I had a few big oaks come down last year right where I want to build a garage barn. I thought a traditionally framed barn with a Zip system would work very well with each other. It wouldn't have to be affixed traditionally but thought it might be pretty cool since the structure would be exposed.

Watchathink?

I have no idea what you are asking. But I haven't been up very long.

spitfirebill said:

I have no idea what you are asking. But I haven't been up very long.

YEAH I'll second this. Put in another way: Huh?

This is relevant to my interest. I may have a pole barn soon.

Zip wall won't last. It's a temporary dust control.

If the wind doesn't get it, the UV will.

I give it less than 2 months.

SVreX (Forum Supporter) said:

Zip wall won't last. It's a temporary dust control.

If the wind doesn't get it, the UV will.

I give it less than 2 months.

Ok, that's why I said Envelope, an old definition of outer insulation iirc? Not sure of the actual terms. Basically putting the insulation outside of the structure for a tighter seal, etc., which can also allow for interior exposure of the frame?

In reply to Hasbro (Forum Supporter) :

You might have to use slightly longer sentences...

I understand what the building envelope is. You capitalized it. Is Envelope a particular product?

Standard insulation such as fiberglass batts will not draft seal.

Are you suggesting using Zip wall for interior walls? As an interior surface on the exterior walls?

Im confused.

In reply to Hasbro (Forum Supporter) :

I believe what you are asking about is a timber frame. Large post and beam construction. You can do it but it is not a fast way to build. Requires a great deal of patience. Look at Ted Benson's books. For ideas.

It is faster if you don't mortice and tenion your beams and just use steel plates to hold things together. But that requires a good understanding of loads and forces to do properly.

The outer wall can be done in a traditional way with insulation inside the beams but you loose some of the depth of the beams and thus the visual impact. Or you can put something like S.I,P. s ( stuctural insulated panels ). On the outside and retain the full depth of the beams.

In reply to Hasbro (Forum Supporter) :

S.i.P.'s done properly dramatically add to the time it takes to build. Plus they really add to the cost.

The chief benefit is heating/cooling costs are dramatically slashed.

There are rules in the building code to deal with timber frame construction. If I remember correctly the minimum size to be considered a timber is 6"x6"

Jack A Sobon wrote a How to book that gives a lot of structural ideas. Easy read with a lot of pictures.

What kind of Oak do you have? White Oak while rot and decay resistant has a lot of tannins and those will cause steel fasteners to rust and rot the wood. You'll have to use stainless steel or silicone Bronze. Or wooden pegs. Pegs if tapered are a very good solution. Although they need seasonal adjusting. A tap to tighten them in late fall and a tap to loosen them in the spring. Maintained like that white oak timberframes last centuries.

if you do not have enough trees to do everything you want, rough sawn green wood is very cheap. Cheaper than sheetrock. ( if you buy it direct from the right saw mill ). Right now many sawmills have a surplus of Ash due to the green ash borer. But every mill has the odd lot of trees. It may be box elder or Iron wood. Stuff they normally turn into pallets or railroad ties.

Here's one version. An exterior version of passive insulation?

https://www.youtube.com/watch?v=P165RxBHBtU

Frenchy, I meant to put your name on the title, not Turner. Yes, SIPS is a version but even more costly. I said traditional framing to avoid post and beam as it's just too labor intense.

So, a traditional barn frame with the insulation on the outside.

You are mushing together a lot of different questions.

Rockwool- very good product. We use it often on commercial structures. NOT CHEAP. I would say it would exceed the cost of SIPs by a pretty good margin. I can't imagine using it in a structure worth less than $500K.

Traditional framing- Traditional framing is not pretty. I don't know why you would want to leave it exposed. Plus, it creates cavities, which make in-wall insulation systems good. Timber framing doesn't create wall cavities- that's why SIPs work well with timbers.

Oak trees- not sure why you mentioned these. Are you considering milling them for timber to make the garage shop? They are green- they would need to be dried. It's unlikely they would have anywhere near enough board footage to make a big impact in the Wood you need to buy. And they would lend themselves much better to being part of a timber structure instead of a traditional structure.

