alright, budget first

previous total: 7813.15

subtract 500 for the tranny parts sales

brings car to 7313.15

now, the money ive spent:

71.15 at summit for oil pan gasket, exhaust clamps, and rear main seal

215 for mass backed carpet from previous post

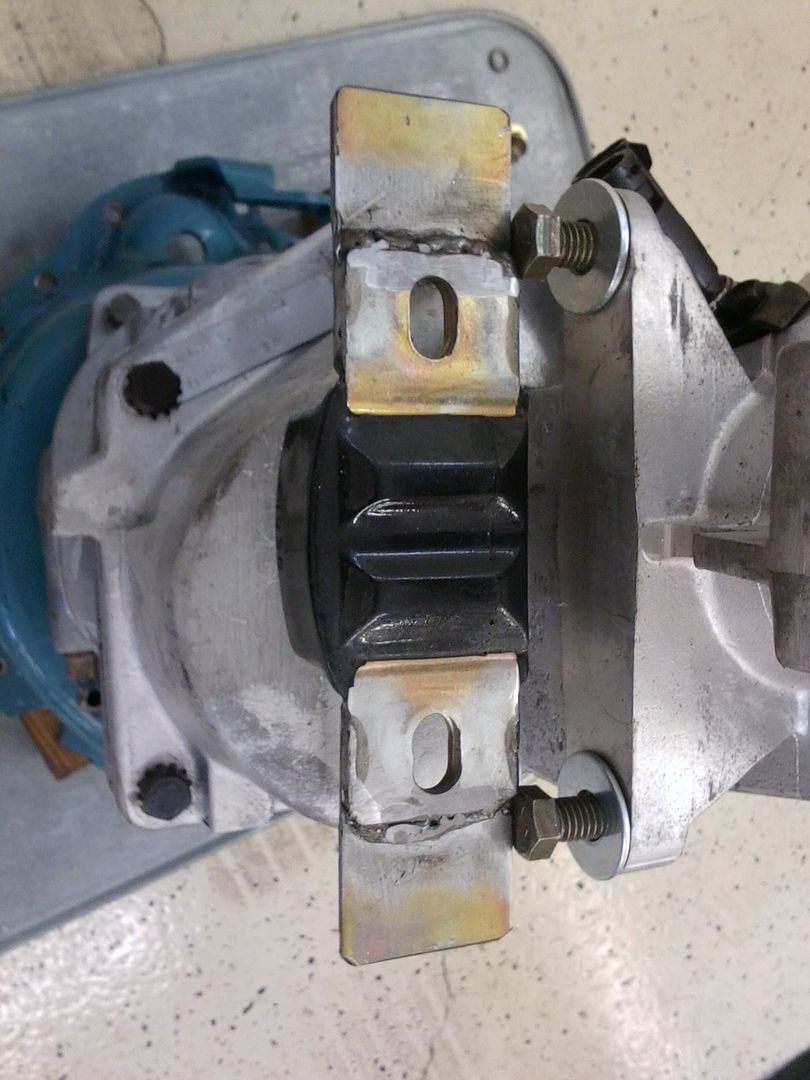

39 for trabs mount and mustang roller pilot from o'reilleys

37 fpr three quarts of redline at bradly auto parts (in indian trail, just outside charlotte. support your local speedshop, or no one else will. bradly sells most the stuff i need cheaper and quicker than mail order. also, those guys are a weath of knnowledge, and own pageland dragstrip. really, really great guys. go see them. now.)

and i traded my old spoiler for teh floorpan and crossmember stuff i needed.

so after selling my truck this morning to the same guy that bought my old track s10, i went on down to the shop. the only plans for today were to get the bellhousing, flywheel, clutch, etc out, and get the oil pan drpped out. i didnt expect a six hour fight, and having to remove the headers.

had to pull the header to head bolts out to allow the engine to rotate down enough for the lakewood bell to clear the trans tunnel. the TTI's were sitting on the t-bars, making it impossible. i also hat to pull them outward to clear the pan rails so i could removine it. the stage 8 locking header blts all came apart really easy. very, very glad i neversiexed all that. headers were off, and i got to looking at the TTI gasket on the passengers side verses the copper i have on the drivers side. the copper blocks roughly 25% of the exhaust port. holy crap. gonna have to fix that....

also found that my new idler arm is alread loose, my rag joint os loose, annd that i have some slagged wiring at the firewall bulkehead. thats just great.....

