Watching Calvin do his dyno sessions, as well as many UTube dyno sessions. Is before every session he preloads a program and adjusts from that.

What about orphans? Non typical engines? Engines there doesn't seem to be a standard program for. In my case a V12 or the Slant 6? Or 409 Chevy?

I realize if everything is properly connected it will start and run. But is development time required to get it running correctly before you can work on optimizing your changes from standard?

frenchyd said:I realize if everything is properly connected it will start and run.

If you think this is true, then you are in for a rude awakening.

You have to build a base tune before the engine will run. You need simple things like firing order, base fuel map, timing, some kind of RPM reference based on your particular sensors(crank, cam, etc), fueling strategy, fuel injector flow, MAF or MAP sensor calibration. This all needs to be set up before you can start the engine.

I don't think I've seen any of his videos at the dyno, but if you're tuning a newly set up EMS you'll probably start with some kind base tune you may find on the ECU vendor's website or a tuning forum. Unless a really good base tune happens to be available for your particular engine (not common and I would be surprised if there was one for a Jag V12), some development time would be...maybe not required if you're willing to waste costly dyno time, but at least highly advisable, so that you can get the engine running decently before you get to fine-tuning on a dyno. A lot of base tunes out there are only good enough for puttering around on the street and giving you a sporting chance of not wrecking the engine on the first full-power pull.

Back when I lived in the Caribbean a single dyno pull cost about what a college-educated worker could make in a day, so for those of us on any kind of budget, at least 99% of tuning was done on lightly used roads with a healthy side shoulder in case of a breakdown. Dyno pulls were used for finishing touches and confirming the end result.

Edit: You can of course build your own base tune from scratch but that's not for beginners and can be even riskier, you being the first to ever try it.

Calvin works almost exclusively on LS and Atlas engines. He is VERY familiar with them, and has base maps in his possession which are easy starting points.

You don't have that.

If you are using a MegaSquirt it will provide appropriate default tables to get you started.

I can provide tables to get you started.

There are lots of v12 Jag MS screen shots on the web but be careful about mixing and matching them. If you use them at all.

It's actually a little worse for me. I'm required to use carbs in Group 6 and it's going to be a double bit harder because I'll be using E85.

I have a good set up for 114 race fuel, using 44 IDF carbs but 48 IDA's using E85? Gulp.

Ignition wise then, will I start at a stock firing order and Timing. Then advance it until power stops going up?

Advance until power stops going up, and then to be sure trying retarding until power goes down...it's easy to accidentally run too much advance.

bentwrench said:If you are using a MegaSquirt it will provide appropriate default tables to get you started.

I can provide tables to get you started.

Thank you, I'd really appreciate that. While I'm not ready yet I'll contact you as soon as I get everything ready to go.

Before you ever get to the dyno there are a lot of things to make sure are good. Its a long list and I need to sleep first.

I've used Engine dynos in the past. Until I could predict the outcome and have it happen.

Chassis dyno's seems like it would be the same with the exception of strapping the car down instead of bolting the engine on.

The complexity is the unique issue of an ECM controlling the spark.

Fueling is nothing more than a formula and spreadsheet away.

Spark is just as easy to start off with something soft and ramp in.

Most chassis dyno mistakes are from being in a hurry or being cheap. Ideally, every dyno session should be treated as if it was ready to hit the track. Full tank of fuel and an extra can/pail ready of what you are going to use. Cooling system filled and clamps tight. Transmission full of fluid no excuses. If it's a drum roller, ie dynojet or mustang dyno, appropriate tires and to a proper inflation pressure. Working brakes! Instructions on how to operate your POS.... I'm sure there is more but this is a quick and dirty list I know of off the top of my head.

I like hub dynos but they are hard to find some places. I am lucky and have one about 2 miles from me.

Otherwise, you may need tire goo if you are running big torque.

As mentioned, make sure your E36 M3 is tight. Nut and bolt everything, check your fluids. Don't be the guy to blow out fluids at the dyno, it's frowned upon from experience.

