I haven't had much to update, which is probably a good thing. The check engine light went back off and has remained off. Since they replaced the Adblue tank, my consumption of DEF has dropped dramatically. The last full fill of DEF got me through over 10k miles while before that I was going through 5 gallons in as little as 3k miles. I do have a rattle and a leak in the exhaust right now, but that should be something that's covered by the extended warranty. I need to make an appointment to have them look at it, but I'm kind of trying to hold off at this point since I'm so close to 155,000 miles - might as well have them sign off on the paperwork at the same time so I can hang this on the grille:

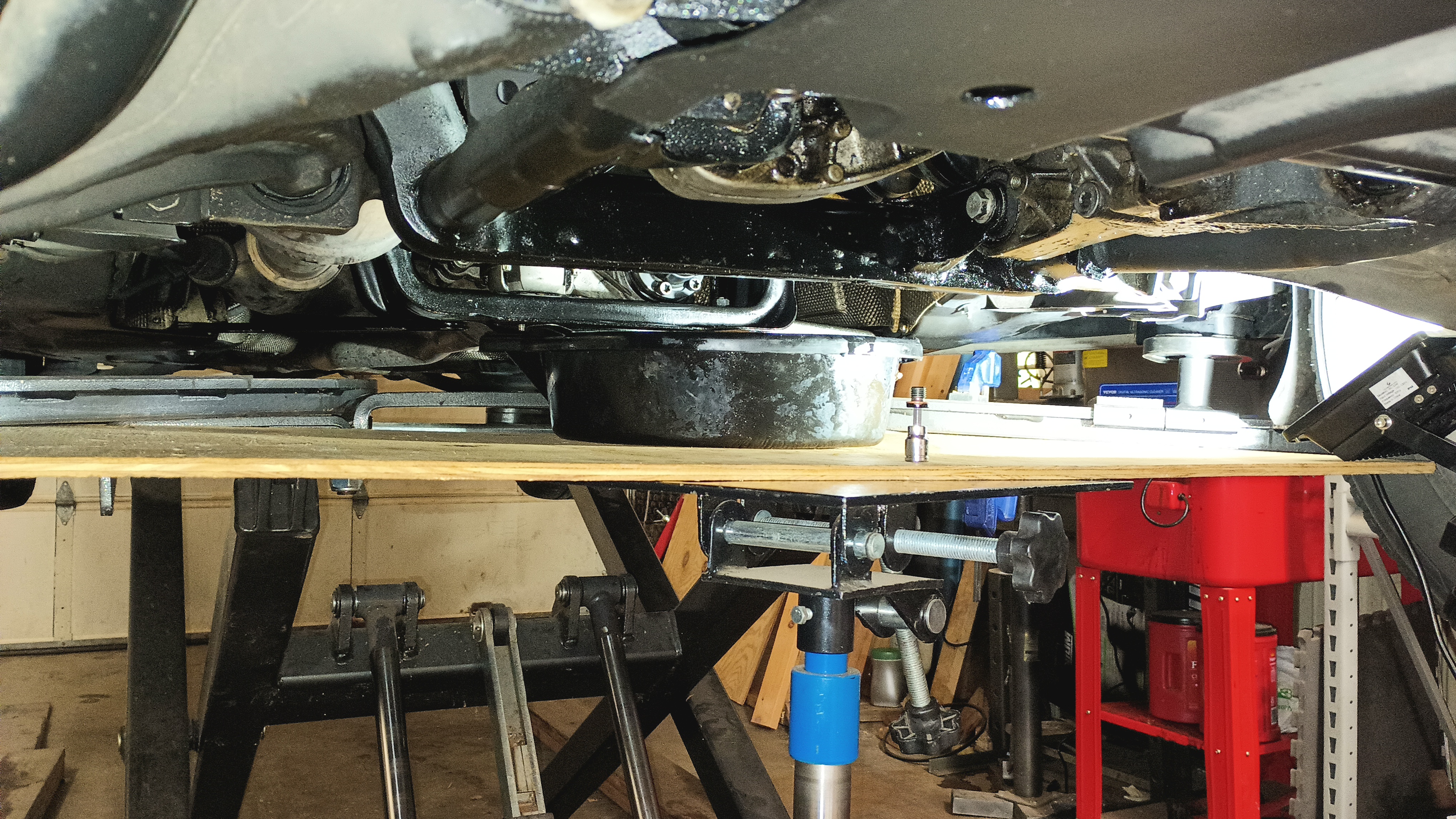

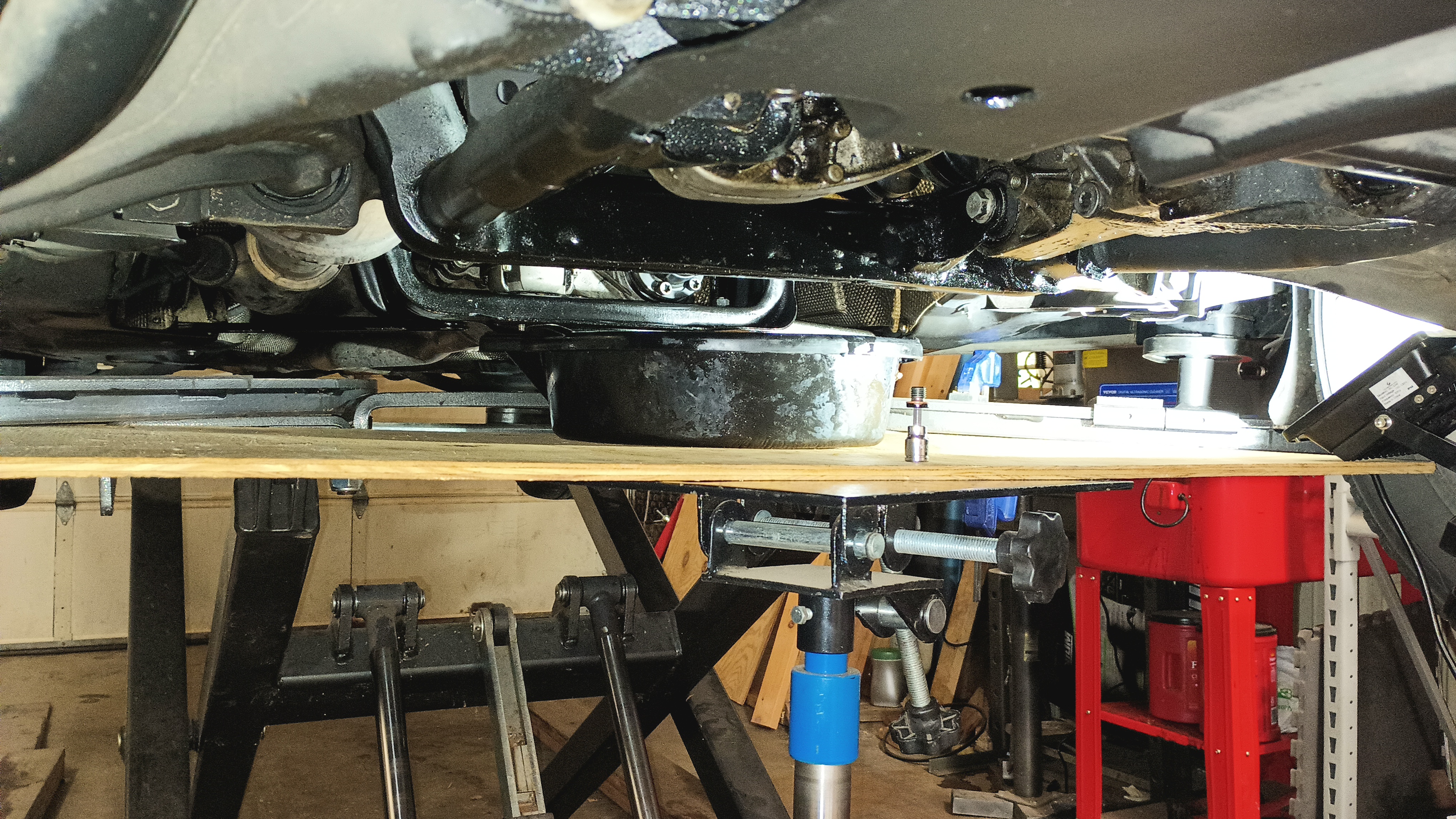

In the meantime, I do have a couple maintenance items that need to be addressed: Transmission fluid and air filters. The trans fluid is a little bit overdue and I've had the box from FCP Euro sitting in the shop for longer than I'd like to admit, so yesterday I decided to get it taken care of. Step one was to get it on the lift in such a way that the transmission pan was leveled out. I screwed around with that for about an hour and could not find a way to lift the vehicle in such a way that it would level. Even trying the little extended pad things in the back:

With just the little pad in the front, it still needed the rear of the vehicle to be up higher - or the front to be lower. I'm a little bit curious how they do that at the dealer without causing the stupid things to tip forward and land on their nose. Finally, I gave up and decided to do it the way I did it last time and use some ramps for the front with the rear wheels uphill.

It took a while to turn the engine so that I could access the torque converter drain plug. It's not difficult, per se, it's just a pain in the butt to crawl under, look through the inspection hole, climb back up, turn the breaker bar on the crank pulley, crawl back under, and so on. It's a 6mm hex head, but you can't really get a socket on it because of the angle. Fortunately, I have a 6mm allen wrench that is a perfect fit.