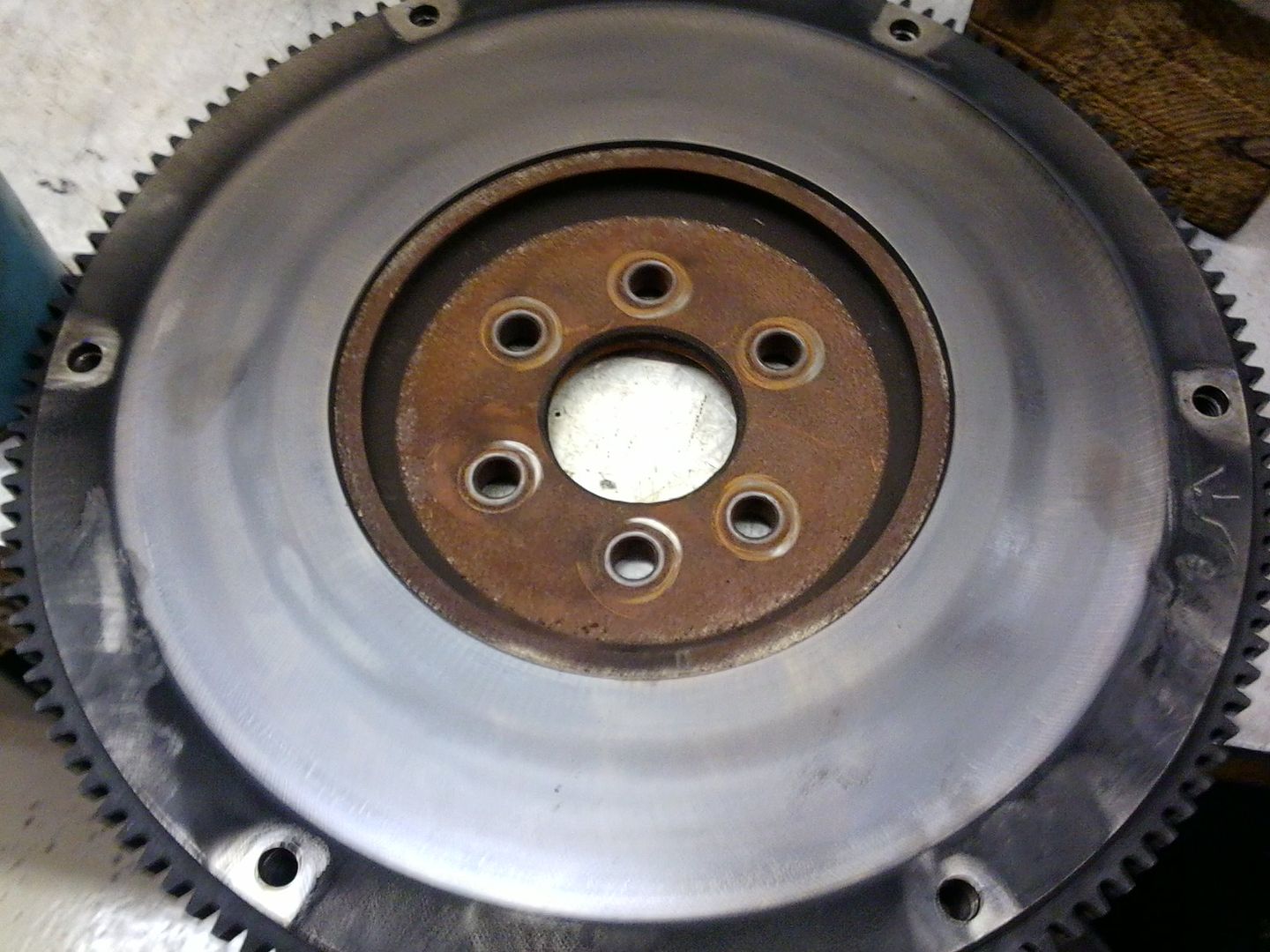

but the good news is its all out. bellhousing came down with a minimum of fuss after dropping the headers, amd the clutch/flywheel came out nice and easy. figured id show the durability of the spec stage 2+ after 10k miles, tons of dragstrip passes, hundreds of autocross runs, and thousands of powershifts. minimal wear. heck, teh flywheel still had surfacing marks on it....

