Not a lot of progress made this past week. Unfortunately, I threw my back out playing basketball last Monday and still have pain. Combined with chronic sleep issues, I have not been physically fit enough to work much on the cars.

I did have a little time on Sunday evening last week to pry back the radiator support enough to pull some of the parts. I was able to disconnect all the coolant hoses, pull the radiator fans, the coolant reservoir, and the radiator. Now that I can see the inside of the frame rail, it is crumpled pretty bad. I am glad that I have a donor piece instead of trying to repair the existing one.

Next up is removing some more of the front parts. I have to figure out a way to remove the oil cooler since the entire mounting is a mangled mess of metal. I guess that I will have to start cutting pieces out.

In other news, I will be working from home next week. That means I will have some breaks to go work in the garage during the day time. This will help me make a lot more progress. I will definitely take pictures this week.

Question for the group: Since I have the front end pretty much removed, should I consider doing any of the maintenance items (such as timing belt, water pump, tensioners, etc.)? I am thinking that they might not need to be done since the car was well maintained. However, I don't know the history of the car and don't want to regret not doing it later. Keep in mind that I still have to get the car titled, inspected, and tagged before any of this matters.

I worked on the car for a little bit last night. I was removing some of the front components and wires. I will be removing the radiator support and oil cooler before the weekend. Then I plan to cut the inner fender and bent frame rail this weekend.

Here is the front of the engine with the radiator, hoses, and fans removed.

Here is the bent frame rail. It is not the best picture, but you can see where the metal crumpled.

I got the oil cooler out and all of the wires out of the way. We will have friends over for dinner tomorrow, so it will probably be Thursday or Friday before I can start cutting pieces out.

While I was in the garage, I was looking at the wiring in the car that will need to be done (since someone pulled out the center console and radio). I found a red and brown wire coming out of the shifter from under the shift boot and they are not attached to anything. Can anyone give me some insight as to what those are?

Looks to me like there will be some 944 welding in your near future. In case there is - I'd like to offer some tips/tricks I've developed. The 944 chassis/body is really well constructed from the factory and that's a good thing. However it also makes things difficult when you are welding on it. The two things I battle constantly are 1) the e-coating on the metal (probably galvanizing of some type) and 2) the seam sealer that seems to be everywhere.

For the heavy layers of seam sealer/undercoating I use a dull chisel that I pre-heat with a MAP torch. Then use the chisel to slice/scrape out the bulk of the sealer/coating.

So wherever possible do the common-sense metal prep before welding and sand/scrape things down to bare metal. But no matter what you will still have small weld fires crop up when the seam sealer catches fire. I have either an air hose or my shop vac (set to blow not suck) nearby and just make it a part of life to occasionally blow out the fire as I go.

And the zinc in the metal coating will fight you too. It likes to splatter so have nearby stuff covered. And as you lay down a bead let the first couple of trigger pulls (assuming MIG) get the zinc hot and then the weld puddle on the remaining squeezes will wick better. And hold your breath as much as possible because the combo paint/sealer/zinc fumes are an arse kicker.

Enjoy.

In reply to Sparkydog :

Thank you for the tips! There are a couple things that I did not think of, such as the seal sealer catching on fire. I will definitely have the compressed air ready and I have a small spray fire extinguisher ready in case anything crazy happens. Looks like having a mask on under the welding helmet wouldn't be a bad idea also.

The part that I am finding difficult now is access to the frame rail. It looks like I will have to remove more of the engine (mainly intake and alternator) to get to the inside of the rail. I will post pictures as I progress.

Stefan

MegaDork

12/13/17 11:45 a.m.

Welding the galvanized metal of the 924/944 frame/body basically creates sarin gas.

So I'd recommend an open door, lots of fresh air and a good mask after removing all of the coating you can.

Stefan said:

Welding the galvanized metal of the 924/944 frame/body basically creates sarin gas.

So I'd recommend an open door, lots of fresh air and a good mask after removing all of the coating you can.

That is a sobering comment. I will definitely be careful when I start welding. Plenty of fresh (and circulating air) with a good mask. Thank you for adding that.

In other news, I spent some time today doing research and it looks like my shifter has the option to be illuminated, which is what the two wires were coming out from under the shift boot.

tedroach said:

Stefan said:

Welding the galvanized metal of the 924/944 frame/body basically creates sarin gas.

That is a sobering comment. I will definitely be careful when I start welding.

Geez, no kidding. Nothing grabs attention like sarin gas.

