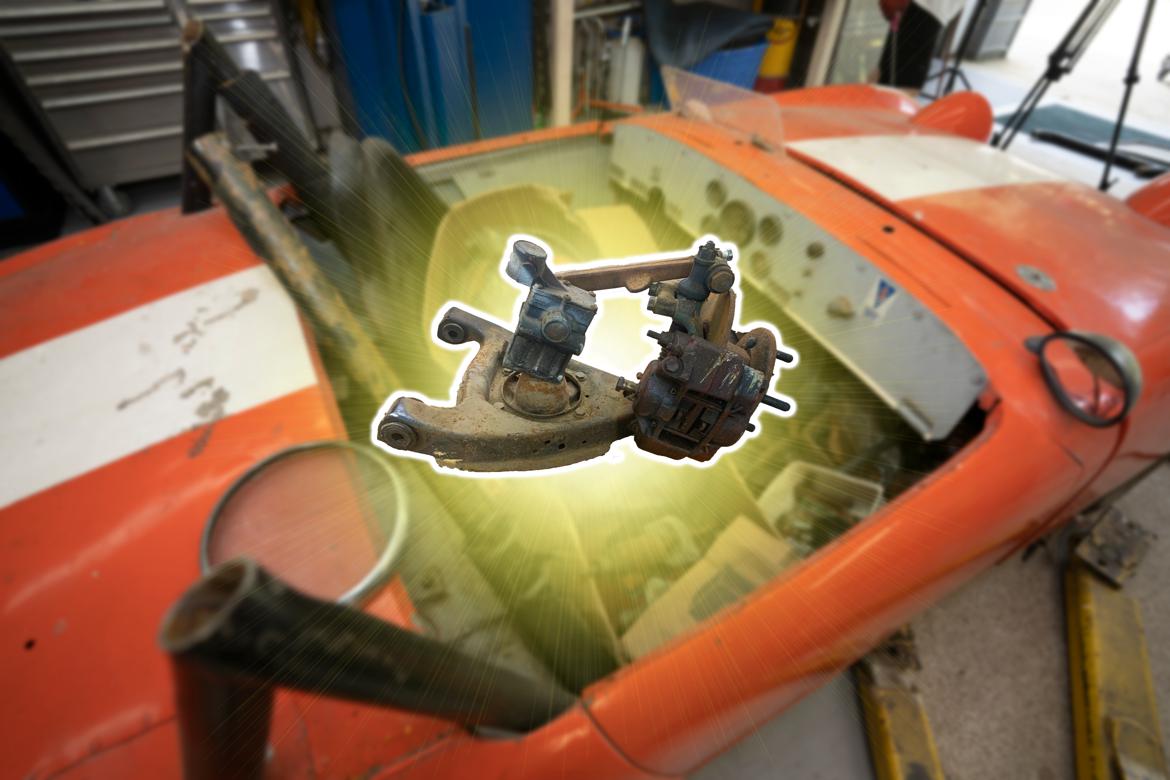

Our Bugeye Sprite race car came with a lot of extra parts–parts stuffed in the car, parts packed into old, tattered boxes.

Did we score gold or just stuff that would need to be taken to the dump?

We sent pictures of our newfound suspension parts to Sprite Expert Tom Colby at Speedwell Engineering.

He gave us this report:

“To be nice, all of the stuff here is 100% worn-out, more or less stock components, and all poorly done shade tree mechanic-type work.

"Those are stock leaf springs, a bad attempt at a Panhard bar, and an Addco rear sway bar, which is way too stiff for any Sprite (from street to vintage racing to SCCA racing) in regard to the size of it.

"I also noticed one of the front brake hoses is chaffed to the point of bursting. It's typical stuff I've seen for my four-plus decades of building these.”

The good news?

Um, not much.

“Every single part in the pictures just needs to be disassembled, stripped to bare steel, examined, and then replace just about everything that pivots. Make sure to have the spindles Magnafluxed, and if the front brake rotors are within spec, have them turned. They are way better than the new, very inexpensive rotors.”

Some more advice:

“Use the Moss Motors tapered front wheel bearing conversion kit. Cut/remove any of the rear axle housing brackets that were added on previously and start from new.

"And finally, check the numbers on the rear axle shafts. They need to be a prefix BTA (denotes 1275 spec), not 2A (948), or better yet, run aftermarket, uprated axles. Let me know if I can help and have fun!”

Next, we did a little math to confirm that our front springs were in fact not uprated. If you measure the free length, wire diameter, overall mean diameter and the number of active coils, you can plug these numbers into an online spring calculator.

Some talk from Grassroots Motorsports regarding active coils:

“If two coils are in contact with one another when in compression, they are not active; the contact (coil binding) prevents the coils from acting as spring elements during spring compression. However, if both ends of the spring are secured and the spring is extended (rather than compressed), the bound coils will become active, since the coils become unbound during spring extension. Suspension springs commonly have two bound coils at each end of the spring. These coils would not be counts when determining N.”

[How to calculate spring rate–and how to understand cutting coils]

Our springs measurements:

The spring calculator on the Acxess Spring site said that our front springs measured about 250 lbs./in. As a stock Sprite supposedly has 271 lbs./in. front springs, we think it’s likely that we just have stock springs.

So, while not rusty or damaged, we essentially had worn-out stock suspension. One bright spot that we discovered, however: Our Sprite did come with up-rated front spindles, so we could knock those off our shopping list.

And, of course, our Sprite had also already been converted to front disc brakes, which were not introduced until about 1962.

Some other good news: Our MG Midget parts car had the better rear axles, bigger rear brake wheel cylinders, and more modern emergency brake hardware.

All and all, while we didn’t hit the lottery with our Sprite find, we had enough to work with and can now work on our shopping list.

View all comments on the CMS forums

You'll need to log in to post.