Continued:

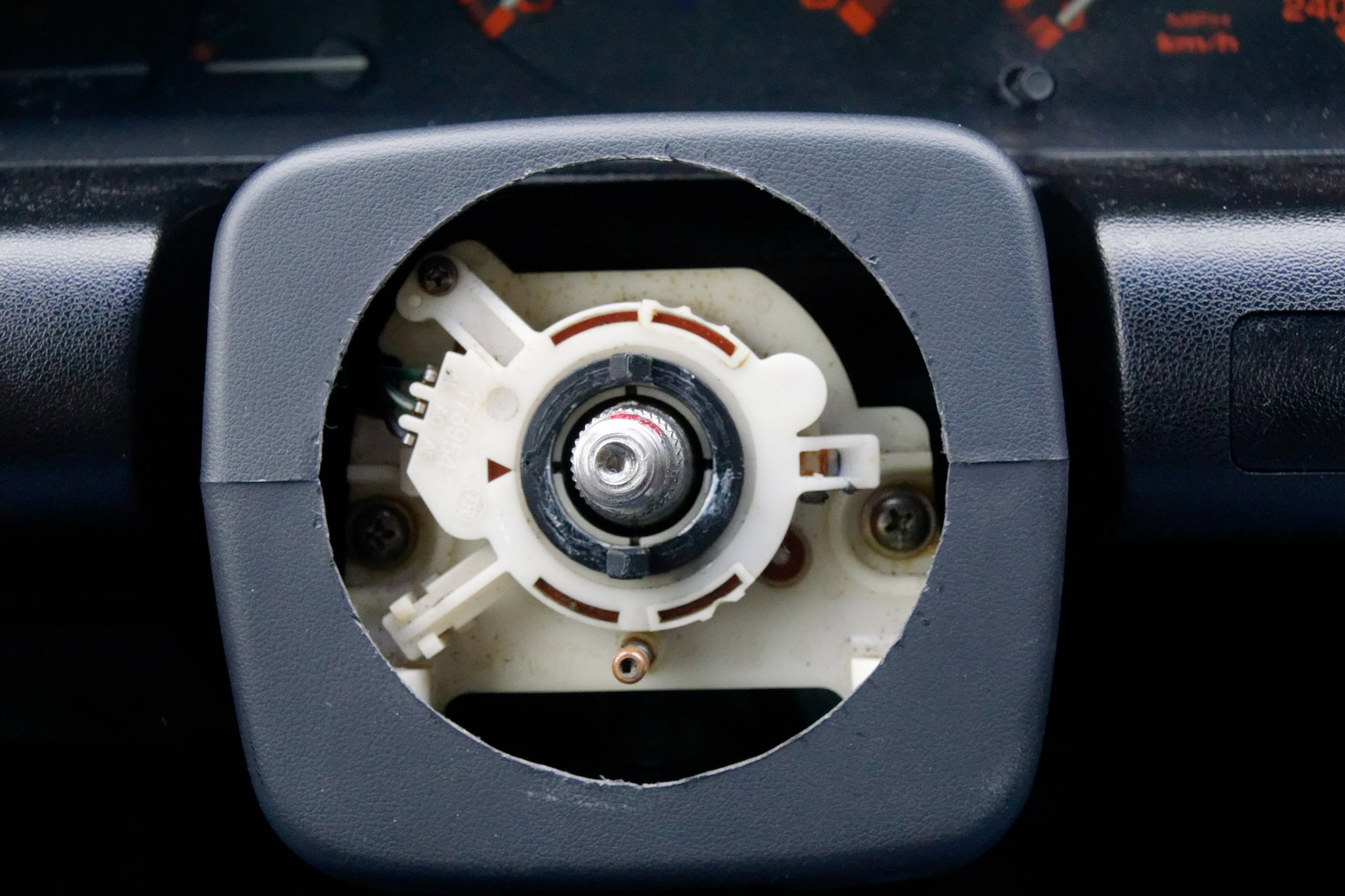

I left the part of the hub that mounts flush against the pulley bare, so I gave it a skim of silicone brake grease to prevent it rusting again. The keyed channel also got some grease just in case. Then I ran a tap through the threads (as I've done with every other thread on this car) and reassembled the pulley:

It could’ve been smoother with filler-primer and sanding, but honestly it’s good enough that I won’t worry about that.