Zip wall- I don't see a permanent use for this product in a garage, but it would be useful to partition interior areas (for example- dust control for an official, or building a temporary spray booth)

Im trying to help answer your questions, but I'm honestly still not sure I know what the questions are.

In reply to Hasbro (Forum Supporter) :

That looks very interesting. Done to the outside it would prevent thermal bridging. Might be an issue around windows. Depends on the window and method used.

Where are you located? Is R8 adequate? Up here in Minnesota I used R30 SIP's for walls and R 50 for ceilings. The return is my neighbor's with typical insulation are spending as much as $1000 a month for similar heating bills and $300 a month for A/C I'm at $300&$50

Oak wood if used as studs probably won't meet building code requirements. And if it's white oak and you don't want the place falling down in about 5 years you'd have to use stainless steel nails or lag bolts.

Depending on where you are you might be able to use large lag bolt assembly. Without the mortice and tenon requirement. To make it work you'd have to do as I did. Have a custom made drill bit made. The pilot hole is the first 5-6 inches. The shank is the next 5-6 inches and the head is a counterbore to sink the bolt head below the surface. They were only $18 ea if I remember correctly. I eventually used 5

I got 5000 stainless steel lag bolts as surplus for 80 cents each for the 1/2x10 size and another 6000 in the 1/2x12 inch size were $1.00 each. Hardened 18/8 plus washers and 3000 6 inch and 1800 9/16x12

Yes I paid more for lag bolts than I did for 55,000 board feet of timbers.

In reply to Hasbro (Forum Supporter) :

Glad you put me out of the discussion! I am not qualified to answer at all if it doesn't have wheels.

I am confused and intrigued by the OP's title and thus waiting to see how it all turns out.

T.J.

MegaDork

7/15/20 12:50 p.m.

So, if I am following this correctly. The OP cut down some trees and now has the space to build a barn. He wants to build a traditional barn and then wants to insulate it outside of the structural components, then some sort of sheathing and/or exterior finish would be on top of the insulation. The goal is to have the barn look like a barn on the inside and the outside, but have some insulation in the exterior walls.

What about the roof? Would you want the same system for the roof?

SIPs sound like what would do this for you.

SVreX (Forum Supporter) said:

You are mushing together a lot of different questions.

Sorry to throw it at you as I did, Paul, et al! I'm truly fishing to clarify the concept and the responses have been varied and helpful. I was into envelope walls when it was called Envelope Theory at a time when I was into pole construction and Trombe walls! Thanks Frenchy, I figured "true" post and beam was over the top for a barn garage but was thinking more along the lines of welding up some alternative connectors (to be approved by an engineer). Use what oak I have for the more up front visual areas. The three oaks are one year old and I was considering using the chain saw method or hire a portable saw mill guy more likely. Trailer the lumber to get it cooked. Yes, put insulation outside the frame for an uninterrupted thermal coat. Even add the eves etc. after the insulation. Probably just double insulated windows. If I can't afford a lot of outer skin insulation I could stagger the wall framing to wind conventional batting through walls sideways - such as 8" deep framing with 2x4s alternating their attachment to outer sheathing, then inner if that makes sense but that would require an inner wall layer. Good for sound insulating, though.

I put a two story addition on my house in Peachtree City, had 8" walls and 12" above, filled with insulation. The garage doors were 3" thick with polyiso sandwiched in the middle. Lots of windows but amazingly quiet and comfortable. Took me three years but it was awesome.

TurnerX1/9, you can give input when I start building cars.

T.J., the trees came down without my approval. During a storm a microburst hit them. Terrifying! Tallest was 115" and it took the others in domino fashion. They would have taken out the garage so there's the silver lining. Not sure about the roof. The house will have galvanized.

In reply to Hasbro (Forum Supporter) :

If you attempt to kiln dry the timbers you'll make a big mistake. It takes roughly an inch a year to air dry and even that's a mistake. Kiln drying will turn timbers into pretzels plus induce all sorts of stress checks. Ugly!

Work the timbers green. Your cutting edges and arms will thank you.

If you assemble it green properly it will warp and twist but eventually get back to reasonably close to true. The Amish work their barn timbers green.

