Man, I'm getting giddy. I've also picked up the block and crank from the local shop too. I'll be giving them a good look-over next day or two. The current motor and clutch are both starting to give me some signs that they're coming due. I'm just hoping I can keep them both going for the remainder of this autocross season. Being ready for one-lap in time is going to be a crunch after all it seems. In current condition I don't consider the car up to the task for doing any track duty.

In the meantime, I've been getting a bit distracted for my offseason practice. My little business had a great Labor Day sale too, so I've got two more monitors on the way.

A bit further.......

What are the short block specs? Pistons? Deck?

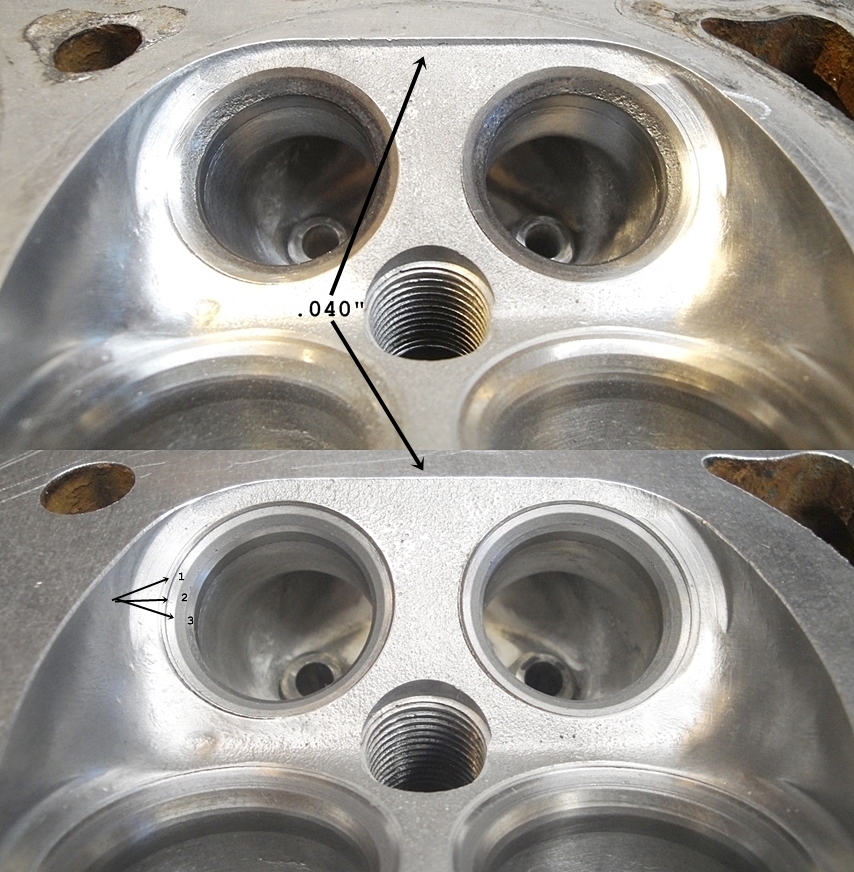

I'm thinking of taking a big slice (.040") from the head... get the chambers down to about 34-33 cc (currently @ about 37) this will raise compression "substantially", but it will require adjustment of the cams to get accurate cam timing.......

Pistons will be standard bore, but I figured I'd wait until I knew the head dimensions before choosing exactly. And without knowing exact pistons, I can't give a measured deck height yet either.

I'd say go with the big slice.

I'll just make sure to measure the actual deck height of the piston at the time of bottom end assembly and use an appropriate thickness head gasket. This way I can also match the piston compression and such to the head too.

The bad news for this update, is that I had to cancel my trip to the Waumandee hill climb. All the other engineers at work, plus my boss, will be out over that weekend. So I can't take the time off. That sucks, but what can you do. And only one more autocross left this season too, which also makes me sad. Otherwise, this months event was a much more horsepower driven course, and I suffered for it. Too much time spent with my foot planted on the floor and wishing for more power. I still had a decent showing for placement, but not as good as I would have liked. The solution to that is in progress of course. Parts are slowly coming in, and for right now funding is on track to get the engine done over this winter.

There are a few new areas I'm also going to start working on, since this car is too far down the path and will never be 'original' again anyway. One is that it's time to start grinding off un-used brackets wherever I can find them. Things like the spare tire mount in the frunk, original battery tray, stuff like that. I'm still undecided if I want to re-harness the EFI system for Megasquirt or keep the factory harness and adapt it. I keep procrastinating on that change because the stock ECU is working fine and I don't want to screw things up right now.