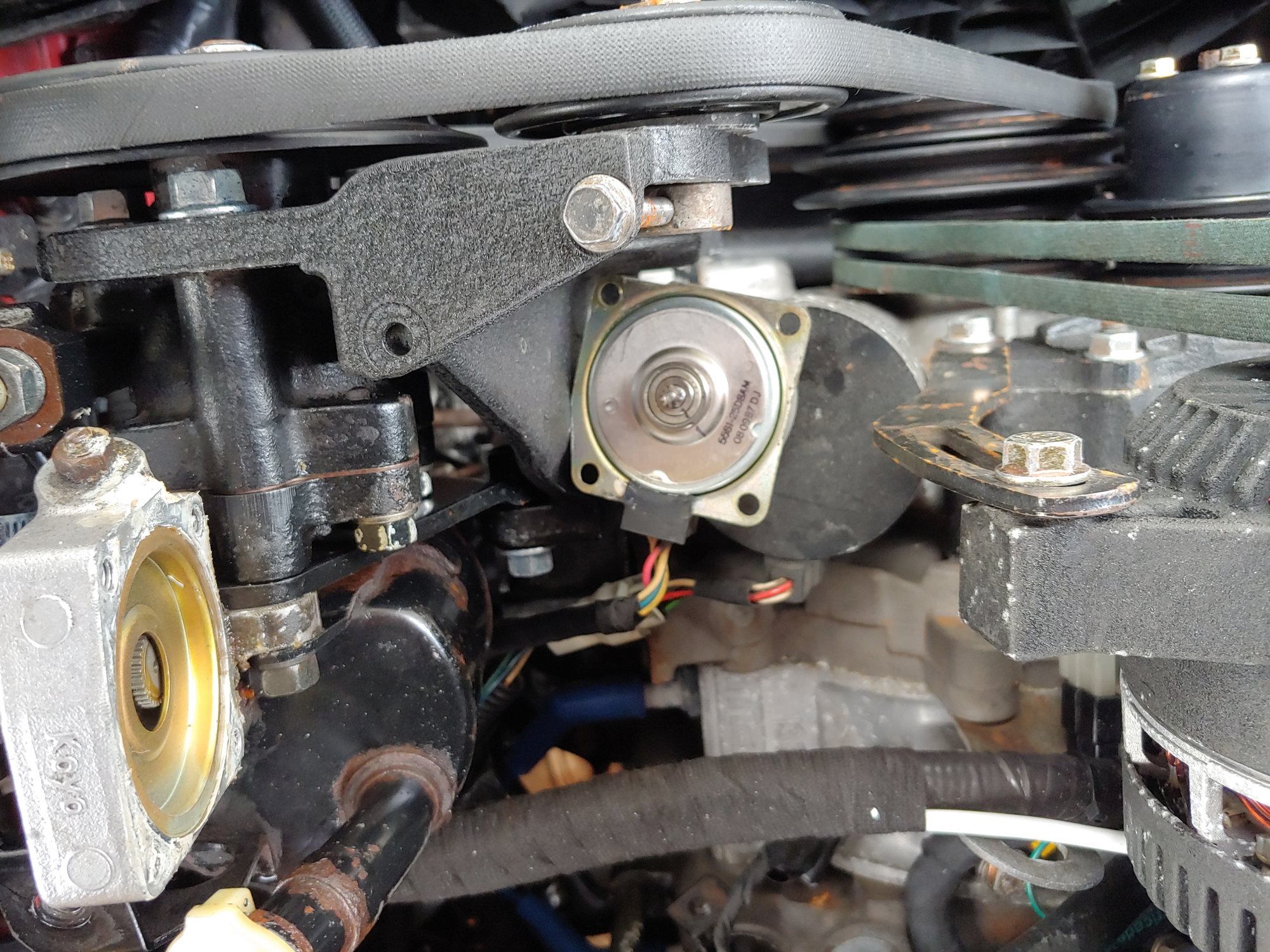

Forgive the blurriness of the following photo:

This is the yoke plug on the steering rack. I had backed it off slightly when driving around without the pump to make steering about 1% easier, but now that I was re-installing the pump I wanted to reset it to factory spec. You need to use a 41mm socket to loosen the lock nut, then torque the plug to 14 ft-lbs. Then back it off 25-30 degrees with a wrench, and snug the lock nut back up before torqueing the lock-nut to 40ft-lbs.

