In reply to bluej:

He said inch, the alignment sheet says degree. Still one degree per side is a ton

In reply to bluej:

He said inch, the alignment sheet says degree. Still one degree per side is a ton

So, the trailing arm mounts are bolted to the car, correct? If it needs to move out you should be able to shim it to a position where the toe will be acceptable- then you can weld the shims right onto your reinforcement plates so the trailing arm bolts up like normal. Maybe there's something I'm not seeing that would prevent that, but frame rack time isn't cheap.

It was more than a degree. I saw it personally. I would have guessed two inches just on a visual look...

Well it looks like this project is over before it was completed.

I took the car to a collision/frame shop to have them look it over. I was hoping they would just be able to put it on their frame machine and pull it straight, but it seems the damage is far more extensive than I or anyone else realized. They said the PS rocker needs to be completely cut out and replaced, as well as the sidemember/crossmember. Their estimate was about $2,500.

I sent the estimate and some pictures to other collision shops, and their responses didn't make me feel any better. Two shops told me outright that they wouldn't even put the car on their machine to check it out, as it was so far beyond what they would consider repairing. Another shop that's familiar with E36s said the first estimate is accurate, and that the car is pretty well berkeleyed. I could pay them $250 to put it on their machine, but the answer wouldn't change. The car has serious problems that can't be fixed with a simple pull job.

I'm now in the unenviable position where I just got done completely rebuilding a car only to find out the chassis is junk. I don't think it would be wise to try and repair the frame, as who knows what else they will find when they start really opening things up. My only option is to try and move everything over to another chassis. I'm pretty sure I won't be able to find any M3s within my now tiny budget, so I'm left to consider which non-M car I should start looking for. 318, 325, or 328? If I'm going to swap over the motor, I assume a 328 would be the best place to start. But what about all the chassis stuff? I have brand new M3 control arms, and a completely rebuilt rear end. Can all of that be transferred to a non-M chassis?

I'm in shock right now, and my brain is going blank. It's 10 am and I have a strange urge to drink myself into oblivion, because I can't comprehend the work and headaches ahead of me. I just want to give up and quit, because I don't know how I'm going to handle this. So much time and effort down the drain, only to have less than I started with.

For what it's worth, if you sent my RX7 to a frame shop you'd get a quote for 3x that- this might mean you need another chassis if you want everything to be straight and nice, but not that what you have is unworkable. You can move mounting points, slot holes, make custom arms, berkeleying put a 4 link and live axle back there if you want to. Doesn't mean you have to throw it away.

Crap, well that's a E36 M3 sandwich.

