In reply to jmc14 :

You're one of the guys I've been following over the past 10 years. ![]()

I remember your Dragon build, your Cobra-esque build and now your Cheetah-esque build!

I have a few questions for you, if you wouldn't mind?

In reply to jmc14 :

You're one of the guys I've been following over the past 10 years. ![]()

I remember your Dragon build, your Cobra-esque build and now your Cheetah-esque build!

I have a few questions for you, if you wouldn't mind?

I'm just a hobbyist. I build my cars for fun and because I want something different. I'm not an expert or the best at anything. I'm happy to answer any questions that I can.

In reply to jmc14 :

You build cool cars. That's good enough for me.

This is less of a build specific question, but rather a follow up question to a post you had made on another forum, quite some time ago. I'm not sure which one, actually. Possibly Locost, maybe Mad Mechanics, or it could have been somewhere else.

You had mentioned that you had thought of a way to use the Vette T56 as a mid engine transaxle. Care to elaborate?

Ok. I don't know for sure if this would work. But, here is my idea.

Ive used the C5 diff in a couple of builds that eliminated the transaxle. I had an aluminum front plate made that bolted to the front of the diff. The plate bolted into my frame. The plate had a support bearing in it for a new input shaft that I also had made. This allowed me to use a driveshaft and run a front mounted engine with the T56 (or other tranny) that was bolted to the engine.

My thought was to have an input shaft made that would pass completely through the Diff housing. There would be both a new front and rear plate with support bearings that bolts to the diff housing. Then a coupler would connect the shaft to the T56 input shaft. The shifting linkage could be tricky. Or, an auto with paddle shifter could be used.

They use an LS engine in their GTM kit. I think they recommend a Porsche transaxle. I could be wrong though.

jmc14 said:They use an LS engine in their GTM kit. I think they recommend a Porsche transaxle. I could be wrong though.

Yes, using a G-50 in the one I'm building. Ginger speaks the truth about the GTM kits flaws. Used a cable to shift this one.

So Gingerman, did you make the windows roll down?

[URL=https://s240.photobucket.com/user/NOTATA/media/FF%20GTM/004.jpg.html] [/URL]

[/URL]

In reply to jmc14 :

Any chance you could whip up a quickie drawing?

In my head, I'm thinking of a quasi-Corvair setup...on those the mainshaft is hollow, the pinion gear is internally splined to match the mainshaft splines, the input shaft runs past the diff, thru the mainshaft, splined to a modified Saginaw input gear.

I'm just trying to make sure I understand what you're saying, better!

In reply to NOT A TA :

No, I originally planned to rebuild the internal door structure, but as noted in a previous post, I was so sour about the whole deal that I decided to just do it as cheap, fast and easy as I could at the time. Then I managed to find someone who wanted one, and got out from under it while only losing a few grand on my original investment.

I could tell you how I had considered doing it, but it's theory, rather than experience. There are at least 2 guys on the FFcars.com and thefactoryfiveforum.com that have managed to make it work. The only detractor for me with their solution was the way they did it...I can't argue with their success, it just wasn't up to my personal standards of fab work.

Gingerbeardman said:In reply to jmc14 :

Any chance you could whip up a quickie drawing?

In my head, I'm thinking of a quasi-Corvair setup...on those the mainshaft is hollow, the pinion gear is internally splined to match the mainshaft splines, the input shaft runs past the diff, thru the mainshaft, splined to a modified Saginaw input gear.

I'm just trying to make sure I understand what you're saying, better!

I'm pretty bad at drawing but I'll do my best and post it tomorrow.

In reply to jmc14 :

Ok, so I think I figured out what you were saying! (Nothing wrong with your explanation, I mentally visualize, so I had to think about what you wrote for it to stick.)

Correct me if I'm wrong... Bellhousing, diff, gearbox - input shaft that goes thru the diff, coupled to the input shaft of the gearbox?

The problem with this setup is that only 4th gear (input on most RWD gearboxes) is linked to the diff, making it a one-speed transaxle. (If I understood you correctly)

In reply to Gingerbeardman : Drat! I was hoping you might save me some time. Owner of this GTM wants the windows to roll down fully and I've seen the ones you've seen, with the same opinion.

Been following this thread with great interest to see the results. Building a car from scratch is a LOT of work!

In reply to NOT A TA :

I don't have CAD on this computer, so I'll do a paper sketch and post it here with my idea for a cleaner way of doing it.

