In reply to Pete Gossett :

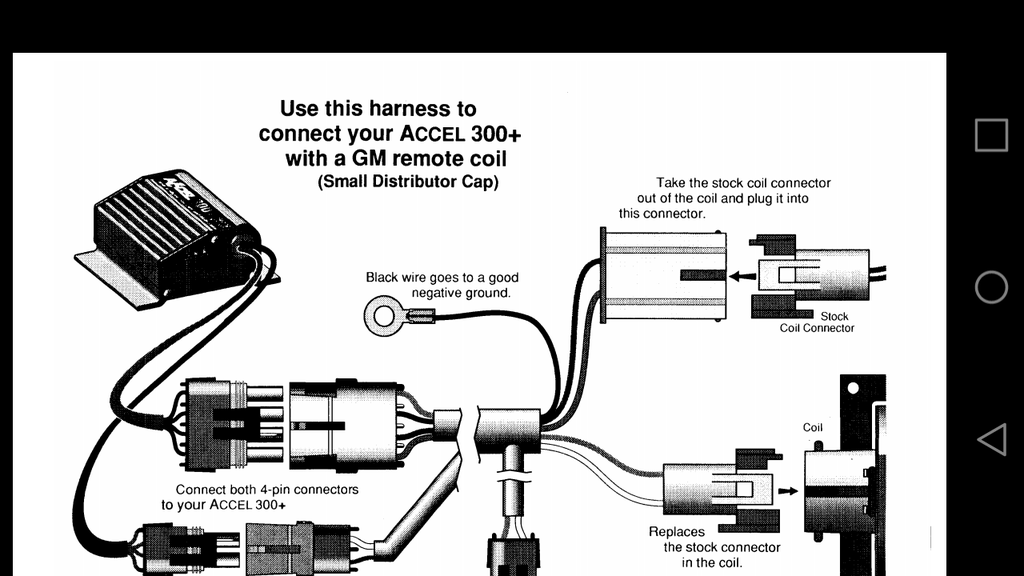

Stock cap won't fit behind the hsr plenum. Have to switch to a small cap design with a remote coil.

School shop class put it in almost two years ago, and I can't get ahold of the teacher...summer and all.

In reply to Pete Gossett :

Stock cap won't fit behind the hsr plenum. Have to switch to a small cap design with a remote coil.

School shop class put it in almost two years ago, and I can't get ahold of the teacher...summer and all.

In reply to Pete Gossett :

[URL=http://s1156.photobucket.com/user/rbates74/media/Screenshot_2018-07-23-18-40-53_zpsqdoao6ds.png.html] [/URL]

[/URL]

It's a purpose made harness. Top right of the picture is the relevant plug.

I have gone through the parts and found some instructions, some barbed fittings and a pigtail for a stock small cap coil.

Only problem is, I am not sure where to wire the pigtail in at?

What does the stock remote coil conector connect to?

I bought a coil, coil mount and pigtails for $16.

Got it wired up. And started... Sort of.

It ran a few times for 15 to 30 seconds at a time, but it was in slow motion. (I could read the letters on the serpentine belt as it went around) then it would backfire and die.

Fuel pressure would only go up to 10...

Pump is a walboro 255, only about 2 years old. Changed the filters at the same time.

I pulled the pump to check for contaminants in the tank and to make sure the in tank filter was not plugged. All kosher.

Fuel pump comes on but pressure doesn't seem to build. No fuel in the vacuum line.

Pressure regulator instructions say it comes pre set at 43 psi, any chance it could be set low?

I will pull and inspect/replace the inline filter on Sunday, but I really doubt that is the issue.

In reply to AngryCorvair :

Every thing looked ok, but I wasn't specifically looking for that.

I will add that to my list of things to double check, though I don't consider it likely.

But really I am left with only unlikly issues. Bad pump and or filter with only about 1k miles on them, or kirban fuel regulator set at 10 psi from the factory.

In reply to Crazier :

Can you pinch the return line at some point along its run & see if it causes fuel pressure to rise?

In reply to Pete Gossett :

Good question, i think I am going to the hydraulic store in the morning, if I wake up on time. To buy a couple JIC end caps (jic is the same as AN but a little heavier and a LOT cheaper) to block off the AN lines and see if the pressure builds before I do anything else.

I am starting to wonder about the fuel relay as well.

Think there would be any harm in running a jumper wire from the battery to the hot wire on the pump?

I know before the pump would kick on when the key was turned and then right back off, maybe it doesn't stay on long enough to build pressure?

In reply to Crazier :

Also check the fuel relay plug, it’s basically a wear item on a C4. I used a broken piece of hair comb & a zip tie to hold the terminals fully seated onto the relay.

With the return line plugged it jumps instantly to 60+ psi when the keys is on. And seems to be slowly going down over the last 15 minutes down to 30 psi.

This indicates that the fuel pressure regulator is not building pressure? Causing the 10 psi problem when it isn't plugged.

And that there is anouther problem like a leaky line or bad injector causing the slow loss of pressure?

Bad o ring on the inlet line Saginaw valve. Luckily I had one on hand.

With the return line blocked it still jumps to 60+ instantly. I timed the bleed down after wards and it took over 6 minutes to go from 50 psi to 40 psi. Less than 2 psi drop per minute.

