Stampie

MegaDork

5/31/23 11:47 a.m.

In reply to Scotty Con Queso :

We have pictures today!

While looking at the wiring yesterday I decided that I'd remove the old. Following the harness it looks like Sean used the Supra harness for the headlights. That terminates at the passenger headlight. It would be easier to remove if I took off the lower valence. The same valence that we dinged up going down Seans driveway and got a little to much pull when trying to fix it. I've been thinking of replacing it with some cool in my head but executed poorly airdam maybe splitter. This also brought up the fact that we don't have tow hooks in front. So first step was see what we have.

Valence off.

Passenger and drivers side attachment points for tow hooks.

I'm overachieving today. The hood alignment has bugged me so I did it as the afternoon project. Here's before.

I used my caliper to measure gap in height and the pin diameter then decided to wing it. Went out back to the free parts BMW 2002 and the brake booster vacuum hose looked about right.

Always use the proper tools.

How they look installed.

Finished gap.

Stampie said:

I've been thinking of replacing it with some cool in my head but executed poorly airdam maybe splitter. This also brought up the fact that we don't have tow hooks in front. So first step was see what we have.

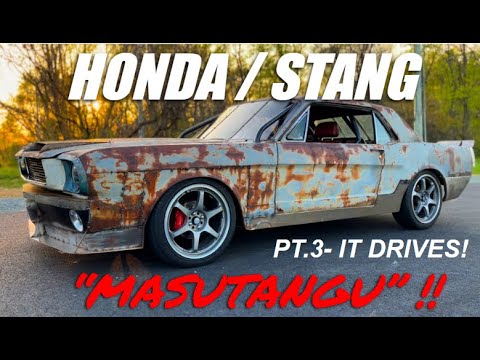

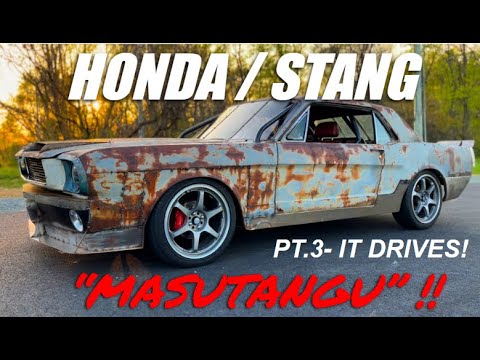

maybe some inspiration?

via the 3-part build series of body-swapping a mustang onto a civic (iirc):

edited to change what video in the playlist was linked to

In reply to sleepyhead the buffalo :

We took one of my aluminum sheets out there and held it up. Looked good. I'm sure it won't when done. I need to figure out how I'm going to make a flange to overlap two sheets and I guess rivet them together.

We used a concrete seam in the Best Western parking lot as an impromptu sheet metal brake to bend a 90° flange

Dusterbd13-michael said:

We used a concrete seam in the Best Western parking lot as an impromptu sheet metal brake to bend a 90° flange

I might have taken a chunk of concrete out when doing that. Lolz.

Decided that Suprang needed a shift knob as well Suprang didn't have one.

First attempt in the press

All welded up. Not bugger weld level but not bad for a redneck using flux core.

Went to the grinder and clean it up and after a minute or so the grinder grabbed it and it went flying. No idea where it went.

Back to Ace Hardware for attempt number two. Decided on a carriage bolt and a C clamp to hold them together.

Welds look better this time. Still hoping to achieve bugger weld level one day.

Went to grind out down using the C clamp to hold it and dropped the bolt again. This time it fell into the guard so we actually have a bonus video.

Stole some white paint from Lil Stampie although not sure if stealing since I paid for it.

Now just waiting on my M12 1.75 tap so that I can install it. Should be here tomorrow.

Mr_Asa

UltimaDork

8/7/23 4:12 p.m.

In reply to Stampie :

If only you knew someone that had a lathe...

And if only that someone had a shop nearby to put their lathe...

I need to go bug John about setting up the welder and getting back to work on the LS head