Exhaust at some point I really want to take care of too. I'm just tired of the monster muffler under the back-end. Everything from the engine-back is an aerodynamic mess on the underside. I'd really like to start looking at underside aero over the winter too if possible. That and something to eliminate all the drag from the huge-ass mirrors. I've got some ideas on that, but I really want to get the car up in the air so I can look at things and come up with a comprehensive plan. If I just add things here and there, god only knows what the result will be.

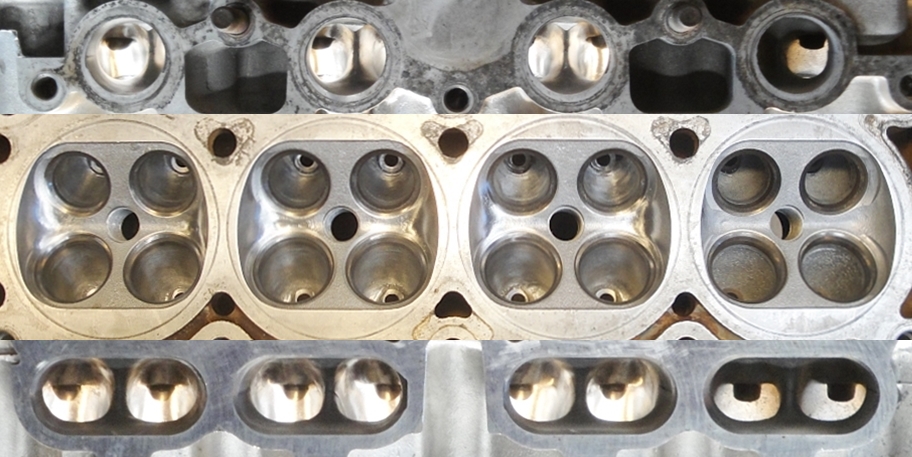

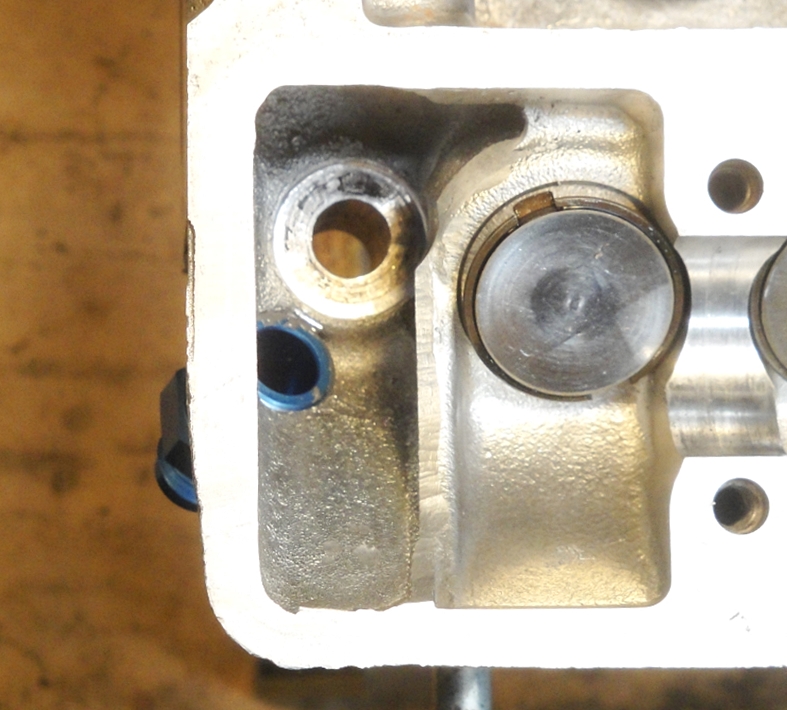

oldeskewltoy said:those exhaust seats are just horrible....