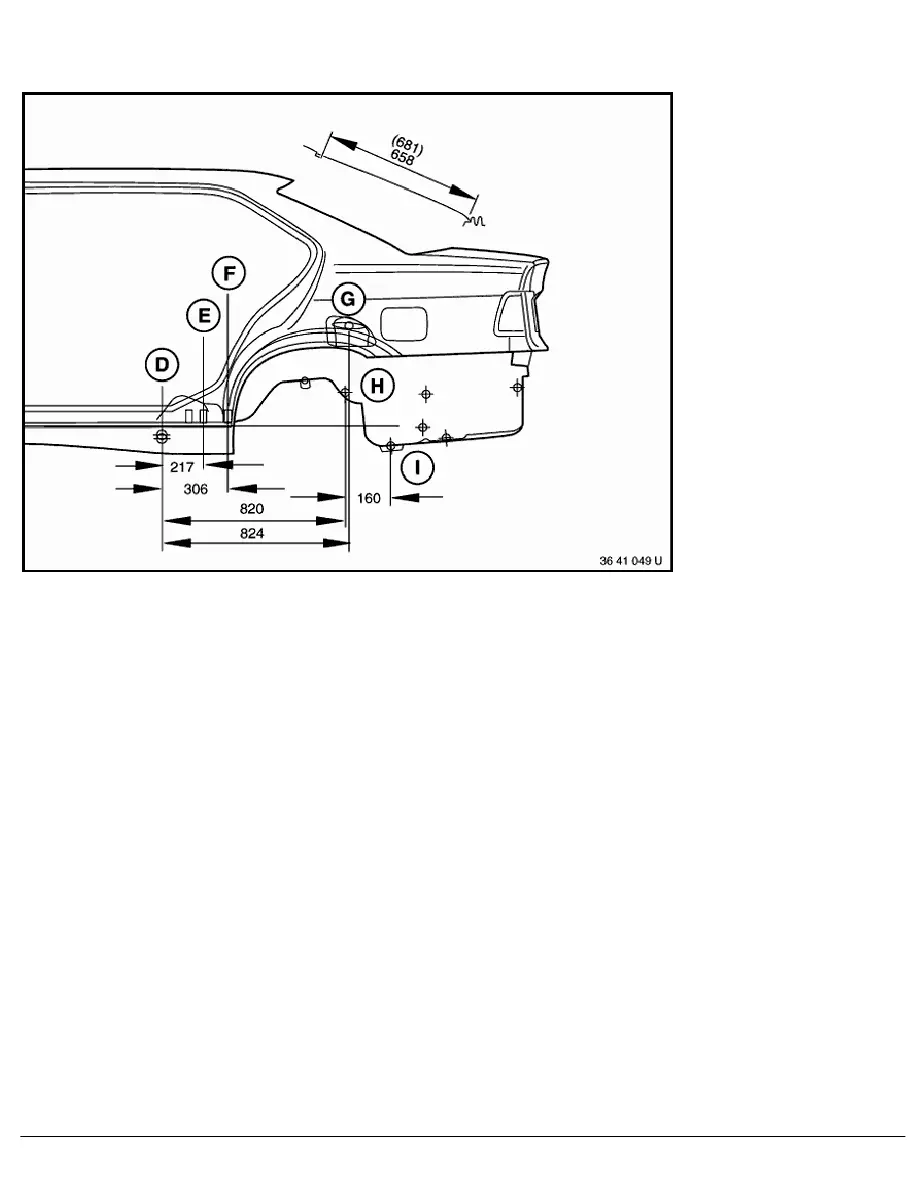

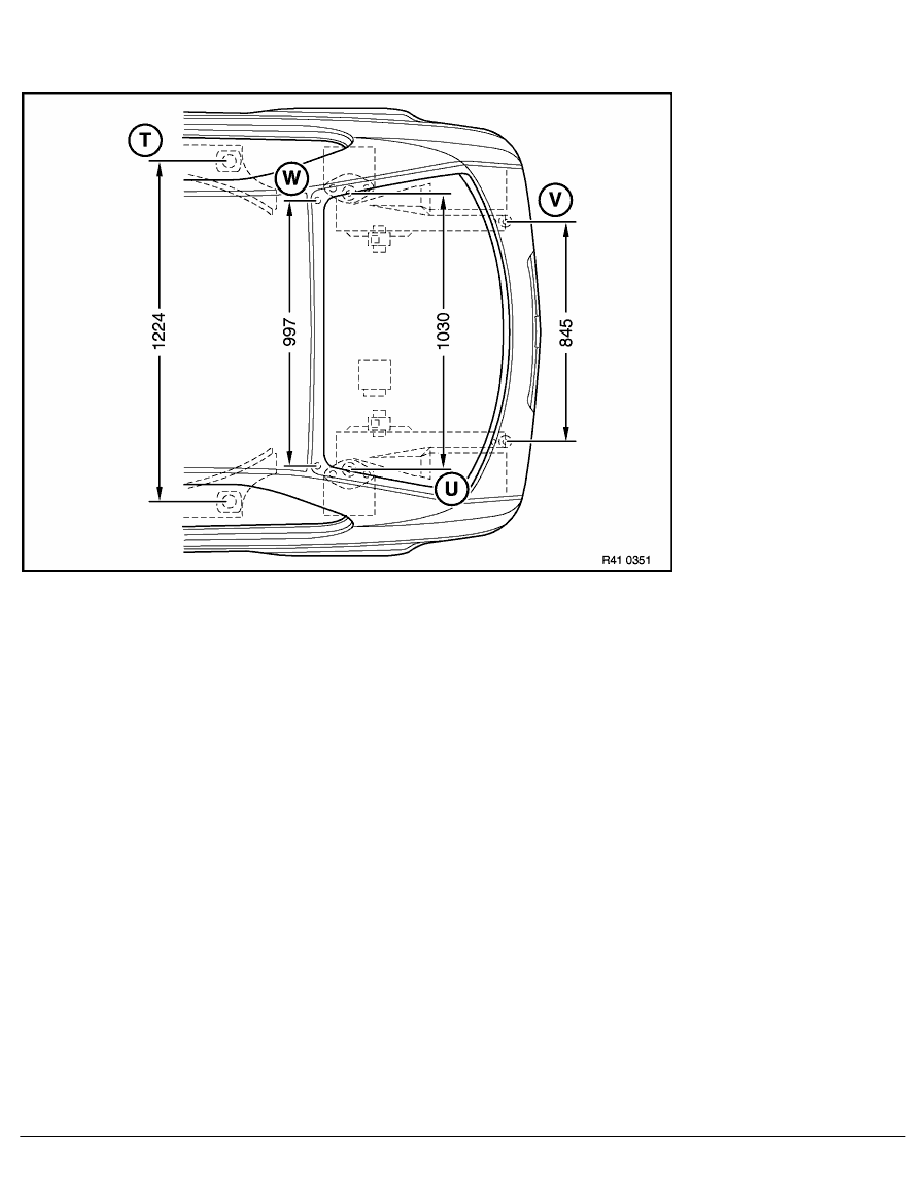

OK, this is a rally cross car. It's never going to be perfect and it's going to get beat to hell anyway. Can you get a mark up on the frame alignment sheet (like below) showing what is out in what direction?

Go and look at some LeMons and Chump car builds and repairs. People have done amazing things with bent cars using trees, chains, trucks and hydraulic rams. I'm sure you and some of the local guys can pund/bash/hit/cut/weld back close enough to get an alingment that's good enough if ugly for rally cross.

I'm with the guys above, you've already done all that work. Cut, weld, chains, trees, hydraulics, trucks, just go after it. Don't throw in the towel because of this. You got it, it will just take a little more time and effort.

I hear what you guys are saying, but would you still feel the same way if the bill ends up being $3,500? The last shop that I called mentioned seeing a lot of corrosion, so that's an issue as well. On Craigslist within 50 miles there are multiple suitable E36 candidates for less than $1000. I'm not looking for perfection, but I do want this to be more than just a race car that I drive one a month to and from events. I was planning on keeping this car for a long time, and would prefer to not be racing something that's been hacked apart multiple times.

95maxrider wrote: I hear what you guys are saying, but would you still feel the same way if the bill ends up being $3,500? The last shop that I called mentioned seeing a lot of corrosion, so that's an issue as well. On Craigslist within 50 miles there are multiple suitable E36 candidates for less than $1000. I'm not looking for perfection, but I do want this to be more than just a race car that I drive one a month to and from events. I was planning on keeping this car for a long time, and would prefer to not be racing something that's been hacked apart multiple times.

