Why shake your hand? because the energy had to go somewhere. When you pull it back, it stores energy. When you let go, it transfers it to the arrow. The dead weight at the tips of the bow slow down the limbs, meaning less can be transferred to the arrow. When the string slams tight, it usually takes some of that energy in the form of stretch, and releases the rest into the cartilage of your bow holding hand. This hurts after a while, and can lead to bow limbs and strings breaking.

On that note, never pull the string back and let go without an arrow. it's called "dry firing" and it means the bow limbs and string must absorb ALL of the energy stored in the bow. This, if you are lucky, can cause damage over time. If the bow is made without as much extra safety built in (likely making it a faster bow) it may just break outright. NEVER do it. ever. You wouldn't weld a plug into your shotgun barrel, load a blank, and fire, would you? Same kinda deal. The shotgun would have to absorb all of the energy, and something would likely break.

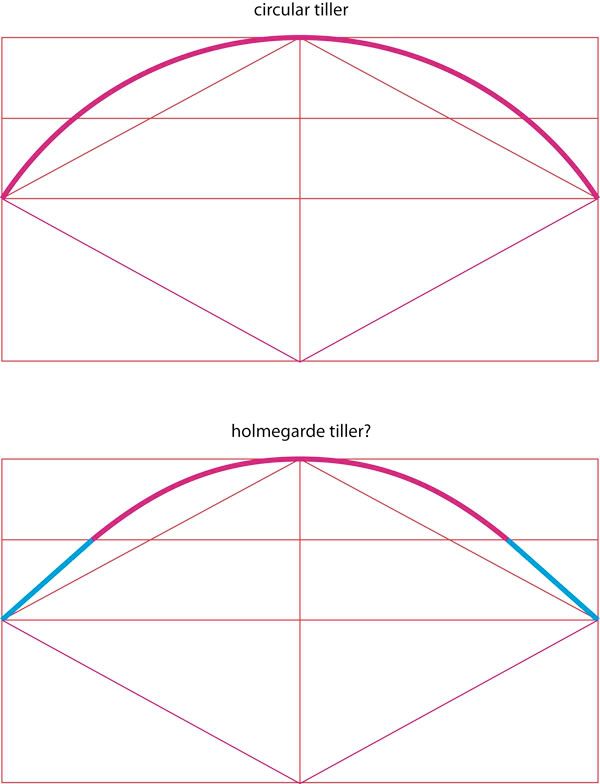

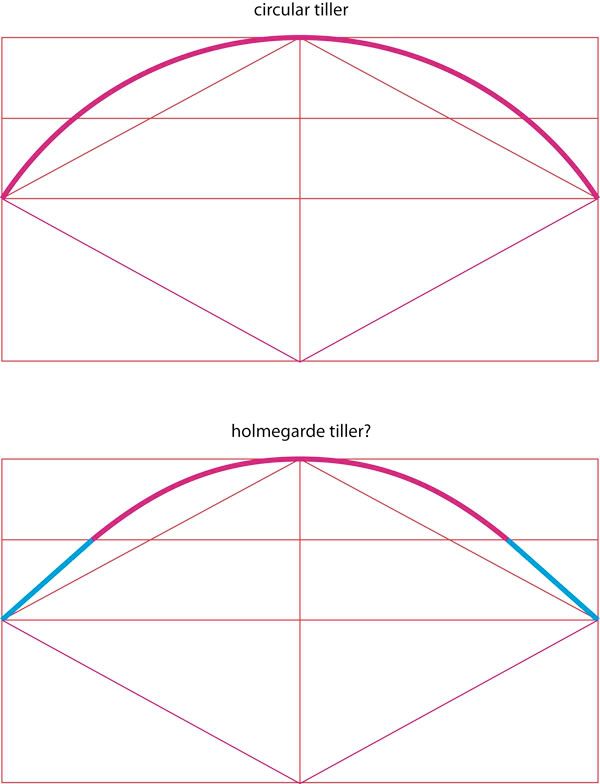

The best way to prevent this is to narrow the limbs as you get closer to the tips. This means there is less worthless wood weighing down the limbs, and with less bending resistance, the outer limbs will take on some of the bending stress. We want the whole bending portion of the limb to be doing work, and no extra weight slowing down the limbs. However, longbows can take multiple shapes. Some are extremely wide near the handle and the limbs narrow to a near point on the tips. They look like pyramids, hence the name "pyramid bow". These take on a circular bending shape, and generally have a stiff handle. English long bows bend through the handle, and generally take on a elliptical tiller (bend shape). This means they bend less in the handle, and more near the tips. This has many advantages, namely that bend near the tip bows don't move the whole limb back, meaning less energy will be spent moving limb weight forward. The power curve won't be as fat, though. Some longbows do bend a lot in the handle, and have long stiff tips that are extremely narrow. These stiff tips act like levers, which can make for fast bows, as well. This is called 'holmegarde tiller' in the photo below.