The rest of the process went pretty unremarkably. Once the TC was drained, I put the plug back in and replaced the inspection cover. That was about 3.75 qts of fluid. The pan is a three-step process: first remove the drain plug and get about a liter of fluid; when the flow stops, use a drift to knock off the little fill neck that's inside the pan and get another whole bunch of fluid; when that flow stops, put the plug back in and remove the six bolts and sprags that hold the pan on and carefully drain that. All in, I think I had about 8.25 quarts of fluid.

Yes, I know the fluid is sold in liters and all the specifications are in liters. But the graduated drain pan that I have is marked in quarts, so that's what we're going with.

Anyway, everything gets cleaned up, the filter pops off and gets replaced, and then the drain pain gets a new gasket, six new bolts, and torqued to 35.4 inch pounds plus 180 degrees. The drain plug comes back out and it gets a new crush washer. The correct adapter from the pressure-filler gets screwed into the drain hole:

And then the pressure-filler gets filled with nice, new ATF. This thing was a hundred bucks, but it's now done three transmission services, so worth every penny considering this is a $500+ job from the dealer.

The guidance is to put back the amount of fluid that was drained plus a liter, so that's what I did.

Once all the fluid is in, just turn the little red handle on the pressure-filler to shut off the valve, make sure that the socket and breaker bar that you used to rotate the engine is no longer attached to the crank pulley bolt, and start the vehicle. Run it through the gears a few times (with your foot on the brake) and then wait for it to come up to temp. I used Xentry/DAS to access the "oil level check" in the transmission module, but the MBII can get the data as well. I also understand that using an infrared thermometer on the pan will get you where you need to be, but I've never tried that. It takes a while, but once the fluid is at 45 degrees C, put a drain pan under the pan and pop the quick release connector off the pressure-filler to let the transmission drain the excess fluid. Once you've got just a tiny bit flowing out, remove the plastic adapter and put the drain plug back in to some number of torques. Don't shut off the engine until the drain plug is in because if you do, the fluid will rush back into the transmission pan and you'll drain too much out. That's all there is to it.

But this is a Bill story, so you know that's not all there was to it.

When I went to put the drain plug back in, I had a blue-tinted fluid coming off the bell housing and forming a puddle under the car. Not good. It looked and smelled like a petroleum product, so I must have screwed something up in the process of getting everything sealed back up. Since it was coming from the bell housing, it must have been the torque converter drain plug. I didn't feel any fluid on the inside of the bell housing, but there's also a cross member and an oil line right there, so it's hard to see or feel into the inspection port. I rotated the engine around again to get the plug, put my allen wrench back on it, and gave it some more twist. For good measure, I also snugged each of the six pan bolts a little more, although I was quite nervous about that since the last time I did this job on this vehicle, I snapped one of the aluminum bolts because my torque wrench was broken. This time when I started it up, I didn't see anything and I was running very late, so I closed up and headed out. Job done!

You're right. Bill story. Job very much not done.

When I got back home, there was still some drippage. I must not have gotten the mating surfaces between the pan and the transmission clean enough. So back to the shop. This time, I decided to work inside since it was dark and cold outside. The only part for which the trans pan has to be level is the level checking, so I just got it up on the lift to take a look. It looked a bit like there was some fluid along the pan, so my assumption was that the pan was leaking. I don't have any more of the fluid hanging around and I can't really get any locally, so I cleaned out a drain pan really really really well and set about draining the pan. Getting the firstfruits was easy - I just held the drain pan under the transmission while it emptied the first liter or so. The second step, after knocking out the fill tube, was going to be more difficult. I had hoped to put the pan on the transmission jack but the scissor lift was where the tranny jack needed to be for that, so I needed to get creative.

I clamped a bit of plywood to the arms of the lift to support it in the rear, and used the tranny jack to support it in the front. That allowed me to put the pan directly under the drain hole so I could have my hands free to knock the fill tube out of the way. When that was drained, the plug went back in and I dropped the pan. I left the pan on the plywood - I added a layer of cardboard to collect the drips - and removed the filter and let everything drip into the pan until I had recovered as much of the fluid as I could. I dumped the pan into the drain pan and set about meticulously cleaning the surfaces.

When everything was clean, the filter got popped back on, the fill tube was installed, the gasket went back on, and the pan got re-installed. I re-used the bolts because I didn't have any extras there at the shop with me. I filled the transmission again using the pressure-filler, and then set about trying to level out the tranny pan. In the end, what seemed to work was putting a couple layers of 2x4 on the oil change ramps, locating said ramps under the rear wheels, and dropping the vehicle so that the rear wheels were up on the ramps and the front wheels were on the ground. Same process to get the temp up to 45 degrees, drain, and cap. For the record, this is how I should have done it the first time. And, as you would expect, no more leaks!

hahahaha! No, you totally expected more leaks. This is a Bill story.