i then went to drop the leaking oil pan. this is a nice, 7 quart kevco with custom fabbed pan rail reinforcements, trap doors, and a windage tray. great product, and i remember it being very cheap for all the features. fuit the car with no mods whatsoever, and ive NEVER experienced oil starvation.

getting it out was another story entirely. it was a nightmare, even with a lift. the reason is this:

what do you notice missing? look close....

those are ARP 12 point bolts. when i built the motor, i used POR15 engine painting kit, great, durable product as you can tell by the pictures previously. problem is, on the bottom of the engine, it filled ALL the notches on the bolts. making it impossible to remove them with a 12 point socket.

unless youre stubbron and have a big hammer.

i "tapped" the socket up on as many of the bolts as i could get to to get them loose. the ones that i couldnt get a socket on with an extension or hammer room, i sued some vice grips. took me 3 hours to remove the bolts. majjor, major buzzkill. but its obviously out, as i showed a picture of the inside. kinda spoiled the suprise, there....

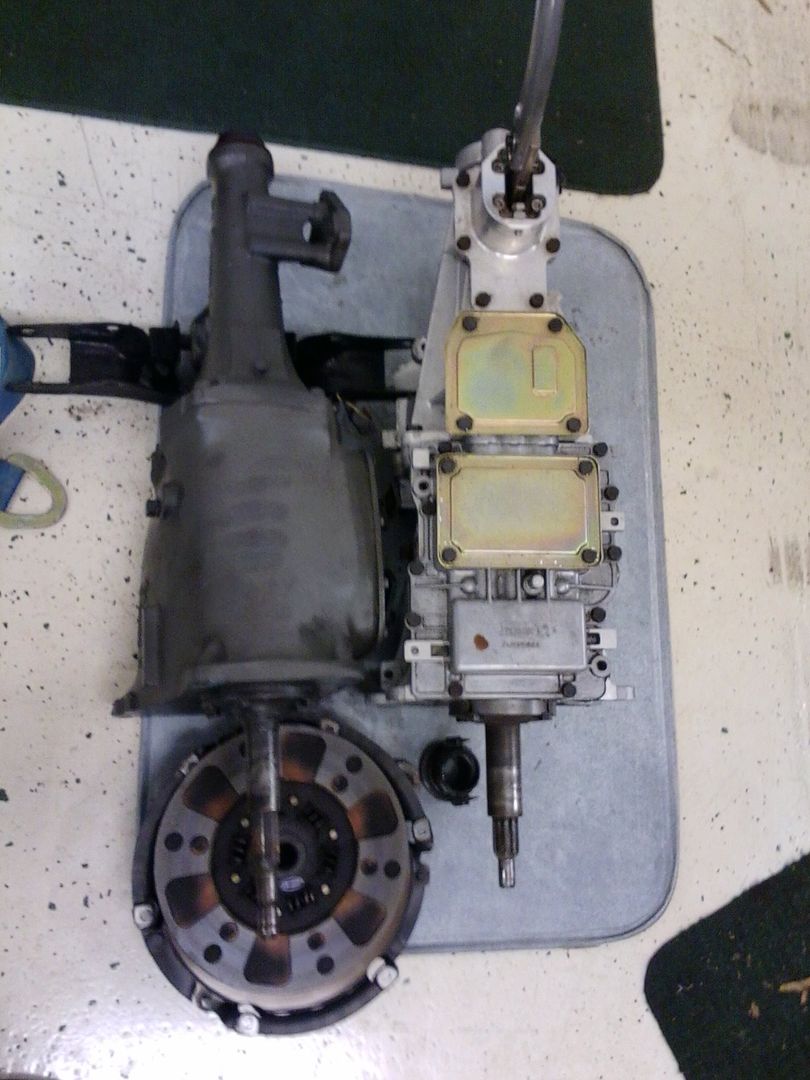