ValourUnbound said:

tedroach said:

Stefan said:

Welding the galvanized metal of the 924/944 frame/body basically creates sarin gas.

That is a sobering comment. I will definitely be careful when I start welding.

Geez, no kidding. Nothing grabs attention like sarin gas.

I disagree. I didn't notice the s last time i welded galvanize in an enclosed space.

A taser to the nuts gets your attention far more readily.

Having done both, i feel that i can speak with some authority.

Stefan said:

Welding the galvanized metal of the 924/944 frame/body basically creates sarin gas.

So I'd recommend an open door, lots of fresh air and a good mask after removing all of the coating you can.

No kidding. I'll have to be careful welding on mine too then; I didn't really think about it. Breathing that stuff almost instantly makes you feel like you have a cold. Sucks that it's so cold outside...makes it really uncomfortable to keep the doors open while working.

A lot of body shops can't or won't repair Porsches for these reasons. Plus taking panels down to bare metal is a really bad idea since it makes a car that doesn't usually rust capable of rusting. Now battery tray rust is a different story, but we know why that is. The galvanizing does come off in crashes though. One time I was leaving a store and came out to an identical 944 to mine with the fenders bashed on both sides. I freaked out for a second... but then I saw the rust on the damage and thought, "Oh, the car couldn't have rusted while I was in the store, duh" then found mine a few spots over.

Regardless of the weather, I will keep the door open to weld just to be safe. I was able to get out of work a little early yesterday and cut the radiator support and part of the inner fender and frame rail. I wanted to remove most of the twisted metal first and have better access to the front of the engine. Now I can finish removing a couple parts to clear up room around the frame rail where it is bent.

My goal is to have the cutting finished and test fitting the new pieces this weekend. Then I will change the belts, water pump, timing belt and a couple other pieces while I have complete access to the front of the engine. Pictures will come in the next day or two.

Patrick

MegaDork

12/14/17 7:37 a.m.

Please wear a high quality chemical respirator under your welding hood. I removed myself from the world outside my bed last year for 4 days welding alumized exhaust pipes outside. It feels like pneumonia but nothing fixes it but time

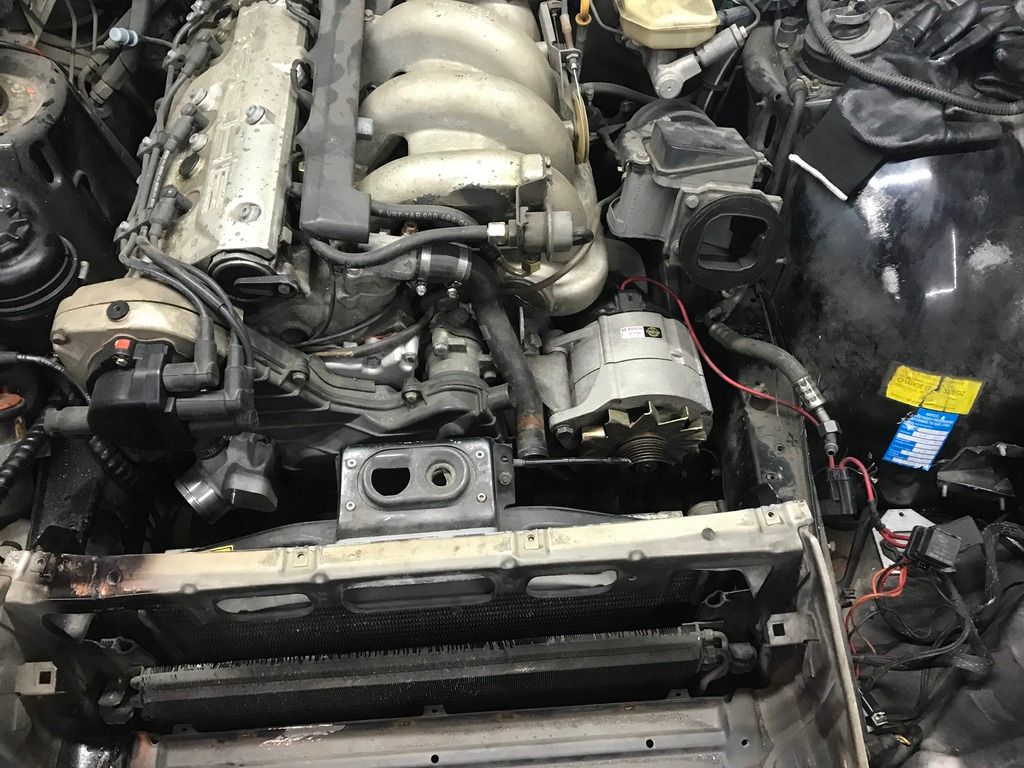

Trimmed a little off the front this week. Started removing some more cables and a couple components to get clearance on the frame rail. Here is the way it sits right now:

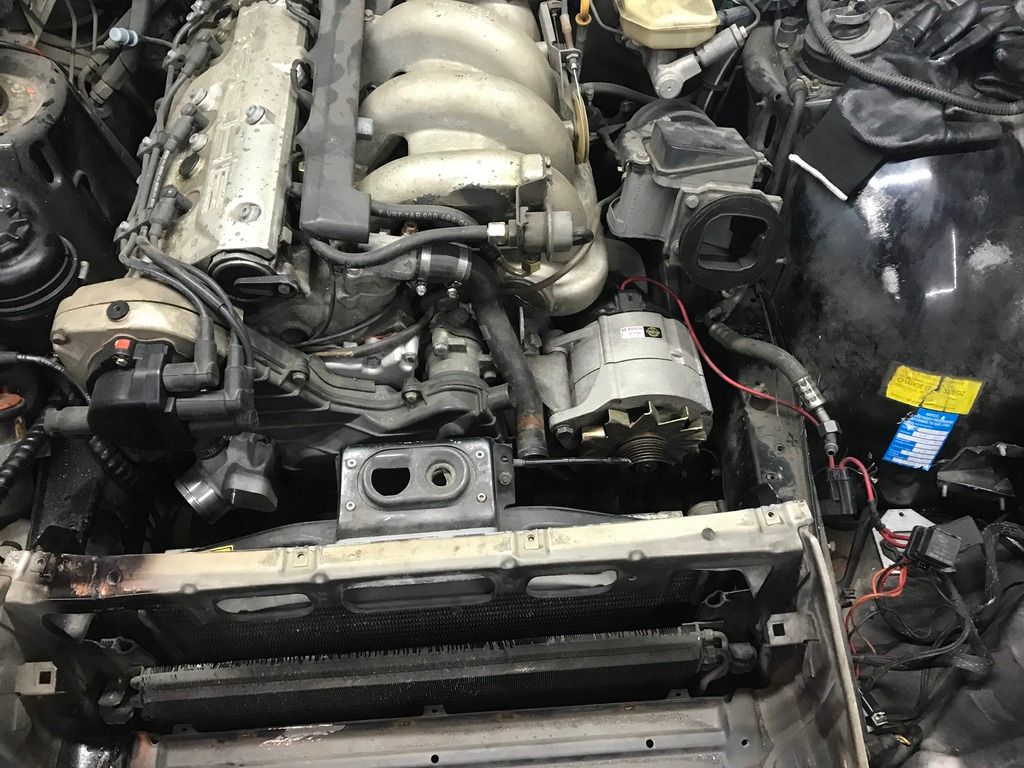

After taking a couple weeks off for the holidays, I was back to work on the 944 over the weekend. First order of business was to finish cutting the bad part of the frame rail out. After removing the alternator I was able to finish the removal.

Here is the bent frame rail:

I decided to stay on the side of caution and replace the water pump and belts. I am glad that I did because the timing belt was starting to rot. First, I had to remove the starter. This sounds like it would be easy but the bolts were so tight that one started to strip. Luckily I got them out but will replace one bolt with a new one. That took 1.5 hours longer than I anticipated. Then I removed the front covers and started pulling apart the pulleys, tensioner, and belts.

Here is a picture for a reference point before removing things:

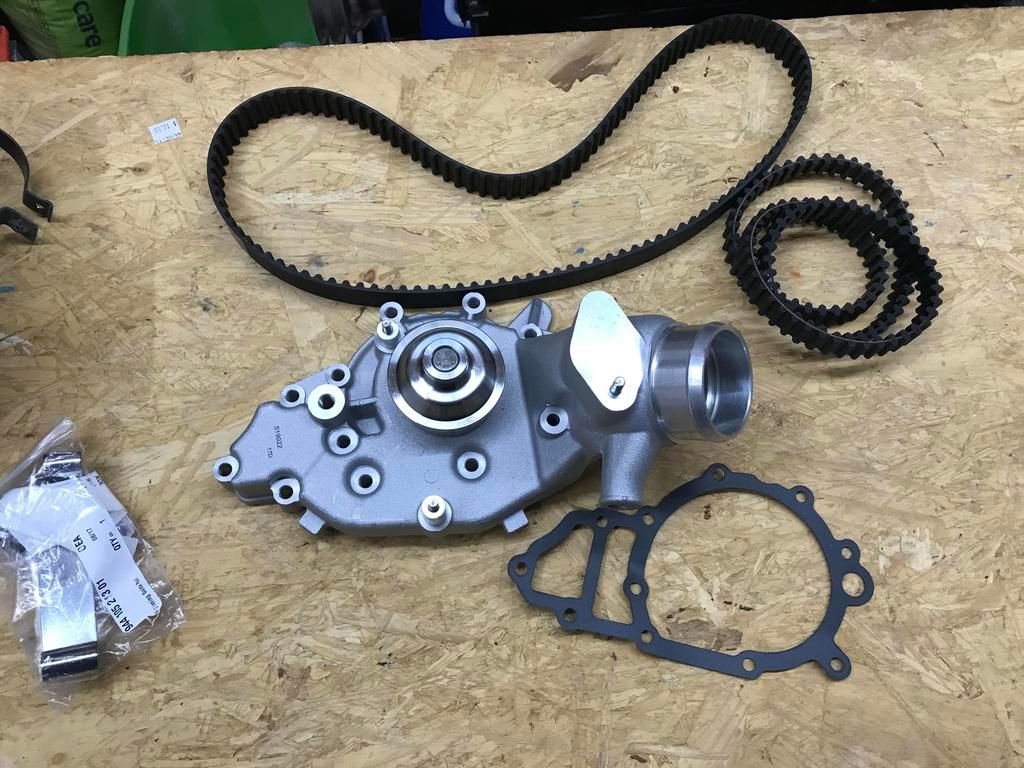

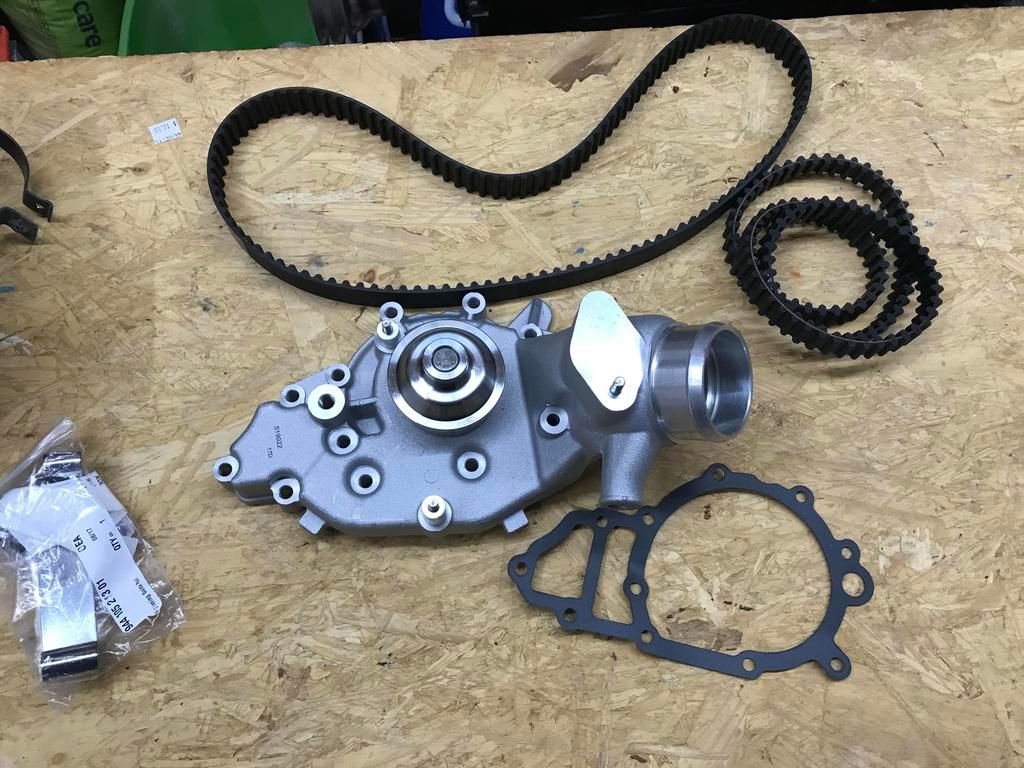

Here is the new water pump, balance shaft belt, and timing belt:

My SBC sitting in front of my makeshift workbench providing a nice view while I work. Absolutely not related to this project:

I had to buy some tools to get two of the gears off. After that, I will get the water pump off. Then I can start working on fabrication of the front.