Not any more... and you can now see the "chunk" taken from the head

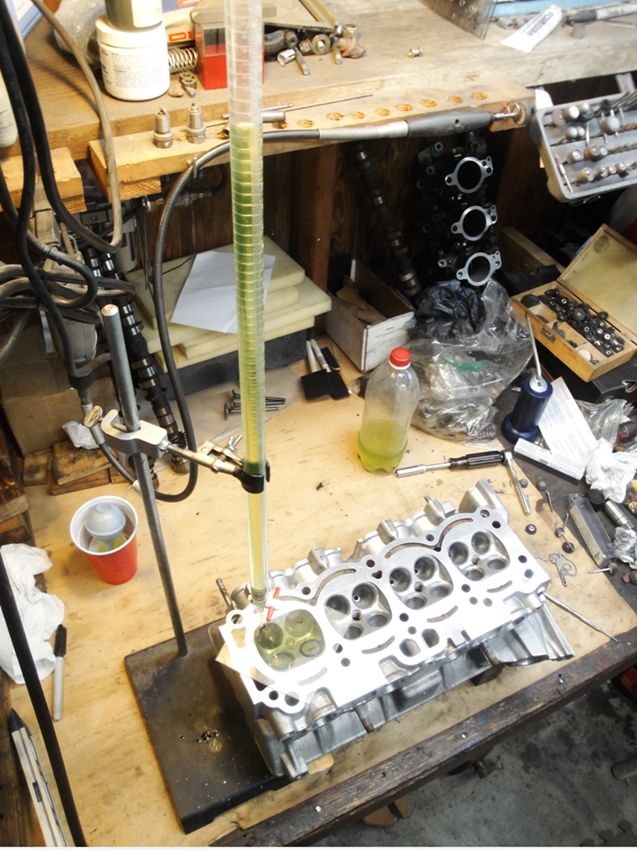

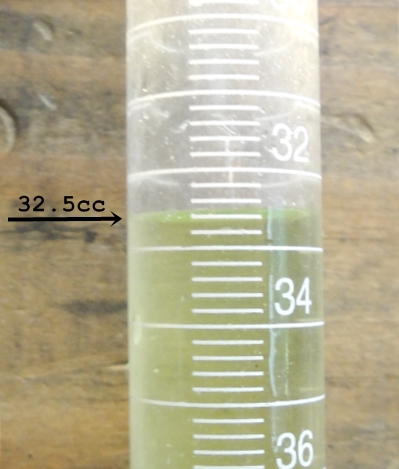

stock 4AG chamber comes in @ 36cc, this chamber now sits at a "svelte" 32,5cc (to use for CR calculations)

Going to be exciting assembling this lump pretty soon here. Time to start sorting out piston selection now that I have the chamber volume, always fun looking at charts to see the actual dome volumes.

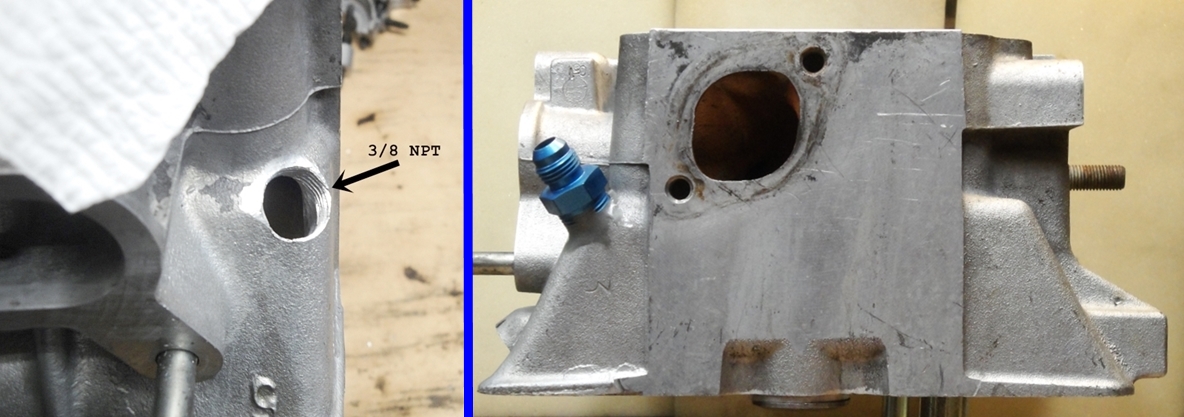

Didn't forget my oil drainback in there, did you?

-Hans

hhaase said:Going to be exciting assembling this lump pretty soon here. Time to start sorting out piston selection now that I have the chamber volume, always fun looking at charts to see the actual dome volumes.

Didn't forget my oil drainback in there, did you?

-Hans

I hadn't seen the request... but adding it was nothing that caused a delay... the delay is waiting on the ordered shims to set valve clearances......

a different perspective.....

This is an oiling modification. It is principally designed for use in longitudinal applications, to minimize engine "issues" during long left hand sweepers. The 4AGE largeport, and 20V engine have only 2 oil drains from the head - both on the exhaust side of the engine(D/S in FR application) The largeport issues: a) head packs with oil, excess is forced out the breather into the engine - blue cloud, or filling of oil catch can, OR, b) head packs with oil emptying sump, causing rod bearing failure. The extra drain in the back of the head minimizes any oiling issues.

Hmmmm, I really do like this location better than what I originally pictured, which was more akin to the smallport factory spot. This location will definitely drain better, and will work real nice when I make the change to a dry sump down the road.