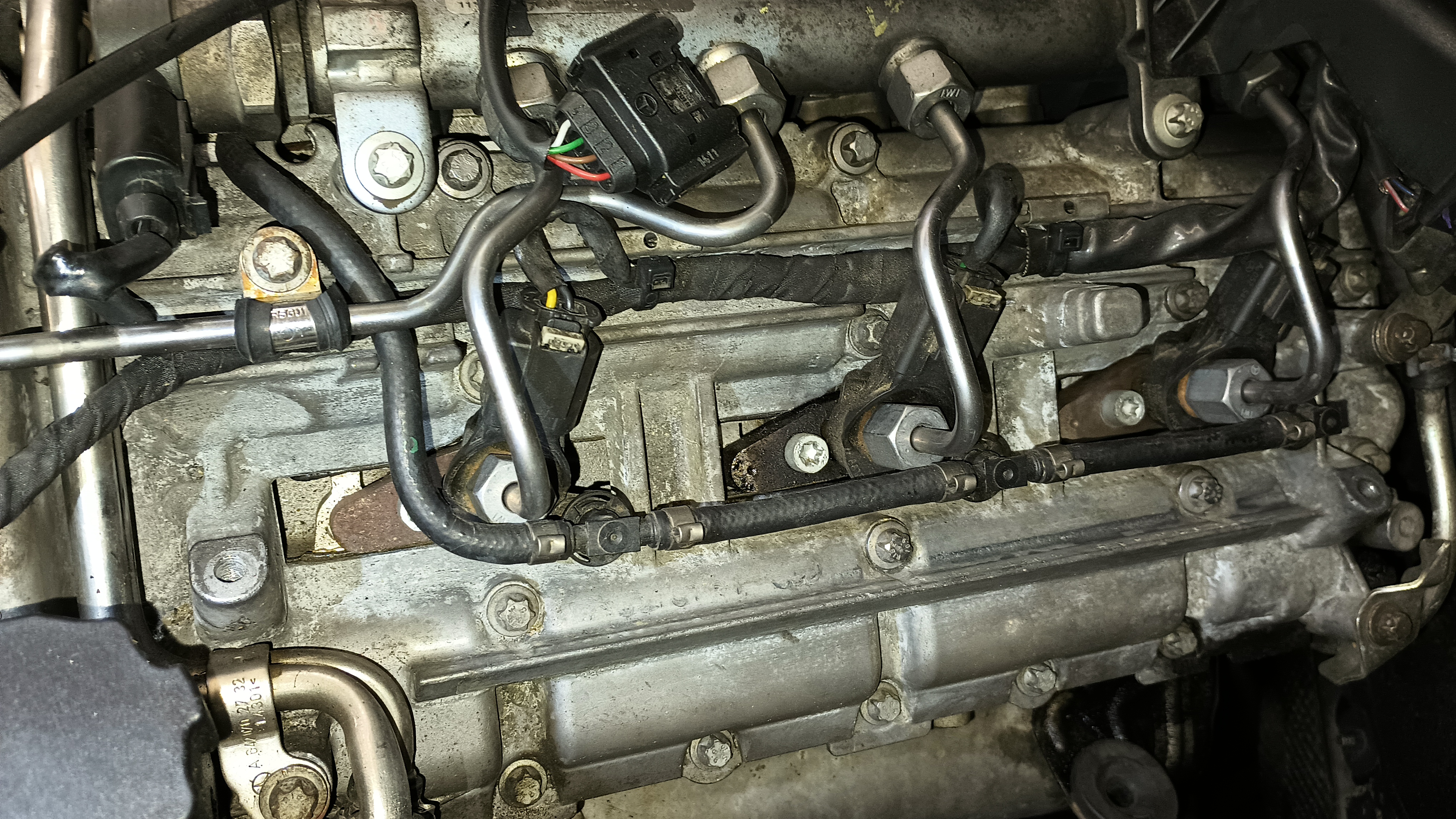

That same leak was still present, so leaving the engine running, I lifted it back up so I could get a look. Here's a riddle for you: What looks sort of blue-tinged like Euro antifreeze and Mercedes ATF, smells, feels, and tastes like a petroleum product, but isn't ATF or coolant?

Diesel fuel. I've got a Mister Falcon-ing fuel leak and it's running down the block, and dripping off the bell housing. The whole second draining and filling of ATF was absolutely unnecessary. As Ben might say, I am not knowing my fluids.

Putting the wheels back on the ground and pulling the engine cover off, I see this:

The little fancy hose clamp on the fuel line on the left was pretty much loose. I replaced it with a worm-type clamp and cleaned up the fuel. Hopefully that should take care of the leak.

At least I am getting really good at doing the transmission service on the 722.9.