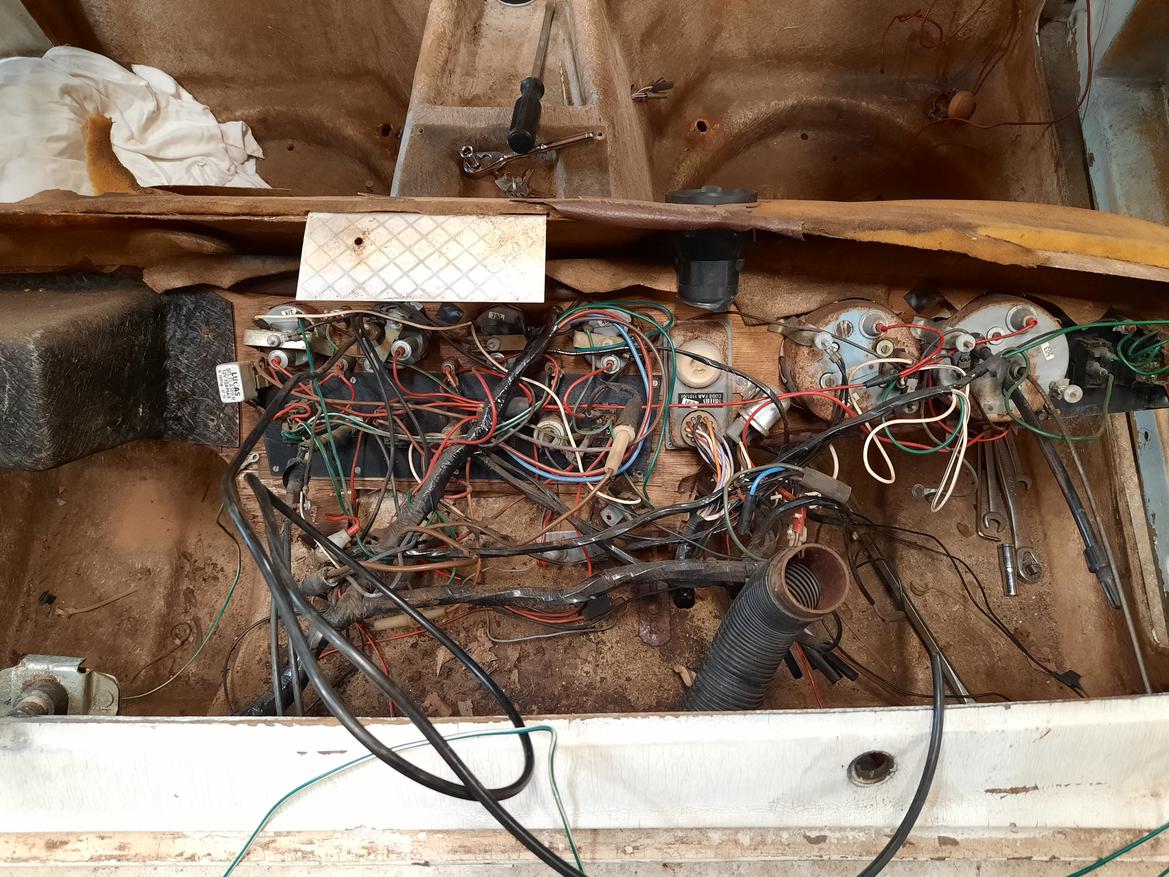

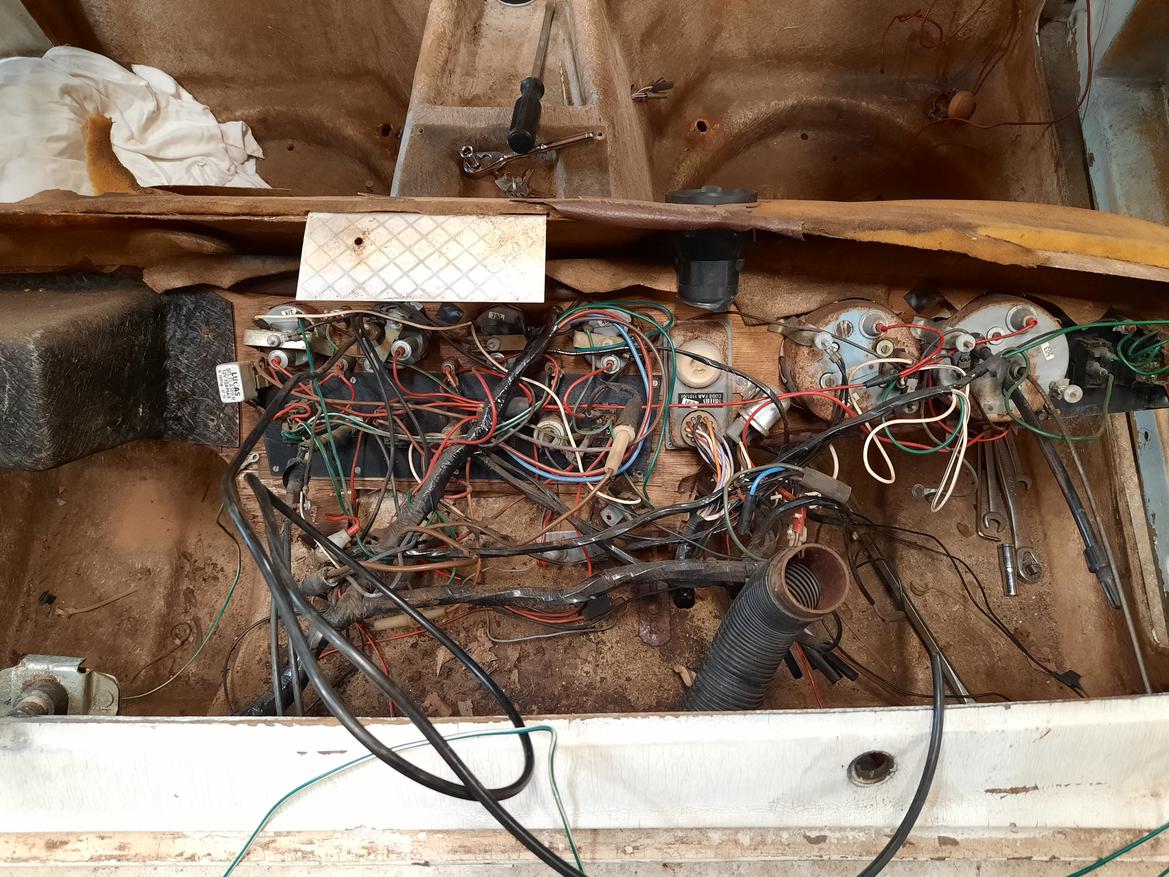

It has been a while since the last update, but things have been going on with the TVR... or coming off, rather. While waiting on the engine build I figured I should continue stripping the body. Getting the peddle box out meant getting the brake booster and brake/clutch cylinders out of the way, so I continued with that area and tried to get the dashboard out without too much destruction. Not happening... the wood at the bottom was pretty much rotted away, but the brackets holding it onto the tunnel were solid, as in rusted solid. Had to cut the bolts off. Then I tried to separate the dash (wood) from the crash pad (fiberglass). That didn't seem to want to work, so I figured out that the entire dash was held in by 3 bolts, one on each side and one in the middle coming through the firewall (other than those into the tunnel). An oscillating hacksaw got them out, and the dash structure was free! But that just exposed this...

A lot more wiring than under a Triumph TR3 dash! I know a lot of that mess will not be staying, and I intend to rewire anyway, so I cut off the fat harness going through the firewall and just pulled it all out of there. The interior got much less cluttered with that gone. Then the wiper motor and assembly came out, and the hood latches were removed.

That left the heater chamber ("plenum"?), which is a fiberglass panel screwed into the firewall and sealed with a fat bead of putty. TVR used a bunch of fairly small flat-head screws for this, and they were hard to remove without shredding the heads. But, with that out of the way the engine bay is pretty much cleaned out for bodywork and painting!

You can still see the battery platform in that photo, but that's gone now. Also pulled the panels from the passenger door. Moving to the rear of the car, the only remaining wiring is to the tail lights and gas tank. The tail light assemblies seem to be in pretty good nick, but once again the nuts holding them in place were rusted and most bolts just broke off. Still, the lights are off and the remaining harness was yanked free.

Looks a little naked now. The piles of parts are getting taller. Boxes of wiring and lights, gauges to be rebuilt, interior panels to recover, starting to overwhelm the build.

My next concerns involve how far I need to go into the doors. The mechanisms are all functional, but very stiff... I know they should come out for a good cleaning and lubrication, but I'm afraid that I could easily get in over my head. The window-frame and hardware seems very corroded, and I suspect I'll be drilling out a lot of screws and rivets. I'm assuming it's not really any different than with a steel door in that one still has to work through the little "windows" cut into the inner doorskin. Sounds like a job that might involve the experience and know-how of friend and mentor Michael!