Nope, I'm not talking paying a shop, I'm thinking your total out of pocket costs for this should be a case of beer and a few pizza's. I've been a part of some epic bodges in the past cutting and welding dead cars back to straight. People have skill and I'm sure you'll find volunteers here and on other forums.

Nobody is saying have a shop fix the car. They are suggesting low tech low budget methods of getting it close to right and call it good.

For my type of use I would just bang with a hammer until everything lined up (That is what I did for my rallyx miata but it was not suspension) However given your projected use I would look at a donor shell for your car.

Invite a bunch of people over and with a 2 car garage you could likely have it 90% swapped in a day.

How much will the left rear move if you adjust it to zero toe? I have seen trailing arm arrangements where the wheelbase changes visibly as you adjust toe. I'm not sure those printouts tell us enough when the left rear probably has all sorts of wonky adjustment going on to make it match the right.

As I suggested last night, there are a million cheap e36s on craigslist. According to Jim, pretty much EVERYTHING from your M3 will bolt up directly to a regular e36 (though you'd want to do the chassis reinforcements that non-M cars don't have). So go find one with a blown motor for $500, buy it and we'll swap everything over to it - suspension, drivetrain, interior, etc. Hell, I bet your insurance will even be cheaper with a non-M car. A few of us get together for a weekend and can have it done.