May still be a very small leak, but not enough to make a problem starting.

Now to hook the return line back up and mess with the regulator.

Well. My fuel line set up is Holley spec. Everyone rotates the FPR because of clearance issues with the distributor.

I can't adjust the fuel pressure with the fuel rail installed.

So my plan is, install a set of injectors into a spare intake, set that into the engine bay and install the fuel rails on to the spare intake. Disconnect the distributor and then have some one crank the car over while I adjust the regulator.

Then reinstall it all. For the 19th time.

I tried it a little today, just by holding the injectors in place with a few extra hands, but we couldn't keep it stable we did manage to get it to hold 30 psi for a few brief moments.

Think the plan will work?

My other option is to spend a bunch of cash to make a secondary fuel line set up, use it to set the pressure, and then swap back to the old set up for the race.

As a bonus... I think this would also detect leaky injectors if there happen to be any.

Note. New in the box parts may have been taken out and played with, at least that is my theory on what happened here. The regulator holds pressure, but it was turned all the way out.

On a stock car, the fuel pump cycles once when you turn the key on, then runs again after the oil pressure comes up and closes the oil pressure SWITCH. (As opposed to the sender for the gauges)

That switch might be broken or disconnected.

You would get fuel enough to run for a few seconds, but the pressure would fall off quickly and the car would die.

a_florida_man said:On a stock car, the fuel pump cycles once when you turn the key on, then runs again after the oil pressure comes up and closes the oil pressure SWITCH. (As opposed to the sender for the gauges)

That switch might be broken or disconnected.

You would get fuel enough to run for a few seconds, but the pressure would fall off quickly and the car would die.

And that switch should be just past the lower intake at the top of the block, just to the driver’s side and rearward from the distributor. It may screw into a “T”(of sorts) that also has the oil pressure gauge sending unit.

My last round of research said there were 3 ways the fuel pump could be energized.

That the third method was when the ecm detected an ignition pulse. That it would keep the pump on after the initial "key up" before the oil pressure kicked in. But maybe I got it wrong.

In reply to Crazier :

I’m not familiar with the circuitry of the later years, but in my 85 it was as simple as jumping 2 leads on the FP relay to make it run all the time. I wired it to a toggle switch so I could manually turn it off.

In reply to Pete Gossett :

Well, as it turns out I intended to have a hidden fuel cut off switch as a theft deterrent as the key is stuck in the ignition.

May end up killing two birds...

Using a dummy intake to set the fuel pressure worked. It now holds a steady 42 psi.

I used the "screwdriver stethoscope" trick to confirm that at least some of the injectors are pulsing when the ignition is cranked.

I doubled checked the settings on the 300+ box.

Still won't start.

So the plan for today is an inline spark plug test light, swapping in the jy coil rechecking all the connections, searching for any other missed conectors and possibly resetting the base timing.

Currently I have not found instructions specific enough for setting time.

Put the #1 cylinder at TDC. How do I determine TDC? After getting it to TDC I assume I point the distributor a certain way and also the rotor. How do I know where to set them?

Assuming I can figure out how to set the timing, then I will verify the firing order.

And if it still won't start after that... Yeah, dynamite time!

I guess I have to test the ignition module as well. Does the module from the large cap fit in the small cap distributor?

In reply to Crazier :

To set TDC, pull the driver’s side valve cover & #1 spark plug. Put a ratchet or breaker bar on the crank bolt & turn it until both #1 valves are closed. Check #1 piston position to make sure it’s at the top too. At that point you should be able to double-check the timing mark on the crank pulley vs the timing tab. They should be very close to aligned, rotate the crank slightly to get them into alignment.

Note: this is presuming you have the stock pulley & timing cover/tab. GM used at least 3-different ones over the years, so there’s a possibly they won’t line up. Hopefully not...

The distributor timing is pretty easy - with the #1 piston at TDC, whatever terminal the rotor is pointing toward is now #1. Run the remaining plug wires in the correct sequence.

[URL=http://s1156.photobucket.com/user/rbates74/media/20180729_101624_zpsutswg9d4.jpg.html] [/URL]

[/URL]

Found this one trapped between the distributor and the fire wall. Anyone know what it is?

[URL=http://s1156.photobucket.com/user/rbates74/media/20180729_105319_zps2ggx1yp9.jpg.html] [/URL]

[/URL]

This did not look right to me... All of them were like that, but that one was probably the worst. Cleaned them off and about to try again.

The oil pressure sending unit seems important... I suppose that should be connected?

[URL=http://s1156.photobucket.com/user/rbates74/media/20180729_112159_zpsowkqtsla.jpg.html] [/URL]

[/URL]

[URL=http://s1156.photobucket.com/user/rbates74/media/20180729_112433_zpswgzl447l.jpg.html] [/URL]

[/URL]

[URL=http://s1156.photobucket.com/user/rbates74/media/20180729_112159_zpsowkqtsla.jpg.html] [/URL]

[/URL]

[URL=http://s1156.photobucket.com/user/rbates74/media/20180729_112529_zps4ciu7s3k.jpg.html] [/URL]

[/URL]

Can't figure out where it would connect.seems to be conections in all the ports.

It seems to be the single wire for the instrument panel? So it wouldn't prevent starting?

You'll need to log in to post.