There are certain tricks you can do to make timbers look more finished. Make yourself look like a real skilled timber worker. I'll be happy to point you in the right track.

One thing, don't chainsaw your timbers. Much better off getting a local sawmill to do it for you. A good sawyer will make much better use of the wood and won't waste time and money trying to save every piece of wood. If you want a list call Wood Mizer to start. But check around. The cheapest source of wood is someone who does a moderate amount of pallets and Railroad ties maybe a 2nd or 3 rd generation sawmill operator.

Are you talking about the zip system sheeting with integrated vaper barrier like this:

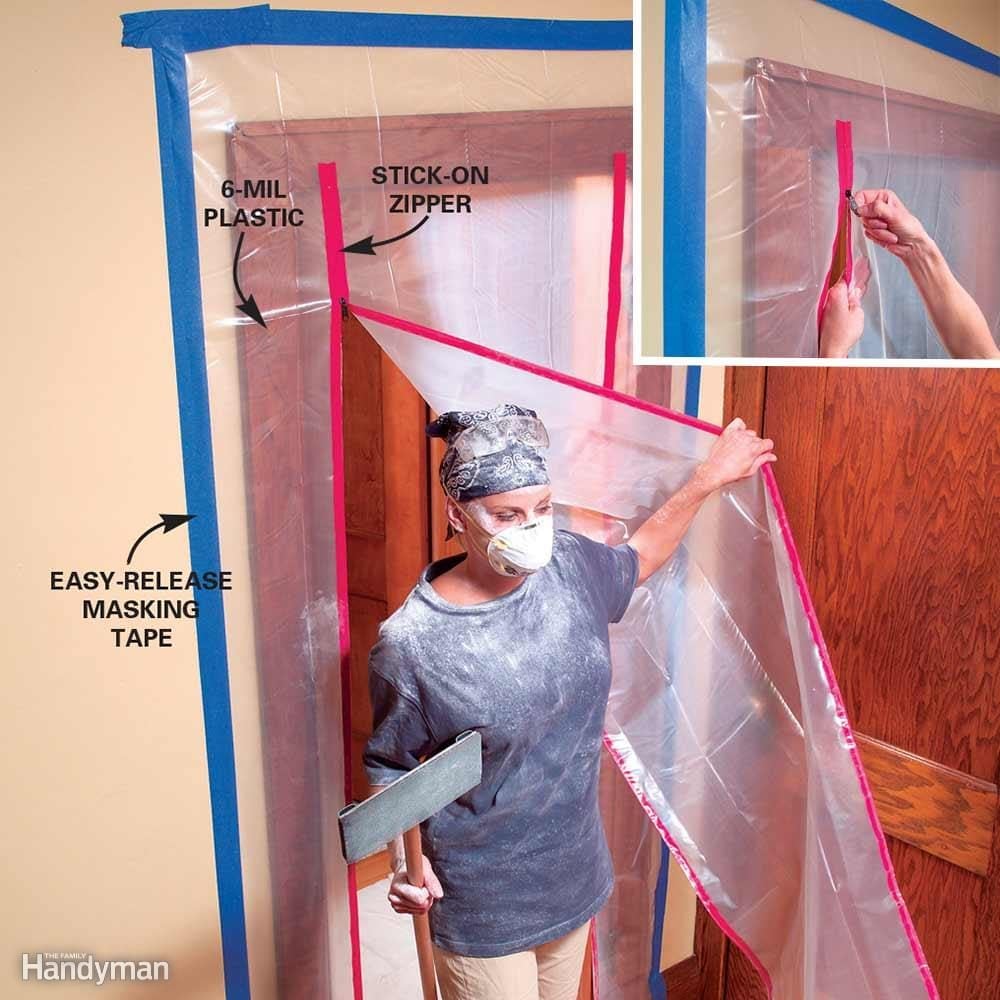

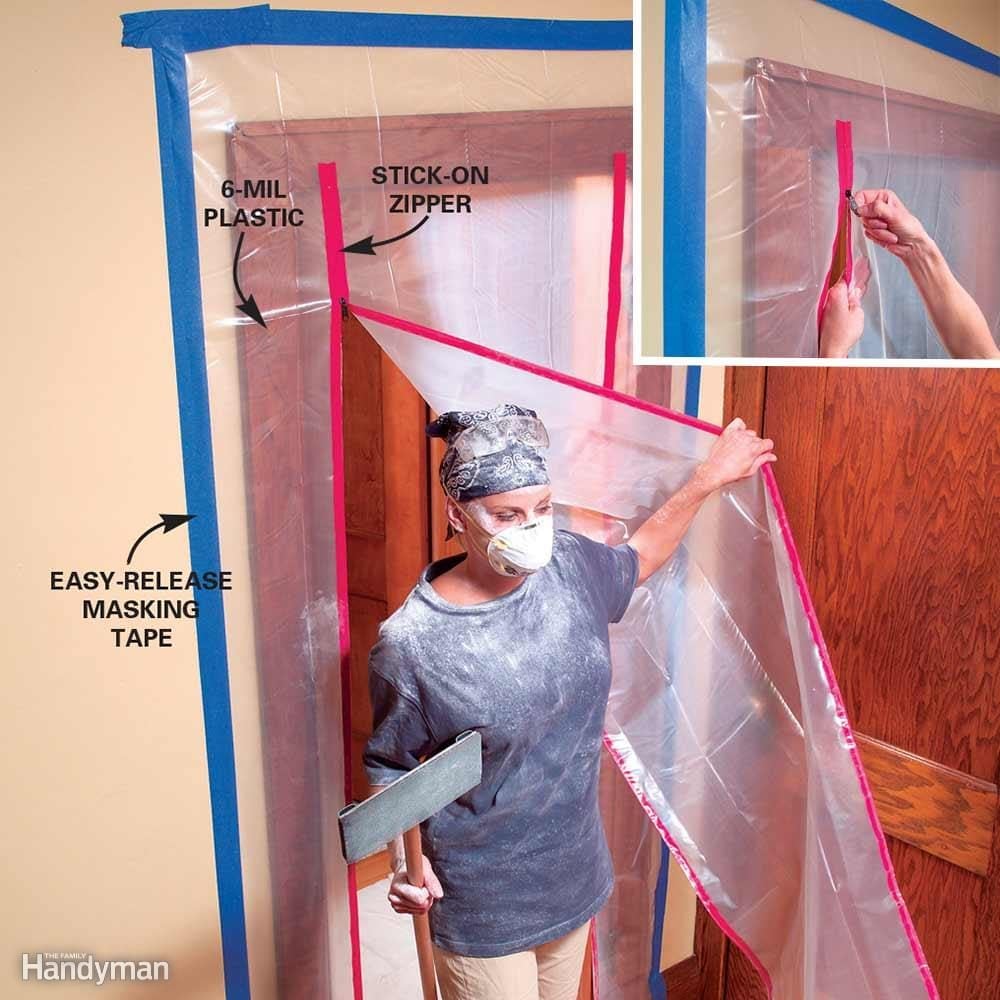

Or zipper walls for dust control like this:

In reply to xxsportscar :

+1

You may have just figured it out. I've been talking about the zipper walls for dust control. ZipWall is a brand.

Maybe you're right- he may be talking about the sheathing. (Which is technically called Zip System sheathing)

...all of it is overkill for a garage in North GA.

In reply to Hasbro (Forum Supporter) :

It sounds like you want to build a barn yourself using lumber that literally fell Into place. I think othes have noted there area lot of challenges with milling green lumber to use for construction, maybe consider some other options to convert the lumber to cash then to store purchased framing lumber?

On the sheathing/insulation. The zip system is cool as it combines the sheeting and house wrap so for builders there is a labor savings to offset the added material costs. I don't know how zip compares to regular house wrap for air sealing but it looks like it's harder to goof up as long as you tape/roll the joints. They have a versions thats laminated with foam and again I think the advantage is In the labor savings.

What are your goals with this barn, Cheap, insulated/air sealed, astetically spectacular? I think you need to creat a set of goals for this barn and you can compare some methods And have a better idea as to which construction method will best fit.