If that's ok? Feel free to use it, or to jog some ideas of your own.

Envision this , A mount plate off the back of the Bell housing holding a Quick Change center section, the main shaft runs through the QC just like normal but instead of spur gears it drives the trans Main shaft ( or is one and the same) then by means of a jack shaft?at the rear of trans , run back through the top drive of the QC as is normal to drive the R&P. of course a second plate to mount trans to QC,

there are bells for an IRS QC

GTXVette,

That sounds very much like the McKee transaxles from the 60's. A friend (who unfortunately is no longer with us) had one in a Genie that he restored. It looked somewhat cumbersome, but it worked.

Gingerbeardman said:In reply to NOT A TA :

I don't have CAD on this computer, so I'll do a paper sketch and post it here with my idea for a cleaner way of doing it.

If that's ok? Feel free to use it, or to jog some ideas of your own.

That'd be great! I've only looked at them quickly since I've been working on other body stuff but I've gotta come up with something eventually and since I'm "on the clock" time is money for fabrication/ modifications so I'd like to have a plan I think will come out nice and make the owner happy without too many hours. Now if I could just get a set of the new door hinges being used on the Koenigsegg JESKO !!! Hahaha

In reply to NOT A TA :

I'll make some drawings tomorrow afternoon or Saturday morning, then post it here. It won't have dimensions, because I built my GTM 10 years ago, and any notes I did take, I put in a folder that I gave to the guy that bought the car from me.

In reply to GTXVette :

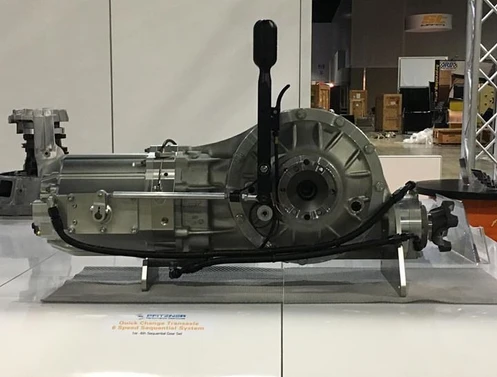

You mean like this?

https://www.ppgearbox.com/product-page/quickchange-transaxle

$18,500

In reply to Gingerbeardman :

If you have a lathe and milling machine you could do something like this yourself with the conventional gearbox of your choice. Gearbox gets inverted, but relatively little other changes needed.Make a collar from the output shaft to the Winters pinion by welding 2 Q.C. gears together. Spline the gearbox out shaft to match. Similar for input shaft, take the teeth off the Q.C. gears! Would have to re-locate the input shaft vertically on the Q.C. unit to match spacing of your gearbox, unless incredibly lucky. Some welding required.

Oh GOD that is Beautiful, if built to the strength of the Center section it would be very Race Worthy, I feel dumb not knowing about this. Oh Well Good Idea, Just too late,

I am going to look for a Damaged R&P housing to remove the Spur gear Carrier, See what it may take to fab it to the S T-10 case where the Tail Housing bolts on. To run a shaft back Forward.

I Believe there is room to flip the ring and then a reverse cut Pinion gear Instead of turning the Trans Over. Or Add an Idler gear to the Spur set.

In reply to GTXVette :

Flipping the trans over does not change its output direction. The reason you need to is to get the input on the bottom. Remember also that quick change rears are not hypoid gears. This helps with the commonality of lubricant you will have between final and change gears. You do not need to flip the ring gear to the other side either, as QC setups that I have worked on have only 2 gears, so you are duplicating this with the change gears, and everything is still aligned as it would be in a conventional front engine RWD platform. You attach the bell housing end of donor gearbox to the spur gear side of the final drive box.

Are the Winters center sections strong enough for 600hp on pavement? Not sure they would handle the torque multiplication of low and second gears. Those are designed for direct drive. Very noisy anyway...

Also that makes the crank centerline very very low.

I do think the Winters housings are symmetrical and the ring can be flipped.

Is that box 6 forward speeds? 5+R or 6+R.

My concerns of torque handling seem justified as no torque rating is offered for that setup. They dont even wave a marketing HP # around.

In reply to bentwrench :

The noise in a Winters is the straight cut QC gears, not the ring & pinion. Straight cut change gears in dog box racing transaxle or gearbox do the same of course. That is part of why I suggested the DIY approach with the "gearbox of your preference" Live axle Trans Am cars often use Winters QC rears BTW.

You'll need to log in to post.