This is not an epic Mazdeuce-style build, or a stunning Jumper K Balls piece of work. But it was fun, so I thought I'd share. You've seen rig shots before. They're a staple of automotive photography, and they look awesome.

But they're a pain in the patootie to shoot. You have to hang the camera off the car with a collection of pipes and suction cups. You take a long exposure at walking speed with the car just rolling, then do a little editing to get the pipes out of the shot - which isn't as bad as it sounds. The pipe is set up to be above the camera so it doesn't cover up the car, only the sky. But every shot is different and the amount of rigging can get out of control. It can also be very expensive. Here's the rig for the above shot.  I've worked with a lot of photographers doing shots of various kinds, but most often I work with my friend Travis. He does a lot of work for Koni - the picture above is used on a bunch of their advertising. That's me behind the wheel

I've worked with a lot of photographers doing shots of various kinds, but most often I work with my friend Travis. He does a lot of work for Koni - the picture above is used on a bunch of their advertising. That's me behind the wheel ![]() But Travis doesn't have a lot of money to throw at his rig. He chose to invest in good suction cups and mounts and uses lengths of thick walled conduit joined by compression fittings as the actual pole. This is heavy, limits his ultimate reach and has a distressing level of jank. This is a 15' total length in the picture, that's as long as he can go.

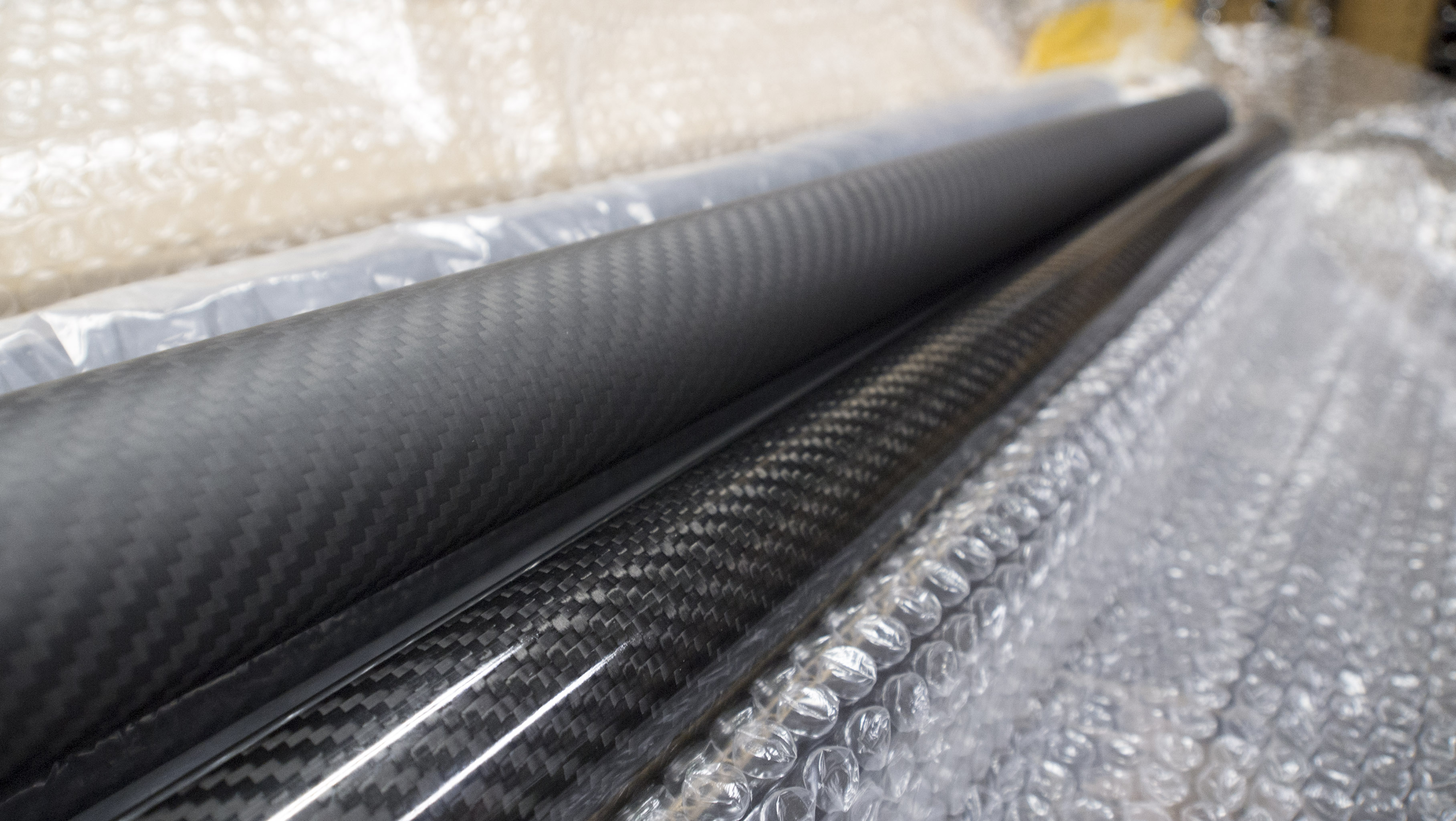

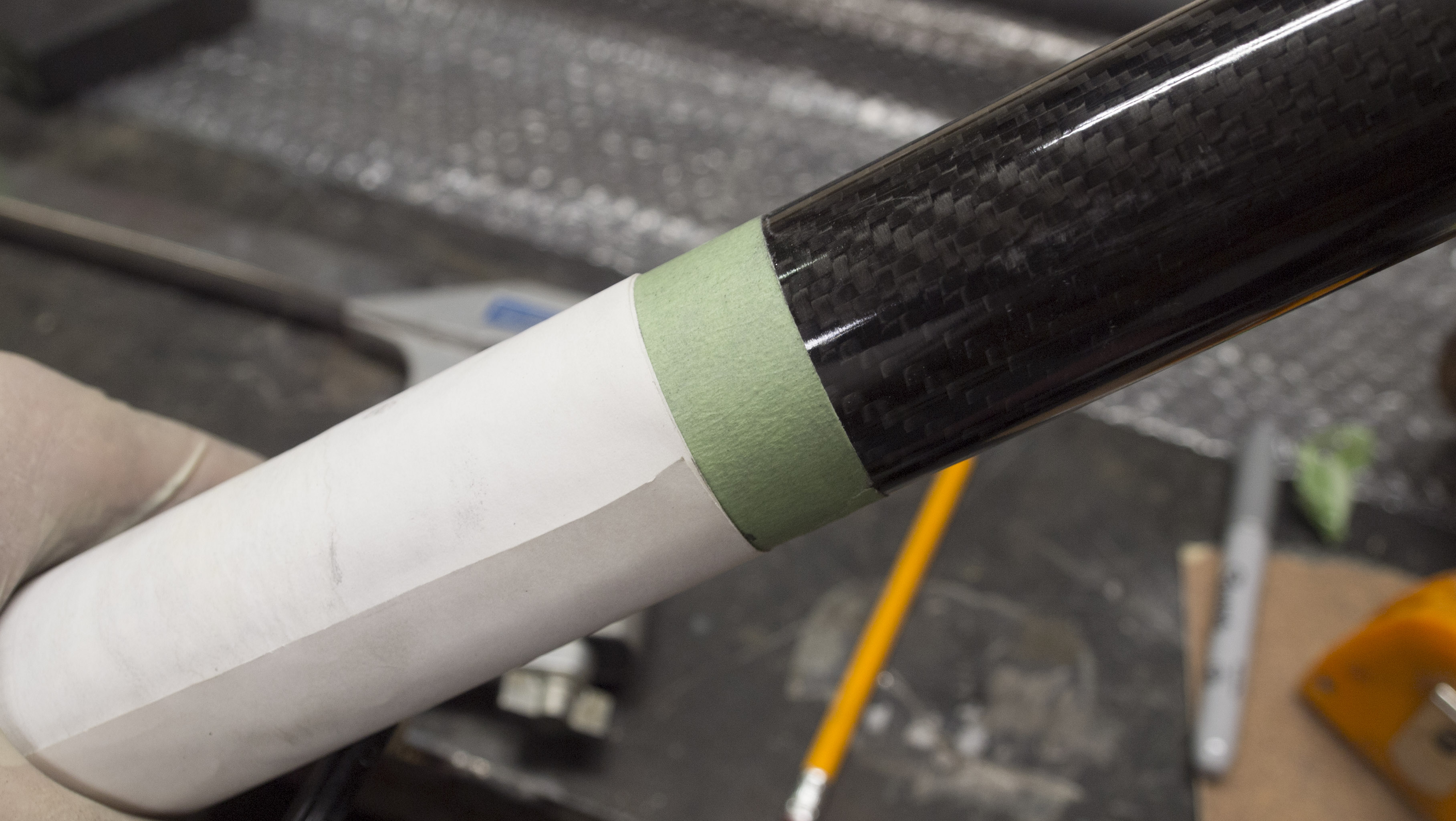

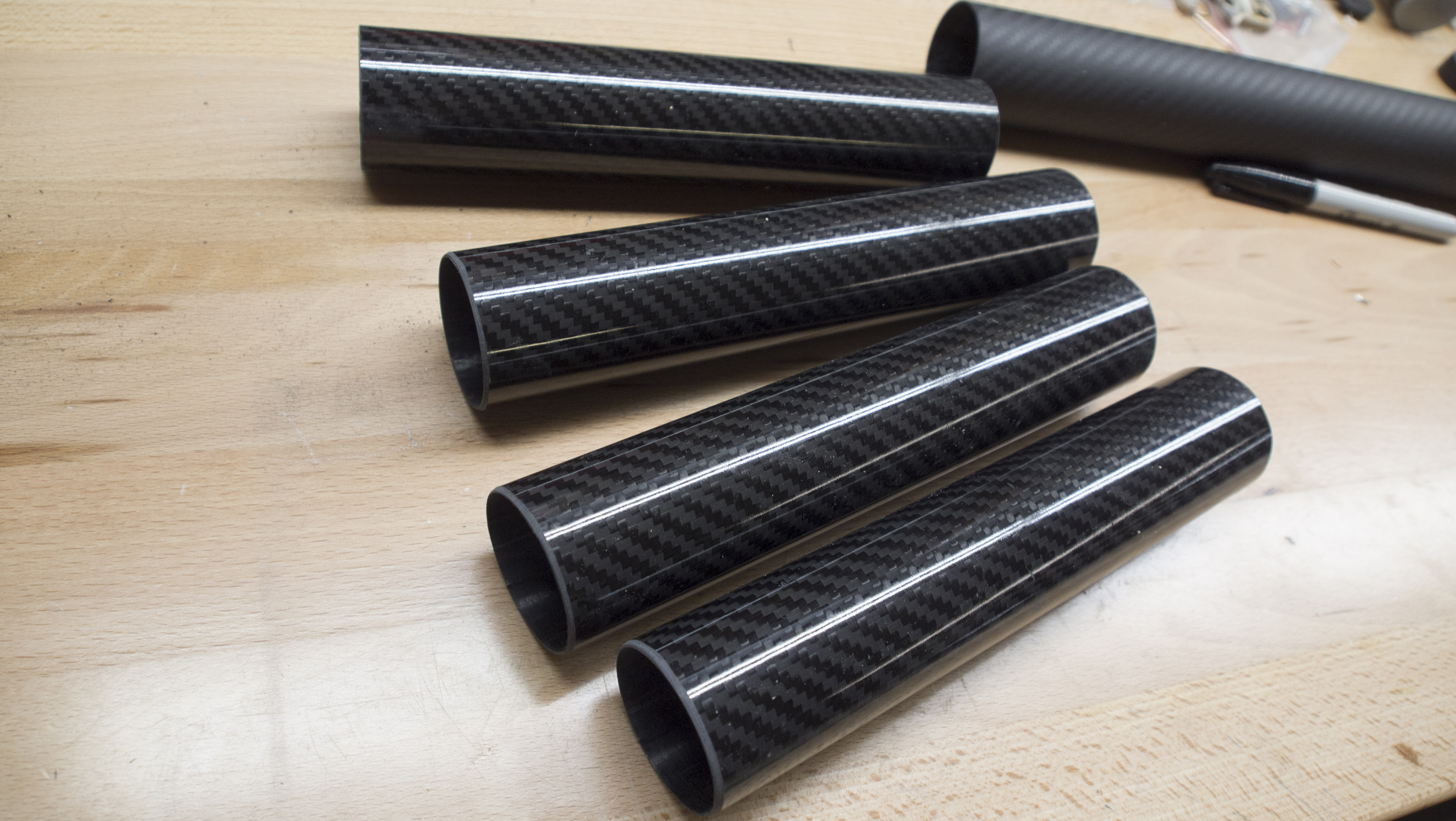

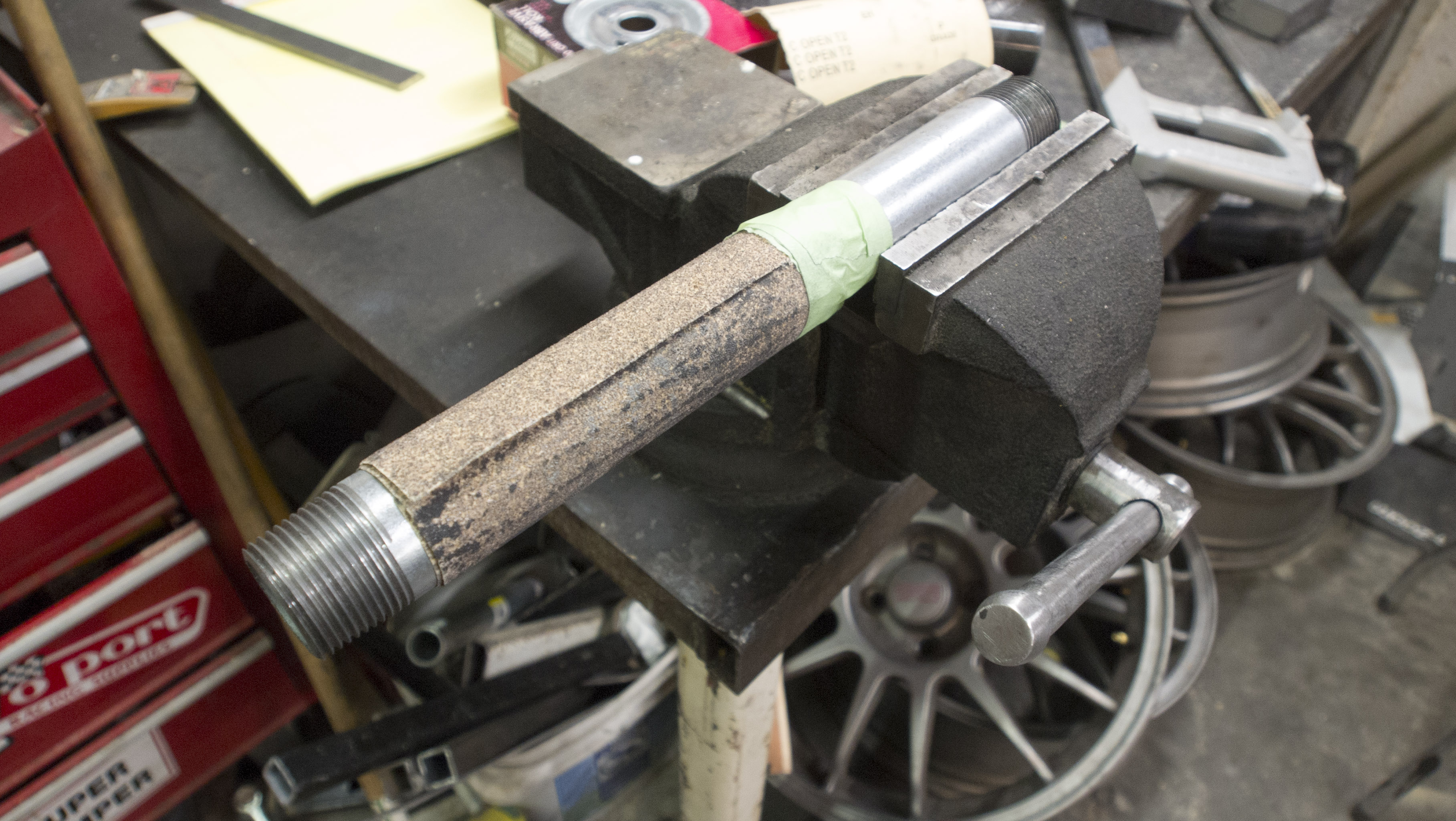

But Travis doesn't have a lot of money to throw at his rig. He chose to invest in good suction cups and mounts and uses lengths of thick walled conduit joined by compression fittings as the actual pole. This is heavy, limits his ultimate reach and has a distressing level of jank. This is a 15' total length in the picture, that's as long as he can go.  You can get carbon poles, but they're very expensive. I figured I could probably put something together for Travis that was better than his current setup, and a project was born. Warning, I took a lot of pictures.

You can get carbon poles, but they're very expensive. I figured I could probably put something together for Travis that was better than his current setup, and a project was born. Warning, I took a lot of pictures.

It's creepy light, by the way. Under 4 lbs.

It's creepy light, by the way. Under 4 lbs.