Just a week and a half till the final autocross of the year, and then it's going to be final decision time for a few things, one of which is if I'm going to push one-lap out for one more year. It all depends on how well I can get the new engine sorted in time, and if I can get my track instruction taken care of in time too.

-Hans

hhaase said:Hmmmm, I really do like this location better than what I originally pictured, which was more akin to the smallport factory spot. This location will definitely drain better, and will work real nice when I make the change to a dry sump down the road.

Just a week and a half till the final autocross of the year, and then it's going to be final decision time for a few things, one of which is if I'm going to push one-lap out for one more year. It all depends on how well I can get the new engine sorted in time, and if I can get my track instruction taken care of in time too.

-Hans

I wouldn't rush your track instruction. Brock requires 2 days of "HPDE with in-class instruction" as a minimum. A general rule of thumb that I use now is 6 days and being signed off solo.

OneLap is different than normal HPDE in that you are much more likely to "see the red mist" at OneLap, or have those around you see it and then have to deal with either situation. And unlike autocross, we will end up someplace that has big speed, and the potential for big consequences.

"You're going into the forest, you better have your wits about you" or "any aircraft accident is the result of not one wrong decision, but many in a row that overwhelm any good decisions"

Judge the risk, make good decisions

In reply to sleepyhead :

Completely agreed, and I've basically already decided to push things out another year. It's more a case of me not being ready mentally to tell everybody else. So let's keep it as a secret for now, kay? Right now I don't feel things are up to the level they need to be. I have a persistent oil leak that only a full engine rebuild will solve, the clutch may be showing signs of being worn out soon, and I have concerns over the front end handling at speed. If I had a big budget and plenty of free time I could easily get all of this done by May. But I don't have the resources right now to say with confidence that I can get it all done.

Though having another year gets me back into day-dreaming mode. I think after next weekend I'll be tearing out the stock ECU and harness and start the MS conversion. I need to do that eventually anyway. But if I do it now I can also re-lay the harness in a way that'll be easier to drop the engine when the time comes. Plus I can get all the risky stuff in the base tune taken care of with an engine that's not mission critical.

-Hans

hhaase said:But if I do it now I can also re-lay the harness in a way that'll be easier to drop the engine when the time comes. Plus I can get all the risky stuff in the base tune taken care of with an engine that's not mission critical.

-Hans

use a military grade connector and make the harness 2 piece! Then you just twist the connector and drop the engine

In reply to oldeskewltoy :

That's the plan. Though I prefer Metri-pack by a long shot. Either 150 or 280 series depending on the amperage.

Arrived Saturday, but I spent most of the weekend ripping a big hole in my garage ceiling to fix a leaky bathtub. That and had a big reseller order of pinball stuff I had to finish up. So all I've been able to do so far is make sure it's not damaged.

That and cloudy and drizzling for 4 days straight, so no photo opportunities for the car.

-Hans

I have a lot to report on the end of the autocross season, nearly all good things, a couple minor negatives that I'm not worried about. But I need to get a bunch of video and photos downloaded, edited, uploaded, and e-mailed. So I'll do that later.

More good news though on the engine front. Found the perfect pistons at a great price. Gen-you-wine Toyota small-port 4AGZE. The dome height will get me right where I want as far as compression ratio after calculating with the actual chamber dimensions. They're forged and coated from the factory. I got the correct 'mark' size to fit the block tolerances (#2). And they're already cut for the oil squirters in the block. New in the box for $230 shipped.

Really starting to come together finally.

Huh. I thought I had 5th. Looks like I miscounted somehow. I had 4th for the year, and only missed 3rd by 3 points.

Gotta love that!

Edit:

Also, add some ARP rod-bolts into the incoming pile. Once those and the pistons get here I can measure to confirm the ring sizes, and get the rods down to the machine shop to get them prepped for assembly.

It'll actually be a very interesting experiment to see the dyno numbers on this engine in NA trim. The compression ratio will come out to almost right at 9.5:1 with the high-comp 4AGZE pistons and this chamber size.. I'm also using the stock cams as well. So essentially it'll be a stock motor prior to adding the turbo. Which also means that the only significant change from stock will be all the cylinder head work.

Thus, any HP over the factory numbers will be attributable to the head work and chamber geometry differences.

-Hans

In reply to hhaase :

your cam timing will be off by close to 4 degrees retarded... so stock cams go from 111 degree center line to 107. the results will be power peak should move higher - be about 6800-6900 rpm - stock cams(stock cam timing) peak @ 6600-6700.

Retarding

You'll need to log in to post.