I've been looking into some of the funky versions of ICE and wondering why we don't see them in mass produced cars.

1. Opposed piston two stroke engines with superchargers. Ford is researching opposed piston gasoline engines near 50% thermal efficiency. It seems like this design would be relatively simple and that you could make large displacement from a small number of cylinders and thus simplify. Like a 2.0 liter, two piston, single cylinder would seem doable on NVH grounds because there would be twice as many power strokes and boxer layouts are usually smooth (I think though I'm not sure this applies to opposed layouts). With a supercharger there would seem to be no need to mix fuel and lubrication (supercharger blows directly through the intake, meaning the piston doesn't need to suck intake charge in or compress the crankcase).

2. DUHC engines. The general drawback of DOHC engines is that they're externally huge and heavy for any given displacement (hence LS swaps having basically no weight or packaging penalties for most originally 4 cylinder cars). The general drawback of pushrod engines is that you have difficulty independently varying intake and exhaust timing for emissions purposes. Why not Double Underhead Cams like they did in old Triumph motorcycles? This would be very awkward on a V engine, but on an inline engine or a boxer, why not drive the cams directly off the crank (one intake and one exhaust for an inline engine, two intakes and two exhausts for a boxer) and, aside from a fatter lower block, enjoy efficient OHV packaging, easier oiling systems and a tiny cylinder head to go along with your independent cam timing?

3. Very long stroke engines. Back in the early 20th century, most engines were very, very under square. The original Duesenberg Straight Eight, for example, was 2.875 inch bore and a 5 inch stroke for a total displacement of 4.3L. The desire for bigger valves and higher redlines drove the engines oversquare in the 1950s. However, with emissions and efficiency being so important today, along with vastly better bottom ends that can handle long strokes with tolerably high redlines, why aren't we seeing these extremely undersquare engines returning? A very long stroke offers a much greater expansion ration for each combustion event and the smaller bore for any given displacement means that most of the heat (near TDC) will be exposed to a smaller surface area and thus waste less energy through the cooling system. Tiny combustion chambers would seem to make it easier to minimize poor combustion zones like top ring lands, improving emissions. Finally, very long stroke engines would seem to be tailor made for Atkinson cycle cam timing.

My bet is emissions, honestly. Seems to be the driving force behind a lot of stuff these days.

In reply to DaewooOfDeath :

Welcome back!

