Rodan

UltraDork

4/17/24 3:40 p.m.

And because I can't leave well enough alone, I decided to replace our old, crappy looking mailbox with something fun. At least it gives me something to break away to when my eyes start to go crossed from the wiring... you may see a theme emerging...

This engine swap is really nicely done. Great work! I'm taking notes as I'm putting a K24 into a 914 soon.

Rodan

UltraDork

4/19/24 9:17 a.m.

Thanks.

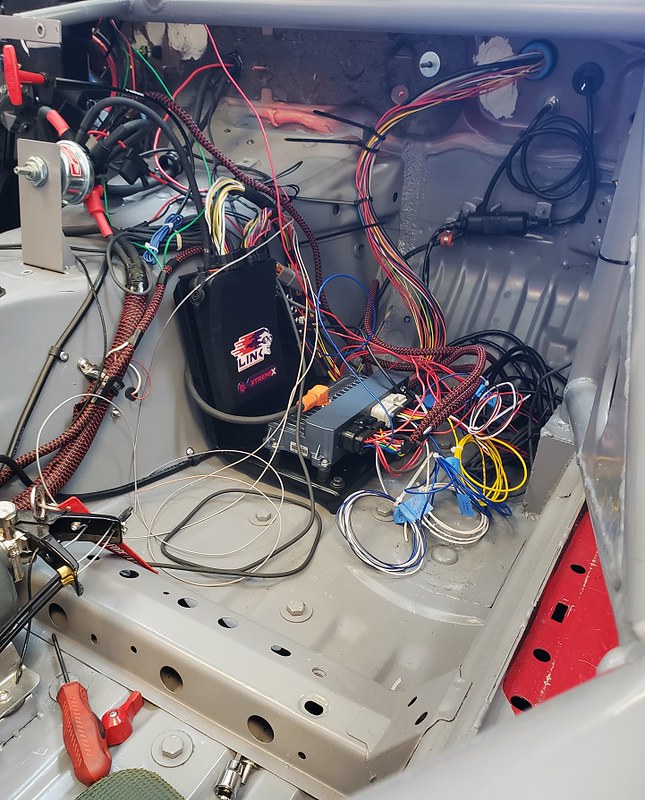

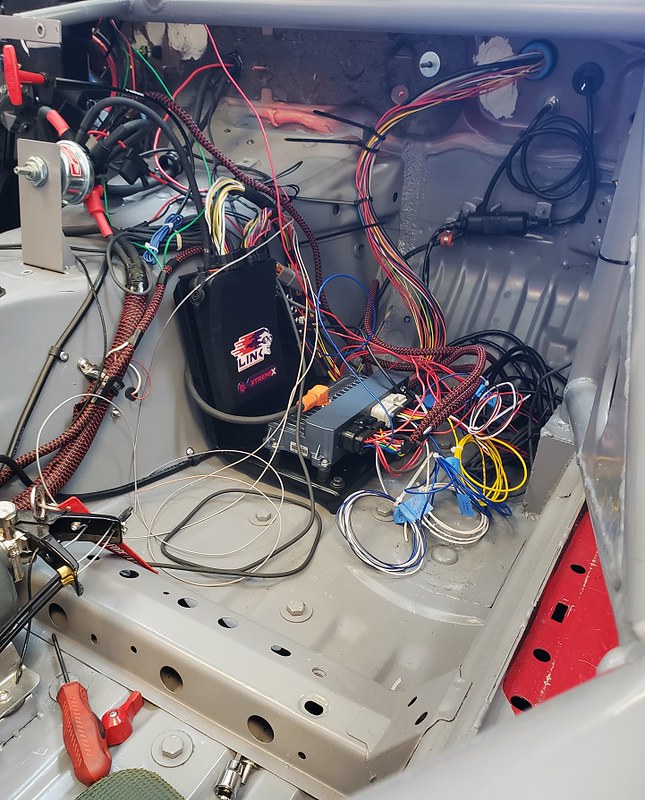

Main harness from PDM/ECU to firewall coming along...

Rodan

UltraDork

4/19/24 9:18 a.m.