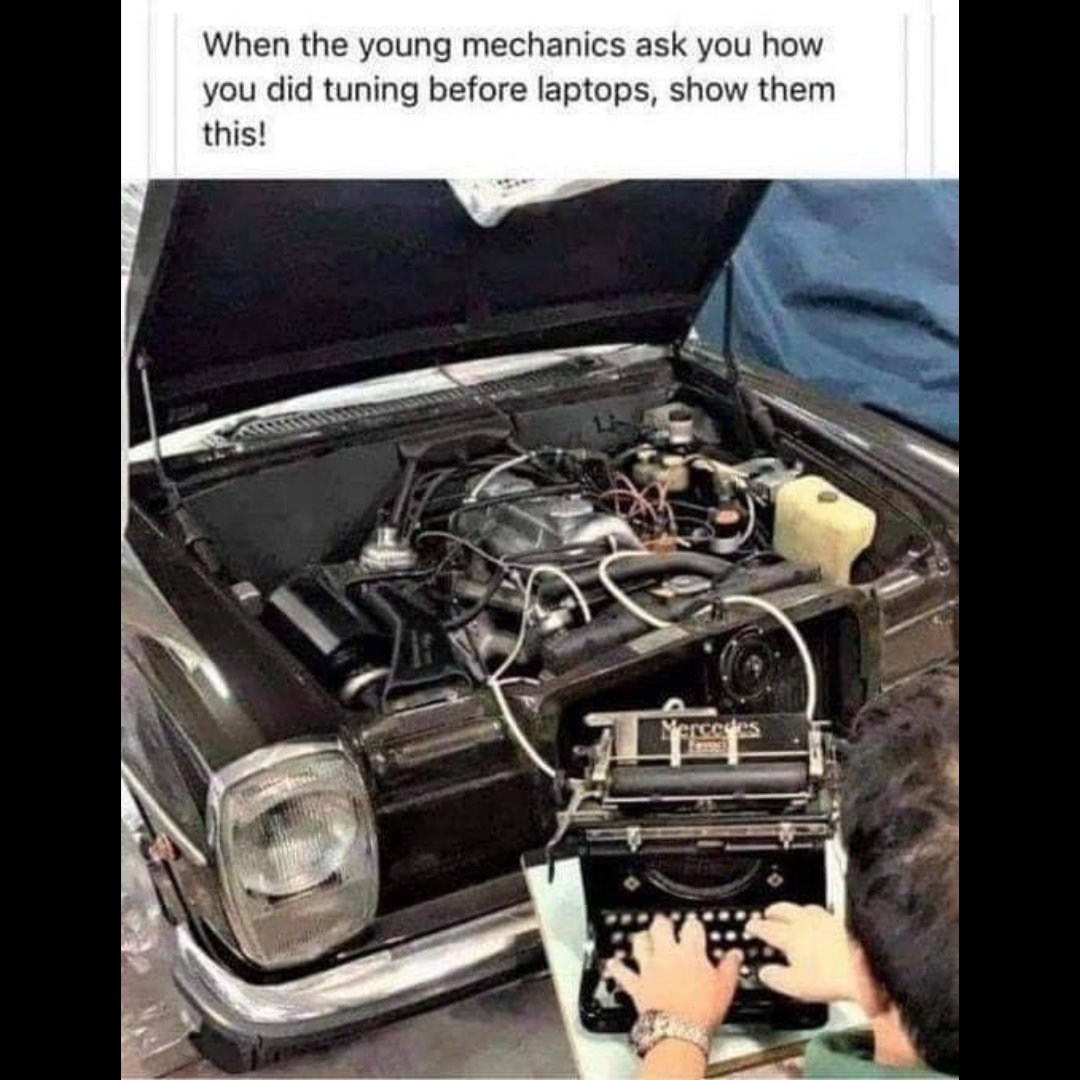

Pic added for fun:

In reply to Ranger50 :

Thank you. But it Doesn't apply to Webers. But I can stick an Exhaust gas analyzer in the tailpipes to get everything close for that. Prior to strapping onto the dyno.

That combined with the broad power range you get from alcohol. I'm hoping I don't spend a lot of time on the dyno.

frenchyd said:In reply to Ranger50 :

Thank you. But it Doesn't apply to Webers. But I can stick an Exhaust gas analyzer in the tailpipes to get everything close for that. Prior to strapping onto the dyno.

That combined with the broad power range you get from alcohol. I'm hoping I don't spend a lot of time on the dyno.

Dyno time applies equally to carbs as it does to efi. You don't need it to get a really good running car, but you need it to optimize it.

Certainly don't need it to copy the distributor curve for digital ignition.

Thanks for that. The only time I'll be at low RPM is in the pits, going to and from the track.

They get real unhappy when you race around the pits ( not to mention dangerous). But if I can keep it running smooth enough, I do have a granny gear for exactly that purpose.

I've used Webers on a V12 before. Even with a nasty billet camshaft it idles smooth and steady at 600 rpm ( the beauty of an even firing V12 )

You'll need to log in to post.