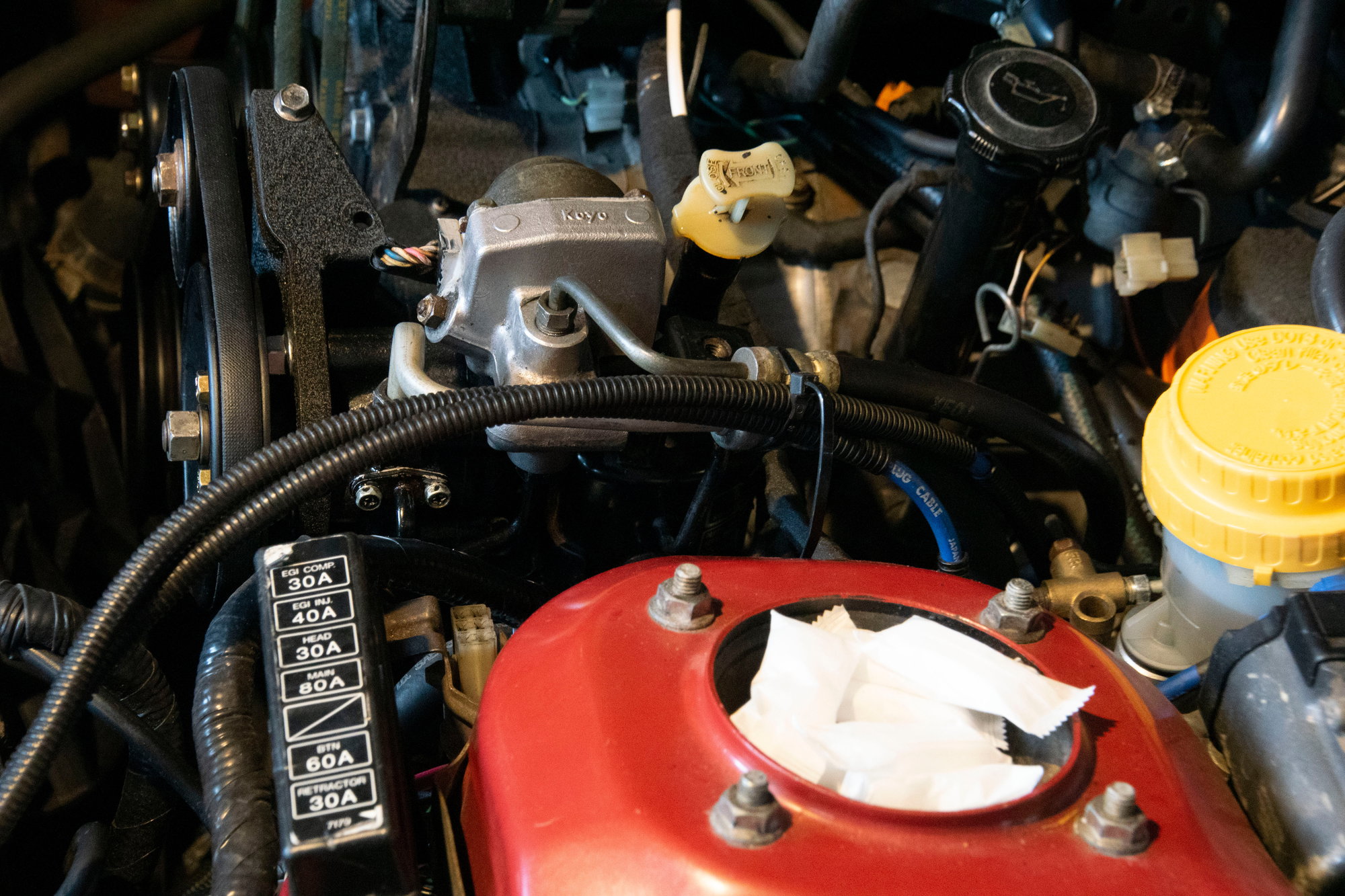

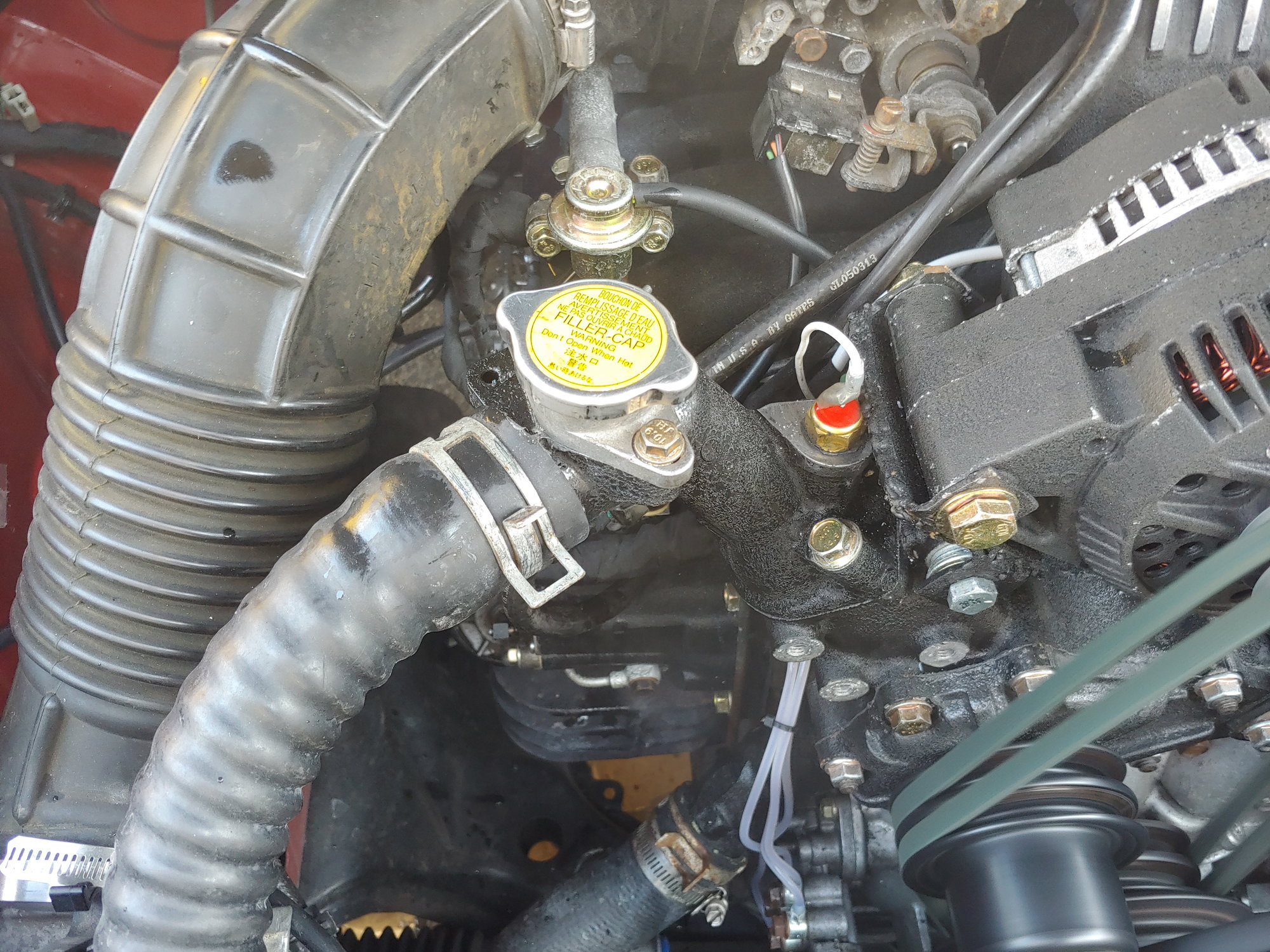

After that I connected the lines:

The slight kinks are courtesy of the previous owner. This is one part of the FC steering system I kind of hate. Instead of having banjo ends on the hoses, or using flared ports on the rack, you have to use banjo bolts and o-rings to connect those adapter tubes to the rack, then connect the flare fittings from the hoses to the adapter tubes. It just irks me and it’s begging to leak. I used all-new Viton o-rings so hopefully I can avoid soaking my nice clean harnesses in ATF again.