And the mailbox is ready for clear coat...

Rodan

UltraDork

4/19/24 6:39 p.m.

Got most of the wiring done. I'm still waiting on a few connectors and a few parts for some last minute add-ons that my tuner suggested. I also need to finish up the CAN wiring for a couple of buses, but need to research a bit as I think I need termination resistors in a couple of them. I have enough done to fire up the PDM and start checking outputs (as soon as I get it configured), and the wiring to the bulkhead connector is done so I can start on the engine harness.

It's still a mess, but will get cleaned up when everything is done and function checked. Nothing more irritating than having to pull a wrapped harness apart to find a continuity break.

Bulkhead connector:

Some of the leftovers...

Rodan

UltraDork

4/23/24 8:34 a.m.

We were out of town over the weekend, and I spent yesterday on the computer working on the configuration file for the PDM, so nothing to show, but progress is happening.

I did finish the mailbox and get it mounted yesterday.

Rodan

UltraDork

4/23/24 7:52 p.m.

Finished most of the underhood wiring today. Just need to wire up the coils and fuel pressure sender and it will be done in front of the firewall. Not loomed up yet, but I want to wait until everything is tested in case I need to address any issues. I really wanted to grind through, but I was catching myself making errors, so decided to stop for the day.

Rodan

UltraDork

4/25/24 12:38 a.m.

Progress and frustration today. Finished all of the engine wiring. All that's left is the CAN connection between the PDM and the ECU, and wiring the O2 sensor to the ECU. Plan for today was to fire up the PDM, upload the configuration and check power outputs. Then I was going to finish up the last of the wiring, start testing the ECU and hopefully fire the car tomorrow. Everything went well with the PDM, got the configuration loaded and got it fired up.

Unfortunately the 12 switch panel that controls everything wasn't working. After talking with AiM, and doing some diagnoses over the phone, they attempted to fix it over an internet connection through my laptop. Didn't work... The switch panel is now on it's way to AiM for repair or replacement... FedEx overnight. Since that panel pretty much controls everything, I'm stuck until I get it back.

Rodan

UltraDork

4/26/24 9:20 a.m.

Quick update, got a call from AiM yesterday, and they found the switchpad to be defective and shipped out a replacement that should be here today.

AiM doesn't have the greatest reputation for customer service, but so far they've been great for me. Their documentation on the otherhand, is pretty lacking...

Rodan

UltraDork

4/27/24 6:03 p.m.

More progress, and more frustration.

Filled the fluids, including the trans, which requires removing the mid-pipe. Fortunately, I planned ahead for this.

These 'fluid extractors' are the best thing since sliced bread for trans and diff fills. Much better than the pumps that leak all over everything. Trans is filled with Motorcraft synthetic 'unicorn tears'.

Plugged in the laptop and got the LINK up and running, and talking with the PDM over CAN.

And that's where the frustration starts. I thought the AiM documentation was poor, but the LINK is even worse. At least AiM had a .pdf I could print.... the LINK user manual is all in the form of a Help file on the laptop, which is cumbersome to access and read while you're trying to use the laptop to see what's going on, and the information isn't always helpful. It's making the learning curve much steeper than it needs to be. Tuner Studio for MS was a lot easier to figure out from a first time user perspective.

I did manage to verify most of my sensors, got the fuel pressure set, and did a cranking test. I'm not getting crank or cam position signal, so I'll be delving into that tomorrow.

That must be a common theme for standalone ECU's, my ECUmaster Black really let me down when it came to documentation. I figured it out and so will you, it just pissed me off when I'd need to rewire a sensor because of the lack of info.

David_H

New Reader

4/27/24 7:50 p.m.

I have been looking into link, the forums on their web site seems to have fairly quick responses from the link team and others with lots of experience on that platform.

Rodan

UltraDork

4/28/24 9:51 a.m.

In reply to adam525i :

Megasquirt has pretty good documentation, and Tuner Studio was a lot more intuitive using it for the first time.