Yes, gaze at the calm noninterference SBC with its all-steel valves and its non-destructive water pump... also its lack of timing and balance shaft belts.

Spent some time over the weekend on the car. I had a friend come over to help me with cutting, fitting, and welding the front end back together. I needed another set of hands to help hold everything in place. There was a lot of cutting, fitting, trimming, test fitting, and prep work before we got to the welding. Once we got everything to line up, I tack welded the front end into place. When it was in place, I took the time to take measurement from each corner and front to back to make sure it was square. Then I pulled out the level to make sure it was in alignment. A breaker bar and some brute force pulled it into place.

Welding was a lot more fun than I thought it would be. It is pretty relaxing and almost addictive. Now I want to jump on the Chevelle and start fixing body panels. The learning curve on welding wasn't too bad. However, I had to make some mistakes to get the process down. Once we got the surfaces properly prepped and the MIG on the right settings, it was pretty straight forward. After a couple hours of welding, the front end was in place.

The next day, I spent a couple hours grinding welds and re-welding the one that I messed up on. Threw some black paint that I had laying around and stood back to admire the work. While it is not perfect, it is definitely strong.

Last night, I started the long process of putting things back together. I was able to get the alternator, throttle body, and AC condenser back in. Still a lot to do, but it is starting to take the shape of a car again.

That is absolutely berkeleying amazing!

@Sparkydog and @Dusterbd13: Thank you for the kind words. It was definitely a learning experience and took quite a bit of work. I should add that the only reason I was able to get this done was the fact that my wife and kid were out of town for the weekend.

Quick update, no pictures.

I had about a 3 hour window over the weekend to work on the 944. I was going to work on the coolant hoses but needed to get the radiator secured first. It didn't take very long to determine that I am missing the radiator mounts. After searching for a while, I decided that I will have to order new ones. That will take about 10 days through snail mail.

Instead of giving up for the day, I moved on to some other things on my list. I wired the amplifiers for the sound system and got that working correctly. I normally would not have worried about it on a project car, but the previous owner had ran all of the wires to the trunk to connect to amps. It would take more work to pull that back out then it would be to put an amp back in the trunk. A half hour of wiring and I have sound. Then I moved on to routing the main wiring harness on the front of the engine. This had many different connections that I vaguely remember. I spent about an hour routing the wires, connecting grounds, and hooking up components.

I had all of the main wires connected. I changed the distributor cap and rotor (unsure if I put the rotor back on in the right orientation). I changed the balance shaft belt and timing belt. All of this was a perfect storm for a troubleshooting nightmare when I go to start the engine. Curiosity got the better of me and I decided to turn the key to see if it was even trying to start. What could go wrong?! I have a car from the junkyard with an unproven engine and wires just hooked back up based on what I remember from a couple months ago. Without expectation I turned the key.

And the engine fired right up! No codes, no bad noises.

I definitely count this as a win. Now I just have to get the coolant system back together and start reassembling everything.

Cool project!

I would probably plate those welds since they are just butt welds that don't seem to have a ton of penetration.

Plating the welds will seriously help the strength of that area!

Thanks for saving this car!

@wvumtnbkr - Thanks for the suggestion! I will definitely look into that. The penetration is actually better than the pictures. What you see is a second pass that was only mildly grinded down to make it smooth. I kind of went overboard.

Not a lot of progress this week. Waiting on the radiator mounts to get here. Since I was waiting, I decided to move on to getting the front body components ready to be put on. While it is not critical, I decided to go ahead and paint the body pieces black using rattle cans. Even though it is not the greatest paint job, it will look decent from 50 feet. First up was the bumper.

Here is what I started with:

I removed the lights, sanded everything down and shot it with primer:

Then I laid down three coats of gloss black Rustoleum:

I don't think it turned out too bad. There were a couple spots where I laid it down too thick and it started to run. I need to learn to have more patience with painting. I did use a nifty spray paint handle that made it much easier to lay down the paint evenly. It was definitely worth the $7.

I am working on the nose panel but the weather decided to get cold again. I will wait until it is at least 55 degrees outside before I paint more. Just a couple more days.

As a guy that is painted a lot of E36 M3 with Rust-Oleum, it can be wet sanded with thousand grit and buffed

I spent some time over the last two weeks trying to align body panels. This is much more complicated on a car that has been in an accident. I had to modify the radiator support and the headlight mounting brackets to get everything fairly close. The hood now closes and the fenders line up. I still have to finish the pitch of the headlights but I tested them and they do go up and down.