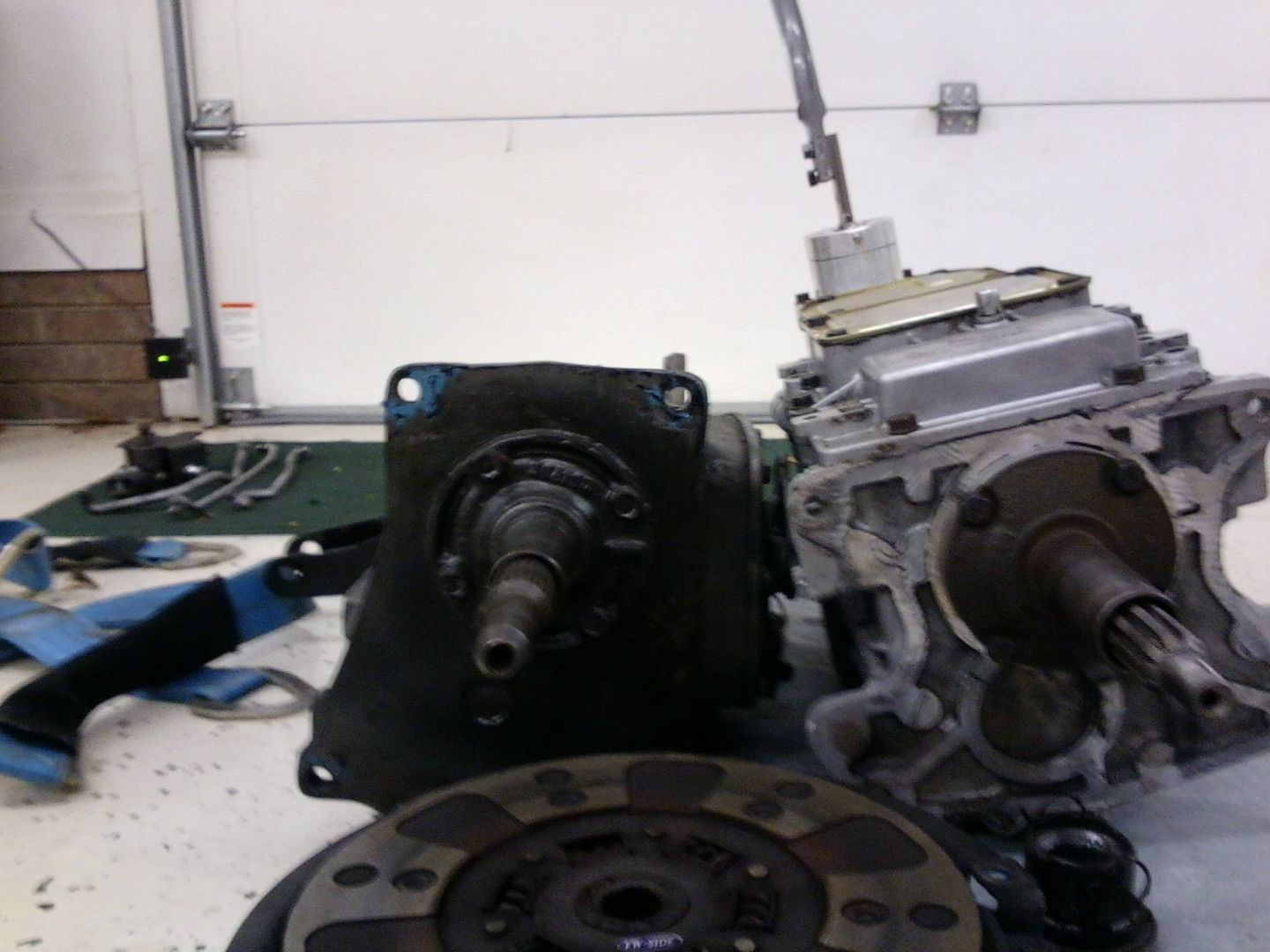

before i left for the night (jenn and mary asked for me to come home early for ribs and veggitales), i took some comparison pictures of the a833 vs the tremec trans. never saw any pictures showing the size difference, so i figured this might help someone....

i also dropped the flywheel at o'reilleys for a resurface.

so the plan for tomorrow is to get my new moroso 1 piece pan gasket up and in, the bellhousing modified, and the floor cut out. ould also like to get some clean up and organization going. i took the whole of next week off to do this swap, so im taking my time and trying to enjoy myself.

new budget total 7675.30

when i start my elcamino build, id like to get to almost this level, with a TOTAL budget of 10k. and a big block. and an automatic.

more tomorrow night. hopefully with a real camera instead of my cell phone.

yall have a good evening, and god bless. dont forget to be grateful for your blessings, and problems. cause all the priobles we have are problems of privelege, if you think about it. (if you cant figure that out, PM me and ill explain it)

michael