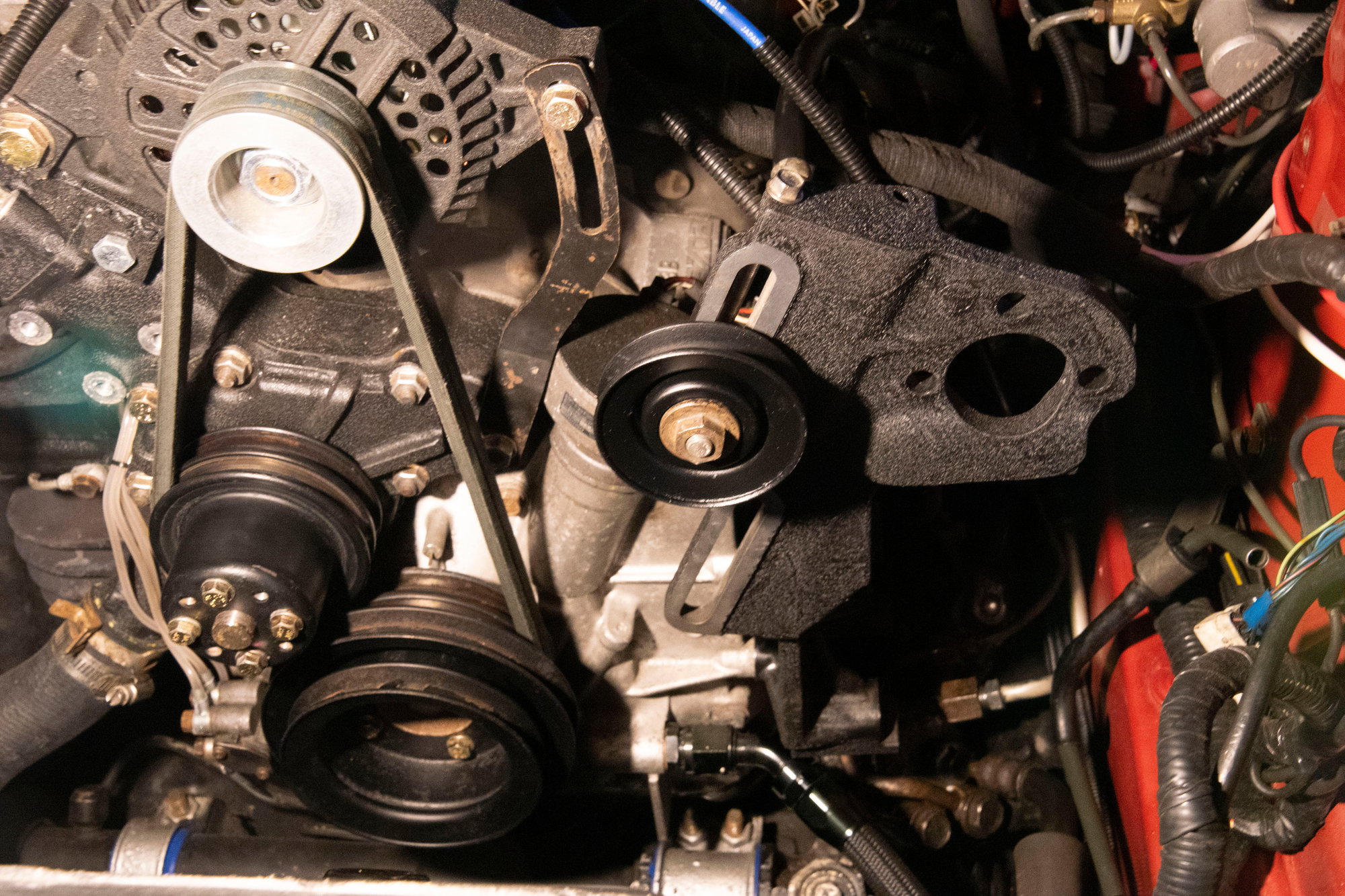

I used some shiny new hardware to install the power steering / AC bracket. I’m still missing the two rear nuts (need an M12 fine), so I’ll get those ASAP. I’m not driving the car until spring anyways.

The AN line for the oil cooler is quite close, but it isn’t rubbing so I’ll just keep an eye on it for now.