These shapes can all be made to high efficiency by different front view shapes. basically, if you see more bending, it needs to be wider there. If it isn't bending, make it narrower, but thick enough not to bend. That way, no one area will be stressed too much, and no unworking area will have dead weight. Dead weight matters more the farther out the limbs you go. The one I suggested on the first page would produce a fairly elliptical tiller, the other's are a bit harder to make. The bow i'm making for this build along is a bit more like the holmegarde tiller, but somewhat in between.

These shapes can all be made to high efficiency by different front view shapes. basically, if you see more bending, it needs to be wider there. If it isn't bending, make it narrower, but thick enough not to bend. That way, no one area will be stressed too much, and no unworking area will have dead weight. Dead weight matters more the farther out the limbs you go. The one I suggested on the first page would produce a fairly elliptical tiller, the other's are a bit harder to make. The bow i'm making for this build along is a bit more like the holmegarde tiller, but somewhat in between.

There's also a length consideration. Longer bows tend to have more power under the curve, but have a lot more mass. short bows have less mass, but tend to have less power under the curve. For the average person, the best balance for a long bow seems to be about 5 1/2 feet. 6 feet makes for a bit more safety. I like safety.

One accomplished bow maker/experimenter named Tim Baker had an idea for an 80" long bow. The thing has short bending limbs, which means less moving mass like a short bow, but a really long stiff center section that wouldn't bend (and therefore not store energy, and not contain mass to drain the energy). This means the bow holds more energy like a long bow. Put that together, and it makes for a really fast shooting $6 board. We took that idea and made a 72" oak bow that only draws 24" for my friend's fiance. It shoots very fast, despite being "too long" for the draw length.

Keep in mind, recurves open a whole host of other design considerations, but just ignore those. All you need to know is that recurves store more power, but don't tend to shoot faster at lower weights due to the increased tip mass unnecessary to make them stable. (to resist twisting)

Remember, the power is a useless factor when weight isn't considered. My van has FAR more power than my wife's G20, but the infinity has FAR less weight. It's also a stick, so it doesn't lose as much to an inefficient automatic transmission.

Those bowyers bible books use this example: What can hit a golf ball farther, a freight train or a golf club? The train stores FAR more kinetic energy, but the golf club moves faster, and can transfer more energy into the golf ball.

That's right, a parabola. It would bend like crazy in the handle, and bend less toward the tips. I don't know why, I'm an archaeologist, not a physicist. It's just what happens. This would result in a great amount of stress in the handle, and a lot of wood near the tips not doing much except weighing down the limbs. If the thing didn't break in the handle, it would shake the living crap out of your arm.

That's right, a parabola. It would bend like crazy in the handle, and bend less toward the tips. I don't know why, I'm an archaeologist, not a physicist. It's just what happens. This would result in a great amount of stress in the handle, and a lot of wood near the tips not doing much except weighing down the limbs. If the thing didn't break in the handle, it would shake the living crap out of your arm.  These shapes can all be made to high efficiency by different front view shapes. basically, if you see more bending, it needs to be wider there. If it isn't bending, make it narrower, but thick enough not to bend. That way, no one area will be stressed too much, and no unworking area will have dead weight. Dead weight matters more the farther out the limbs you go. The one I suggested on the first page would produce a fairly elliptical tiller, the other's are a bit harder to make. The bow i'm making for this build along is a bit more like the holmegarde tiller, but somewhat in between.

These shapes can all be made to high efficiency by different front view shapes. basically, if you see more bending, it needs to be wider there. If it isn't bending, make it narrower, but thick enough not to bend. That way, no one area will be stressed too much, and no unworking area will have dead weight. Dead weight matters more the farther out the limbs you go. The one I suggested on the first page would produce a fairly elliptical tiller, the other's are a bit harder to make. The bow i'm making for this build along is a bit more like the holmegarde tiller, but somewhat in between.