Or find a running regular e36, and run it as-is while you slowly swap everything over. You don't have to do it all at once....a stock e36 is plenty competitive as we've seen locally already. Race it and build it as you have time. At least you already have parts. Trying to to the billion upgrades you were doing all at once was way too much stress and rushing. Drive it stock and mod as time allows. That's what most of us do.

THe ETA boys have been doing precisely that in the last few weeks - movign all their good stuff from the old e30 to the new one. It's a hassle, but at least your car isn't coated with clay and mud yet.

Yeah, it sucks. But it's the best of possible options IMO unless we go for a ghetto fix (comealong and a tree, etc). Though that said, if the frame is toast anyhow, might as well try that first and see if it works.

Just in the immediate vicinity:

$800 http://washingtondc.craigslist.org/mld/cto/5617212126.html

$750 http://washingtondc.craigslist.org/mld/cto/5611681283.html

$350 with bad engine http://washingtondc.craigslist.org/doc/cto/5586110652.html

$2K for one that looks nice http://washingtondc.craigslist.org/mld/cto/5574293604.html

alternately, I have a comealong and a big-ass tree in my yard.

Oh man. That really is awful. I guess in re reading this thread all signs are to a bad passenger side hit (b pillar re weld, trunk passenger side trunk damage , rust on one shock pillar only). I say get a cheap e36 and slowly swap over. You can part out doors and stuff and make some money back on the shell I imagine. Chin up! Just think of the stories you can say about your car when it's done!

Also looking at the e36 trailing arm design, I almost feel like maybe you could just bend the trailing arm slightly to obtain correct toe. Basically slot it on the outside and give it a couple good smacks with a sledge to make the curve in the RTA a "little bit more straight" to push the toe out. Then just re-weld the slot to get the RTA back up to strength.

I mean, the worst that can happen is that you ruin a trailing arm, right?

Oh man that really sucks to hear!

But if this is the bad news that could drive you to drinking yourself into next month, you've got a good life!

If the car is massively tweaked and has rust, seems like the best way to go, as has been said, is to buy another e36 and start swapping stuff over.

You mentioned not having much money - selling the stuff you won't need off of the "new" car will likely net you a profit.

[QUOTE=Pyropete82;29270376]Private sale or dealer? No recourse to sue I assume...?[/QUOTE]

Private seller who has since died, so yeah, no recourse.

So I've tried dealing with another frame shop to no avail. The shop said their machine isn't accurate enough to fix the problem, even before really inspecting it, so that was a waste of time.

In the mean time, I've been talking with one of the guys I race with (Jeremy) who also races an E36, and he had an interesting idea I wanted to run by everyone. His idea was to weld one larger plates over the existing ones that go over the pocket. Shown below (plates are towards bottom of picture and have the four adjustment/bolt slots.

After we weld new plates in, we would make the slots longer to allow them more room to adjust the toe back to spec. My only concern about that is how much room the bushings have inside the pocket. If I can adjust the tailing arms out of their "normal" range and back into spec, will that extra adjustment cause the bushings to bind? Does anyone know how much clearance there is on either side of the bushing inside the pocket? Can the pocket be forcefully spread apart to make room for the extra adjustment? Any advice would be greatly appreciated!

I think I said that in the second post on this page, so... yes do it! Why do you think you'll have binding issues? You're moving the bushing back to where it's supposed to be, if anything this should reduce existing binding issues.

¯\_(ツ)_/¯ wrote: I think I said that in the second post on this page, so... yes do it! Why do you think you'll have binding issues? You're moving the bushing back to where it's supposed to be, if anything this should reduce existing binding issues.

I didn't quite grasp what you were saying there, my bad. I'm not sure if shim is the best description, but I think we're on the same page now :)

So apparently there is a guy on Instagram who makes new trailing arm brackets from scratch that have a lot of extra adjustability built in to get a lot more toe out. Here are some screen grabs of his work since you can't copy the image address...

$150 shipped and they come powder coated black. Apparently they're mainly for stance guys with up to -9.5* camber, who need to get rid of excessive toe in, which is more or less my problem. I'm thinking of picking them up, what do you guys think?

You'll need to log in to post.