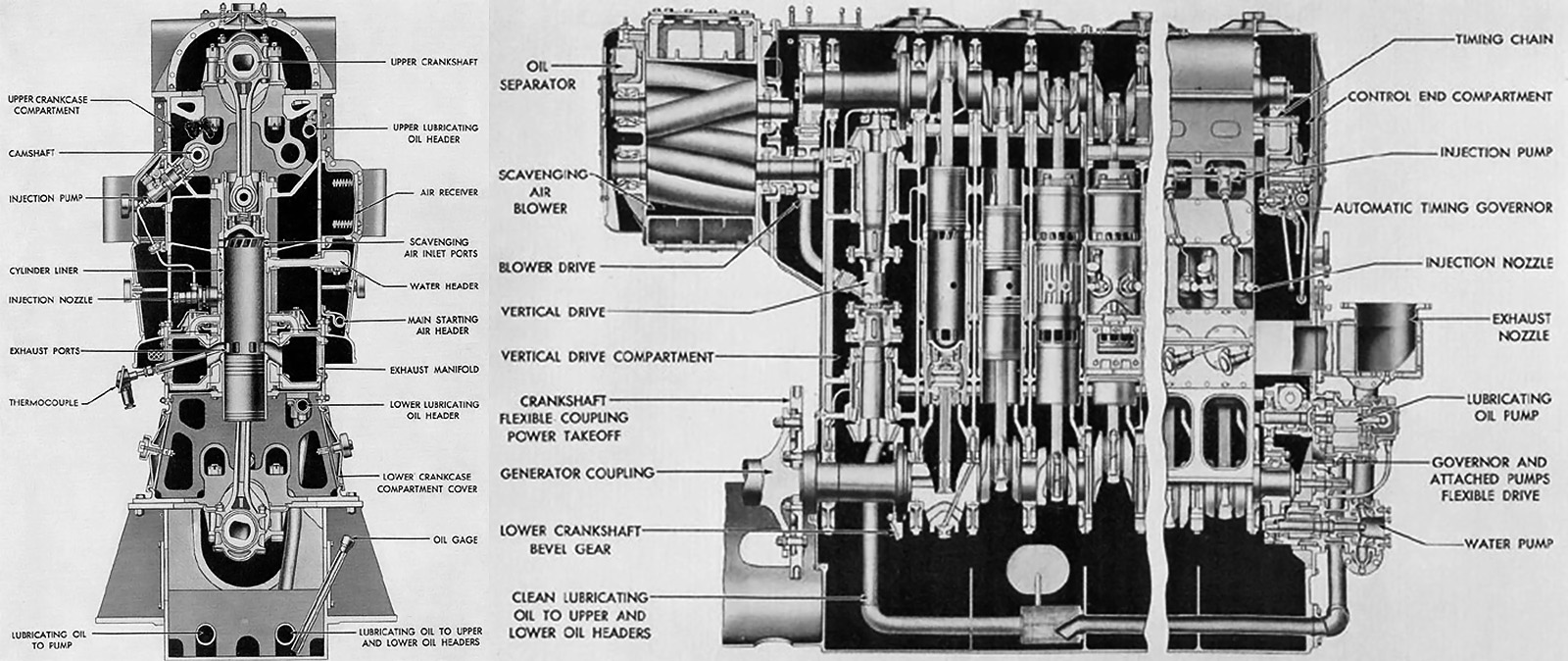

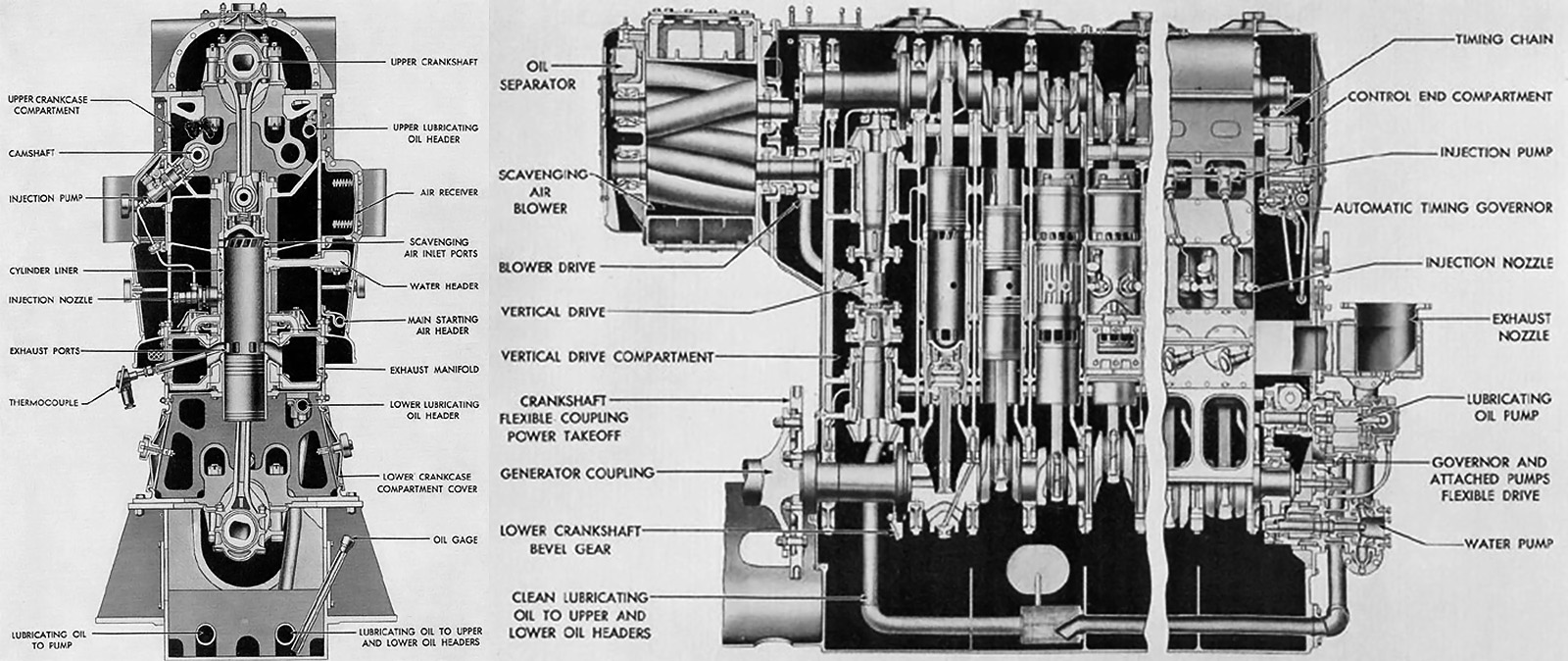

There was some recent discussion in the railroad thread about a vertically-opposed diesel in Fairbanks-Morse locomotives, and their propensity to catch fire once they had some miles(and lack of maintenance) on them. I think modern engineering could probably negate most of that, and certainly proper maintenance would help.