I'm probably a little on the harsh side with evaluating things like this, as I spent a lot of time developing and writing training in my career, and once I understand the process I can often see a much easier way of explaining it to a new user.

All of these things have a learning curve... it's where troubleshooting meets a steep curve that it gets a little frustrating.

Rodan

UltraDork

4/28/24 9:55 a.m.

In reply to David_H :

My tuner recommended it, and I have seen a lot of positive talk on various forums.

I'm registered on their forums and have done a bunch of reading, but haven't found a need to post yet. My biggest complaint is that they don't have a separate user manual, it's all located in a 'help' file in the tuning software, which resulted in constraints on the depth of information and accessibility. See my training comment above...

David_H

New Reader

4/28/24 1:15 p.m.

So once you learn it you can teach me 😀

Rodan

UltraDork

4/28/24 2:50 p.m.

Been working on this all morning without success.

Physical wiring checks out for pinouts and continuity... It's gotta be something in the configuration file that I don't have the knowledge to figure out. I can't imagine both cam and crank sensors being bad simultaneously, even on a used JDM engine.

I reached out on the LINK forums... stay tuned...

Rodan

UltraDork

4/29/24 2:43 p.m.

Car starts and idles!

No start was the result of the pin for the power output for the coils not being fully seated in the PDM connector. I had a fair number of issues with the AiM connectors and the way they snap together... I thought I had it sorted, but one of the pins got pushed back.

The lack of crank and cam signals was just me being an idiot and not being familiar with the LINK software.

Back to the shop to get it off the lift so I can burp the coolant...

That's great news. Congratulations!

Rodan

UltraDork

4/29/24 5:44 p.m.

Thanks!

After almost 6 months, it's nice to be at this point.

Moved the car under its own power out of the shop and turned it around so I can point the exhaust out the door while burping the coolant tomorrow.

Took a look underneath, and man is that exhaust low!!

Tested the electric power steering on the driveway, and it works as advertised. Got a number of little things to sort... the clutch needs an adjustment, coolant burping, wire looming, etc. Also need to build a new splitter. Have a dyno appointment next week.

Rodan

UltraDork

4/30/24 7:35 p.m.

Got a lot accomplished today. I was having some issues with the wideband controller, and after talking with AEM, it turns out the circuit I was using off the PDM (a non-programmable +12V output) wasn't providing enough current for the heater element preventing it from going into ready status. I ended up moving the power supply to another output on the PDM, and that solved it. Also set up the alternator control on the PDM. Finished up the wire looming in engine compartment, and installed catch cans for the PCV/Valve cover.

Next up is getting the coolant filled. Ran it all the way up to operating temps with the nose in the air, and it's still only taken about 1/2 capacity. I thought the Miata engine was a PITA to fill... the K acts like its not circulating any water. Leaving it overnight with a full bucket and we'll see if it sucks any in. There's a port at the top rear of the engine I'll open tomorrow if I can't get it to take water.

That sounds like my Cayman. I think it took 3 tries even using a vacuum setup to get all of the air out of the system.

docwyte

UltimaDork

5/1/24 9:32 a.m.

Vacuum setup works great on my 996, maybe try that?

In reply to Rodan :

I forgot to say that I am hoping that it gulped down all that delicious coolant you left for it overnight.

Rodan

UltraDork

5/1/24 12:05 p.m.

Well, I came out to this this morning...

Didn't have the radiator hose snugged down enough at the back of the head.

Got it to take another 1/2 gallon this morning, so I'm getting there. This was a process with the BP engine as well. It is what it is... PITA.

Most everything else is coming together OK. Hoping to drive it around the block today.

Rodan

UltraDork

5/1/24 3:21 p.m.

Went to drive it around the block, and the clutch won't disengage. It was going into gear fine the other day, but I could tell it needed adjusting for the new clutch. Made a small adjustment today and it won't disengage enough to shift with the engine running. Bled the clutch hydraulics with no change. I'm pretty sure either the master or slave crapped out while it was sitting and moving the car around pushed it off the cliff.

New hydraulics inbound... hope that solves the problem, because I won't have time to pull the trans before my dyno appointment on Monday...

![]()