Hi guys

Well, I finally got my car sorted a few weeks ago and took it to fill it up, but had only been using 1 hood pin because I was lazy and planned on driving slow. Well, long story short my hood flew up and broke my windshield. So, I had rust under there at the base of the dash that I couldn't get to unless the windshield was out... so I thought it was a good time to address it. And, while I'm addressing the rust there, I may as well get the rust everywhere else. It ended up there was more than I thought!

Anyhow, I just sort of jumped into it... I didn't have any experience or anything. Since I'm borrowing a mig welder and have scrap sheetmetal from the bent hood, I figured I'd cut out the sections and weld in similarly shaped cuts of sheet metal. It didn't take long to realize I was going to have to spot weld it around and did some searching and apparently that's the standard procedure. The next thing I learned was to cut the patches as close to the original shape as possible, and hence my 2nd repair is considerably more beautiful than my 1st, which you can't really see anyways.

So, another problem I was running into are places that had what appeared to be exfoliation corrosion... and I couldn't tell where it stopped rusting (because the metal was peeling). I found more places like that after I had already made repairs there. Am I going to have to go back in and cut deeper or will rust converter+primer+paint kill it?

Well, after I had most of the repairs done (or atleast covered in primer) I went on vacation for 2 weeks. Well, I just got back and I can already see rust eating through the primer in some spots. I did wirebrush both sides of all the patches as well as around the cutout areas, but I couldn't really get to the inside.

I sprayed as much kleen-strip rust converter in there as I could and then on the front as well, followed by rustoleum primer, and well, here are the pics.

Sample Patch (I doubled over on one side that is 2 sheets thick on the car, everywhere else was only 1)

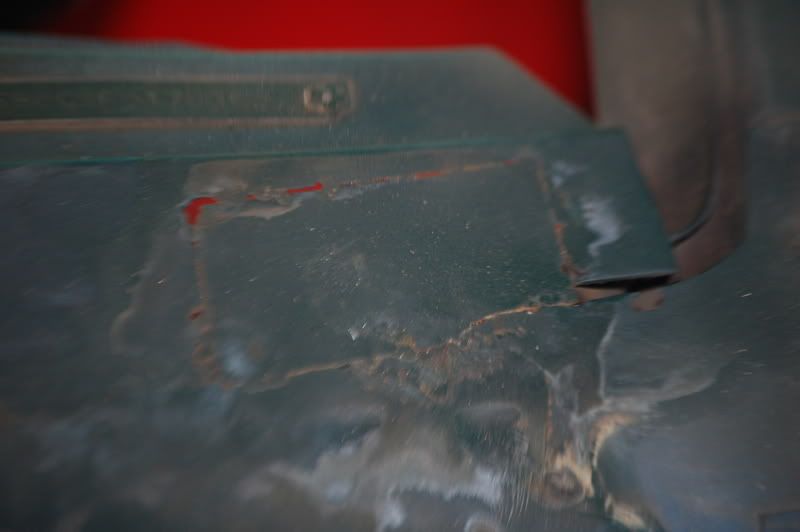

This was my 2nd ever repair after being ground down

Fender comparison. The non-rust fender was already bent when I acquired the car, and the rusty fender isn't bent

Hatch repair. This one was really tough because the bottom line is curved and I really had no reference to where the corner was supposed to be. After thinking about it for a while... I extended the lines to make imaginary cornerpoints on the good side of the hatch, measured that distance, then extended the lines to make an imaginary corner on the top of the bad side, and brought it down that distance to find where the imaginary corner would be where I had nothing to work with, then made a frame from there.

So, that's where I was at when I left. I covered it in primer and was going to fiberglass in the actual curved corner there.

Here's what I had when I got back 2 weeks later!

This one was funny when I was doing it... because the other side had a huge rust hole, and this one had like 1 little rust crack. I ended up fulling a fist-sized chunk of bondo out of this, as well as probably 1 brown-paper bag's worth of brown paper used I'm sure to support the half-can of bondo while it set. Gotta love PO's!!!

This was the other side that was obviously bad. Actually, one side of this repair came unwelded due to that corroded half-metal crap... obviously not good so I'm going back in for this one.

So... I'm pretty sure that's not good. I wouldn't want to put nice paint over that and just have it rust up again, so does anyone here with experience with this have any advice for me? Also, if you see anything bad about any of the repairs please let me know.