In reply to Pete Gossett (Forum Supporter) :

Thanks Pete!

I'd love some information about those Fairbanks-Morse engines if you have a link.

In response to #1, 2 strokes are dirty. (also, awesome, but like the rotary, little place for them in the modern world.

#3, Look at the Nissan QR25. They tried what is an astronomical stroke to bore for modern engines. They have some potential, but are pretty terrible engines (note, this is largely due to ingesting cats enema-style through the exhaust valves). Nobody else seems to be playing the long stroke game anymore. Give me an early FZR600 any day, or a 351 W.

#2, I guess, maybe there is a bizarro world where humanity took the fork in the road to develop cam in block engines, but I believe we went down this path because you could bolt a better head on a cam in block engine without having to re-engineer the whole engine.

These are, of course, all opinion, and worth exactly the price paid

Here's a BMC with a K100 head.

NickD

UltimaDork

10/31/20 11:14 a.m.

In reply to DaewooOfDeath :

Fairbanks-Morse built, actually still builds, big 2-stroke supercharged vertically opposed piston diesel engines. They built them for WWII submarines, had a brief and unsuccessful foray into the railroad industry, and then have continued to build them for marine usage and power generation. Fairbanks-Morse is actually a big consultant on the Achates Power opposed-piston engine that Ford is looking into, which makes sense.

They were fuel efficient, powerful for their time (F-M was making 2400hp out of a 12 pistons when competitors were making 1600hp out of 16) but their uniqueness made them a hard sell. Maintenance crews didn't understand them and struggled to work on them. Also, as a result of being an adapted marine engine, they tended to run hot in the limited cooling system aboard of a locomotive. When they got old and tired, if you idled them in cold temperatures for extended periods of time, then some of the cylinders would stop firing and they would leak fuel down from the upper cylinders into the exhaust manifolds and muffler, then you would rev them up and they would shoot 4-6' fireballs out the stacks as they lit off. Also, the oil seals would start leaking, and at first they would carbon up the exhaust, so you'd load them up and they'd blow chunks of flaming carbon (think baseball size) everywhere. As the oil seals got worse, they would suck oil and the engine would go into a runaway condition.

That being said, I think the 2-stroke OP design does have a lot of advantages (and they sound sweeet) and I'd love to see that Achates Power engine become reality.

In reply to DaewooOfDeath :

Some modern engines ARE extremely undersquare. The Honda L15 is one of my favorite examples because it's so common. Oversquare is mainly an effort to get more valve area. Modern think is undersquare (and zero-short-turn-radius intake ports) for combustion efficiency and make up the VE losses with a turbo, and run at stoich under boost.

Dusterbd13-michael (Forum Supporter) said:

My bet is emissions, honestly. Seems to be the driving force behind a lot of stuff these days.

It's been the driving force since the 1960s wen we realized, hey, air should not be chewy.

All "new developments" are simply a result of technologies maturing. Thre was the time before catalysts, and the time before EFI, and the time before variable cam timing, and the time before direct injection.

Heck, it's amazing how electric power steering proliferated from a rarity to 100% saturation in what seems like one or two product cycles.

NickD

UltimaDork

10/31/20 11:21 a.m.

We had a thread on the Achates Power 2.7L 3-cylinder, 6-piston engine. 270hp/460lb-ft in a 2.7L gasoline engine is stout, and then 47mpg supposedly.

https://grassrootsmotorsports.com/forum/grm/have-we-talked-about-the-achates-power-27l/162830/page1/

In regards to #3, the expansion ratio is the same thing as compression ratio, which can be set to "whatever" even with a shorter stroke. Longer stroke gives smaller wetted area in the head for the same expansion ratio, which does give better emissions.