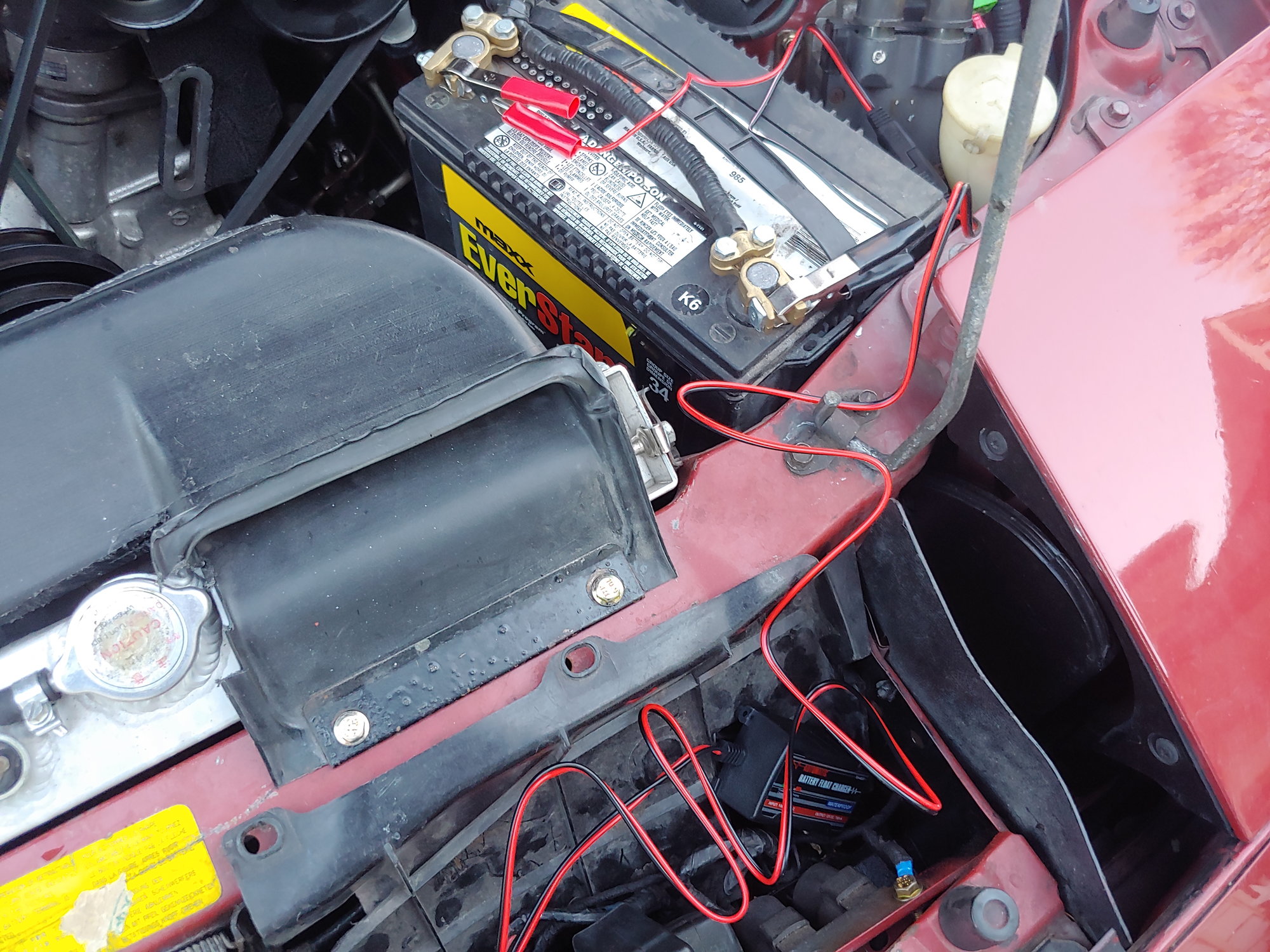

The power steering bracket is back in, idler and other pulleys are reinstalled, everything is ready to go…

Except that I can’t find the four M10x1.25 bolts required to mount the pump. I’m assuming they fell into the same black hole that claimed my pump pulley. Also it’s New Year’s Day, so I can’t go buy any.

Hopefully my next update (“My power steering works!” or alternate title “Leaks, leaks everywhere!”) will be tomorrow.

Happy New Year’s to everyone. Until next time :)