java230

UberDork

3/16/21 12:59 p.m.

Well I baby sat it a bit, making sure filament wasn't too hard for it to pull in.

I printed a thing, maybe even to help with the filament. Its a bearing roller for the filament. I happened to have a sleeve of 608 bearings right here and this was on thingverse.

Now learn me: why raft/no raft??

Mr_Asa

UltraDork

3/16/21 1:04 p.m.

java230 said:

Now learn me: why raft/no raft??

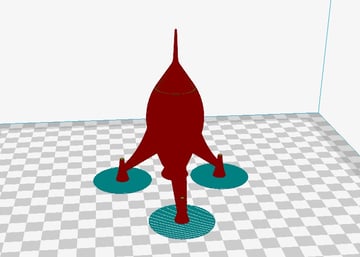

Rafts are dependent upon filament (ABS can warp real bad at the edges) and footprint of the model. If the print pops off the bed halfway through, try a raft.

Example of the footprint below, see how it could easily separate?

In reply to Mr_Asa :

That makes perfect sense, I have just been using whatever defaults so far, and they all rafted. But looking at it, the big flat bearning holders probably didnt need it?

Mr_Asa

UltraDork

3/16/21 1:38 p.m.

In reply to java230 :

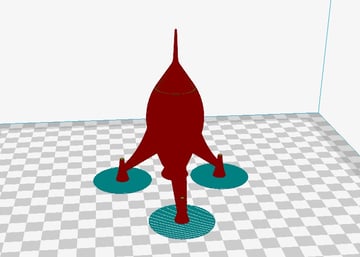

Yeah, I wouldn't have used one. I usually go with a skirt which basically prints an outline about 1" away from the part and gives you a chance to check your extruder is working properly and is leveled correctly before it starts printing.

You can see one here

AWSX1686 (Forum Supporter) said:

So I'm running into issues where mid print the extruder gear driving the filament into the bowden tube starts clicking because it's having trouble pushing more filament through I guess.

I just replaced the bowden tube because the old on got a bit clogged, so I just put on a new one with the Capricorn tube as recommended here.

Previously when it would be clicking like that if I pushed the filament in more myself that would help, but now that doesn't help. Any ideas?

So, when I took the nozzle off after this I had found that it clogged the bowden tube, even with the new capricorn tube. I then tried a fresh bowden tube and fresh nozzle and it clogged even faster this time. It almost seems like the bowden tube is getting to tight around where the tube clamp is because when I took them both apart after the clogs, they weren't just clogged at the end like I would think from heat or something.

Jerry

PowerDork

3/17/21 8:45 a.m.

A friend asked me to print something so he could use a ratchet to roll the windows in his caged car without the motors. Second revision worked perfectly. He sent a YouTube video.

Mr_Asa

UltraDork

3/17/21 10:26 a.m.

In reply to Jerry :

What filament did you use? Looks like a great usage for nylon

Jerry

PowerDork

3/17/21 3:43 p.m.

In reply to Mr_Asa :

Just PLA. I warned him heat would be his enemy, he said he was mainly testing the item he made in Tinkercad first. He said someone online would make it in metal for about $30.

Tom Suddard

Director of Marketing & Digital Assets

3/25/21 10:35 a.m.

Knocking out some prototyping for our Elva Sports Racer Project Car this morning. Still love my Ender 3!

is there any reason not to pay the extra $100 or so and get the larger Ender 5 ?

I've been getting along well with my 3 so far - even used it to print a replacement part for a kitchen doodad that I designed myself. Started playing with ABS last night - printed a test cube and must have been a little too eager to get it off the bed because I ripped it in half :) I did add a Pi running the Octopi OS and a webcam, mostly so I can be aware of squirrel nest action. But it's made for a decent workflow.

Tom Suddard

Director of Marketing & Digital Assets

3/25/21 12:42 p.m.

I'd skip the ABS and go right to PETG. It's nearly as heat resistant, stronger in most applications and way more UV resistant. Plus it prints super easily.

Mr_Asa

UltraDork

3/25/21 12:44 p.m.

In reply to Keith Tanner :

If it ripped in half you may not have had the extruder hot enough. Could have been experiencing delamination.

Also, I second the PETG suggestion. Only reason I'd go with ABS is for acetone smoothing.

I'll play with ABS a bit more because I have one complete spool and a few partials that I inherited. Thanks for the suggestion on PETG.

Extruder was at the default 240, I'll play with that. I suspect I happened to walk into the room right when the print finished and grabbed it - does it need to cool? I do have an enclosure around the printer.

Well my card reader that came with the Ender died... I keep forgetting to grab a new one.

However the bearing roller/roll holder works great!

Mr_Asa

UltraDork

3/25/21 3:04 p.m.

In reply to Keith Tanner :

I've found that generally the more it cools, the easier it is to remove from the bed. Different coefficients of expansion and all that.

Yeah, looking at the piece it looks really good other than the broken part :) It snapped right at the base, just a few layers off the bed. I think I'll try a do-over and a little more patience before I change any settings.

java230 said:

Well my card reader that came with the Ender died... I keep forgetting to grab a new one.

However the bearing roller/roll holder works great!

Spend $25-45 on a Pi, load this on it and you'll never need the card reader again :) I do everything through a browser interface on octopi.local. It does not need the internet, just a local network. The camera was $30 plus another $3 for a longer cord.

One thing I've learned with my Ender 3 is that it's like a Barbie doll, an AR-15, or a Civic: The intitial purchase is just a down payment. The real money is in the mods.

I pretty much doubled the cost of my K40 laser in mods. But it got me a device that's pretty darn close to a Glowforge for half the price by the time I was done!

Cooling will help get it off the bed with less force, but won't help strengthen the printed part.

Mr_Asa

UltraDork

3/25/21 6:33 p.m.

Keith Tanner said:

Yeah, looking at the piece it looks really good other than the broken part :) It snapped right at the base, just a few layers off the bed. I think I'll try a do-over and a little more patience before I change any settings.

The really great thing about ABS is you can just eye dropper some acetone on the two surfaces, clamp 'em together (not too much force) and let them sit overnight for a complete piece.

I'm abusing the rest of it and I can't seem to get it to come apart. Haven't broken out the vise yet.

Printed another ABS test cube, it came out very nicely and strong. Did an overnight print with a few doohickeys including some centering jigs that are long and thin and it all turned out very well on ABS. Some very slight warping on the longest jig - maybe 0.010" high in the middle of a 5" long piece, measured by eyeball - but well within acceptable parameters. Printing on all the defaults with a bit of hairspray on the glass bed.

Next I'll try some PETG.

figured out how to print a quarter scale brake caliper complete with internal passages. We'll find out in 47 hours if I can print one full size.