Those old old super long stroke engines also had steel pistons, IIRC, which are limited in diameter by their ability to get rid of heat to the cylinder walls. The change from super long strokes came at the same time as working out good aluminum pistons, didn't it?

matthewmcl (Forum Supporter) said:

In regards to #3, the expansion ratio is the same thing as compression ratio, which can be set to "whatever" even with a shorter stroke. Longer stroke gives smaller wetted area in the head for the same expansion ratio, which does give better emissions.

Those old old super long stroke engines also had steel pistons, IIRC, which are limited in diameter by their ability to get rid of heat to the cylinder walls. The change from super long strokes came at the same time as working out good aluminum pistons, didn't it?

Long strokes mean you get a more spherical combustion chamber for a given compression ratio, since no matter what the power stroke starts at TDC.. This means the maximum distance the flame front has to travel from the spark plug is minimized, meaning rapid combustion, meaning high resistance to detonation, also meaning minimal ignition advance needed for MBT timing which means less negative work needed, so maximum efficiency.

I hope to see steel pistons making a comeback. They are more thermally stable dimensionally, so one could run the clearances tighter. And no worries of melting one from high combustion temperatures.

Dual under head engines are not limited to Triumph motorcycle. Riley made a lot of them in 4 and 6 cylinders, and Talbot did it in France. Long strokes too. The valve area needed led to big bores, and power is related to piston area as well as displacement. The only thing that kept the long stroke around for so many years was bore sized taxation in most of the world.

DaewooOfDeath said:

I've been looking into some of the funky versions of ICE and wondering why we don't see them in mass produced cars.

2. DUHC engines. The general drawback of DOHC engines is that they're externally huge and heavy for any given displacement (hence LS swaps having basically no weight or packaging penalties for most originally 4 cylinder cars). The general drawback of pushrod engines is that you have difficulty independently varying intake and exhaust timing for emissions purposes. Why not Double Underhead Cams like they did in old Triumph motorcycles? This would be very awkward on a V engine, but on an inline engine or a boxer, why not drive the cams directly off the crank (one intake and one exhaust for an inline engine, two intakes and two exhausts for a boxer) and, aside from a fatter lower block, enjoy efficient OHV packaging, easier oiling systems and a tiny cylinder head to go along with your independent cam timing?

I think the future of production engines will include a method of actuating the valves that doesn't require camshafts at all, whether it may be pneumatic, hydraulic or maybe electric. It eliminates the space issues of both OHC and cam in block, and allows for continuously variable valve timing.

In reply to stuart in mn :

Like fusion, that kind of valve train is 20 years off. Just like it was 20 years ago.

Does Koenigsegg use that tech on road cars or are they perpetually in development? There's a video of a test unit installed on volvo(?) that was pretty amazing too.

In reply to buzzboy :

Forgive me for not considering Koenigsegg as anything significant for automotive tech. Development cars were around 20 years ago that had the tech- those I saw, and a friend of mine was working on it. Lots of promise. Then it was dropped. And nobody has put it into serious serial production, yet.

I'm pretty darned confident that it won't happen before I retire. But that's cheating.

Hi Daewoo! Heard cool things about you.

Koinesegg has one for their future Regera, but it runs completely on compressed air and hasn't been released yet. They ARE guaranteeing it for 50,000 miles under warranty however, but that's assuming its like Electric power steering and reaches crazy market saturation in a short span versus the rise of electrics.

1. Two stroke opposed designs need boost to work, with the earlier Achates needing both a supercharger AND Turbocharger along with attendant cutoffs. More problematic tho, is user perception- having two crankshafts gear-drive the output may be heavier than a head and cam assembly and will create gear whine, which that engine has and car manufacturers spend millions on exhaust alone. Plenty of dealerships have also refused to work on some EVs due to lack of knowledge a la' Fiat 500e.

3. Long strokes lower RPM and will in fact, outrun a flamefront at high revs. Their only use now is for air cooled engines like Harleys and lawnmowers where a ~5000-something redline isn't needed and you require that surface area of a long cylinder for cooling.

I think the primary reason would likely be emissions. Secondarily, OEMs have spent so many decades honing and perfecting 4-stroke Otto engines that it may be a stretch to lay a bunch of cash on the line for R&D of a new technology that may not pan out. Faced with several years and millions of dollars for something that might not work may seem scary to OEMs when the more vanilla alternative is "let's take last year's engine, try this chamber design, and lean out the trim a little."

10 years ago, it would be a far more viable risk. In today's market, if I were an auto manufacturer, all of my R&D money would be going into electric.

Long stroke engines had their place back when it was needed, but it makes fast piston speeds, high inertial loads on things, and offers no benefit to power or torque output. Back in the day it was incorrectly assumed that longer strokes made more torque, but a few billion dyno tests have proven that to be incorrect. Given the same displacement and flow/cam/compression/etc, a Buick 455 with it's short 3.9" stroke makes a darn near identical dyno chart to an Olds 455 with a 4.25" stroke. In reality, a long stroke simply limits the effective peak RPM, potentially shrouds valves with the smaller bore, and adds weight to the rotating assembly in most cases, so its benefits are (as others have said) in other areas like cooling, but for power/torque production, it offers nothing.

In reply to NickD :

I'd love to swap one of these into a project. I'm super, super interested in these engines.

In reply to Curtis73 (Forum Supporter) :

Well... I've heard that an undersquare engine will create more velocity in the intake tract, because the average distance the air has to travel once past the valve is longer. This results in more potential cylinder filling past BDC, and thus more torque.

I don't think valve shrouding makes a difference anymore given that so many engines now basically ignore the short side of the port altogether. 4 valve chambers offer a lot of neat benefits.

The other consideration is EVs. As cool.as the technology potential exists in these approaches. When will the research stop. When did steam.engines stop innovating?

Curtis73 (Forum Supporter) said:

Long stroke engines had their place back when it was needed, but it makes fast piston speeds, high inertial loads on things, and offers no benefit to power or torque output. Back in the day it was incorrectly assumed that longer strokes made more torque, but a few billion dyno tests have proven that to be incorrect. Given the same displacement and flow/cam/compression/etc, a Buick 455 with it's short 3.9" stroke makes a darn near identical dyno chart to an Olds 455 with a 4.25" stroke. In reality, a long stroke simply limits the effective peak RPM, potentially shrouds valves with the smaller bore, and adds weight to the rotating assembly in most cases, so its benefits are (as others have said) in other areas like cooling, but for power/torque production, it offers nothing.

Oh I agree about the torque thing. As for the RPM problems, according to Richard Holdener, modern engines are effectively no longer concerned with piston speed in most cases. I know this is an extreme example but some of the drag week mountain motor cars are turning 8k plus rpm with 5 inch strokes. Certainly you can have a 4 inch stroke and a 6,000 rpm redline in a warrantied engine without titanium rods or anything like that.

So what I'm wondering is why if you need 110 hp, you don't make a four banger with a 3 inch bore and a 4 inch stroke that redlines at 6,000 rpm. Why not have a 3.5 inch bore and 4.5 inch stroke in your truck engine that redlines at 5500 rpm? With the small bore you need less timing, can control detonation, and the hottest part of the expansion near TDC will be exposed to a very small surface area and thus lose less heat? Unless you care about specific output, and I don't know why you would, it seems like the valve area "problem" could be solved with more displacement.

GTwannaB said:

The other consideration is EVs. As cool.as the technology potential exists in these approaches. When will the research stop. When did steam.engines stop innovating?

This is certainly a possibility but, for all the advances in technology, EVs are still in an almost identical relative position to IECs as they were in 1905. In other words, they're quieter, more efficient and more torquey but cost a jillion dollars (and/or subsidies), require a bunch of nasty materials and have range/charging problems. If you don't believe me that the relative abilities of these strategies haven't changed much, you should check out the EVs in the Harrah Auto Museum.

There's a reason biofuels, ICEs and fuel cells are still being researched.

wheelsmithy (Joe-with-an-L) (Forum Supporter) said:

#3, Look at the Nissan QR25. They tried what is an astronomical stroke to bore for modern engines. They have some potential, but are pretty terrible engines (note, this is largely due to ingesting cats enema-style through the exhaust valves). Nobody else seems to be playing the long stroke game anymore. Give me an early FZR600 any day, or a 351 W.

I remember the QR25. It was torquey enough, but it was so lazy and vibration prone that it felt like it belonged in a compact truck. It had the same flavor as the old KA24s that Nissan built for the Hardbody and the 240sx.

With some more development it may have had some potential. Unfortunately, between the Honda K20's super efficient design and Nissan's own VQ35 beating it in every way possible, it didn't really stand a chance.