So, as per my ridiculous thread, im plotting boost for my challenge car.

I want to leave engine management out of this at this point in time. Just focus on hardware.

My understanding is that you need a turbo, exhaust from heads to turbo, exhaust from turbo to out of car, a boost refrenced fuel pressure regulator, oil lines into and out of turbo, blow off valve, piping from turbo to throttle body, intercooler, properly sized injectors, and an air filter for the intake side of turbo.

That all makes sense.

Except for how to spec the parts. Thats really bewildering.

How do you size a turbo, especially the $100 ebay units?

How do you size an intercooler?

Is injector supported horsepower the same as na with boost?

How big for exhaust before/after the turbo? How big for intercooler piping?

Robbie

PowerDork

11/20/17 11:54 a.m.

Dusterbd13 said:

So, as per my ridiculous thread, im plotting boost for my challenge car.

I want to leave engine management out of this at this point in time. Just focus on hardware.

My understanding is that you need a turbo, exhaust from heads to turbo, exhaust from turbo to out of car, a boost refrenced fuel pressure regulator, oil lines into and out of turbo, blow off valve, piping from turbo to throttle body, intercooler, properly sized injectors, and an air filter for the intake side of turbo.

That all makes sense.

Except for how to spec the parts. Thats really bewildering.

How do you size a turbo, especially the $100 ebay units?

How do you size an intercooler?

Is injector supported horsepower the same as na with boost?

How big for exhaust before/after the turbo? How big for intercooler piping?

You probably also need coolant lines to and from turbo. Actually specing the parts correctly could be multiple volumes of books. Specing the parts for challenge purposes is quite easy:

1. buy a turbo from a stock car with 50ish% more displacement than your challenge engine

2. buy a cheap intercooler, try to find the biggest cheap one

3. there are injector calculators on-line, but the simple answer is 'wrong question'. The engine makes slightly less power/injector on boost, but as boost rises, so does fuel pressure, so the injectors end up being bigger on boost. Just use the calculators.

4. exhaust should be as big as reasonable after turbo. 3inch seems to be common. for IC, match or be slightly bigger than the outlet of the turbo.

my opinion only, of course.

RossD

MegaDork

11/20/17 12:26 p.m.

This thread is relevant to my own concerns.

According to the calculation, i have big enough injectors already!

As far as the 50% bigger....

Its a 3.4 v6. Which would mean a factory 5.0 turbo. Which i dont think exists....

But there is a bunch of $100 t3/t4 turbos on ebay. I just have no idea what i am looking for.

Simple enough on the intercooler and piping.

Will try for 3 inch exhaust. Is it one of those things lime na, where if it gets smaller at the back, its no big deal?

Robbie

PowerDork

11/20/17 2:01 p.m.

Two turbos from 2.5l Volvos?

Diesel turbos may be good too. They have larger displacement than 5.0 but they will have lower rpm. Rpm x displacement is technically more accurate.

Robbie

PowerDork

11/20/17 2:07 p.m.

Why MORE displacement than his challenge engine?

If the turbo was sized for around a 3.5L engine, wouldn't it still work on this roughly 3.5L engine?

I can only think of Porsche and Nissan (GTR) that turbocharged an engine around 3.5L anyway....

Robbie

PowerDork

11/20/17 3:39 p.m.

wvumtnbkr said:

Why MORE displacement than his challenge engine?

If the turbo was sized for around a 3.5L engine, wouldn't it still work on this roughly 3.5L engine?

I can only think of Porsche and Nissan (GTR) that turbocharged an engine around 3.5L anyway....

Cuz generally factory turbos run out of air at high rpm in stock config. I assume you are going turbo for power... It wouldnt be bad to use a same size turbo, but it would be top end limited.

Displacement is a good rough estimate for turbo sizing, but it's more about airflow. The reason an HX35 works on a 2JZ is the 5.9L Cummins spins only 3000 RPM while a 3.0L 2JZ spins 6000+ RPM. Roughly the same amount of air, but remember the diesel runs super lean. Add in all the extra fuel on a gas engine and you're in business. GA Tech Wreck Racing made over 340whp in the MG Midget using that setup, and it was injector limited at 5500 RPM...

Or at least I hope that works out. I plan to triple-charge the Rice Rod. It has a 3.0L engine that makes 200 hp. I have 3 turbos from the 2.5L 1JZ engine, which used two of those turbos to make 280 hp. I figure I have 20% more engine and 50% more turbo than a 1JZ. Fill in the rest with fuel and I should be in 350 hp territory with minimal spool due to the smaller wheels. I also really don't know what I'm doing.

Robbie

PowerDork

11/20/17 4:06 p.m.

In reply to maschinenbau :

I can't wait to see that

codrus

UltraDork

11/20/17 4:50 p.m.

As far as injectors go, typically you want to run the engine somewhat richer in a boosted application, so you won't make as much power per cc/min as you would in an NA engine. The online calculators all take this into account, though.

As far as turbos, if you're looking at the cheap chinese knockoff turbos, well... sizing those accurately is pretty much impossible because they don't really provide any specs. If you're looking at used OEM turbos, then you want to look for something that, in factory condition, makes the power you want out of roughly the displacement that you have. Displacement matters, because turbos care about "pressure ratio". Imagine a 2L and 3L engine, both turbo, both making, say, 300 hp at sea level. The 2L engine might be doing it with a pressure ratio of around 2:1 (that is, 15ish psi of boost, or double atmospheric pressure), whereas the 3L engine is probably only running 1.5:1 (say 7-8 psi of boost). There's some flexibility here, but the efficiency of a turbo changes a lot with the pressure ratio, and the ideal turbo for those two applications would be different.

Personally I would stay away from diesel turbos, those aren't always capable of handling the higher EGTs of a gasoline motor.

As far as the regulator goes, if you're not putting a tunable ECU in the car (megasquirt, whatever), then you need a "rising rate" regulator. Normal manifold-referenced regulators will go up 1 psi of fuel pressure for every 1 psi of manifold pressure, and that's not enough on its own. Rising rate regulators will go up more than that. Rising rate regulators are generally considered "band aid" solutions, because they do a simple linear transformation on the fuel map, rather than letting you tune it accurately. OTOH, they are cheap. Note that they don't do anything about spark, so you'll need to do something about retarding the timing as well.

Find you a junkyard hy35 holset.

Robbie said:

Two turbos from 2.5l Volvos?

Diesel turbos may be good too. They have larger displacement than 5.0 but they will have lower rpm. Rpm x displacement is technically more accurate.

also lower VE (volumetric efficency)... and as I recall diesel has lower EGT...

I know the really fast turbobrick volvo guys use holset turbos.

Find a turbo from diesel from double your displacement application. Mashinebrau has the right idea it’s about The volume of gas.

So, i got a $40 turbo. Brand new. T04e and .50 ar are stamped on the side. I also got a precision turbo intercooler with it.

How do i identify if this is big enough?

I see some dust and dirt down on the impeller. Can i take it apart and clean it?

Any no money tweaks while its apart?

This is the first turbo ive ever held, let alone planned to install.

I also need to figure out a blow off valve, or wastegate setup. Or do i need both?

Robbie

PowerDork

12/4/17 8:14 a.m.

In reply to Dusterbd1not :

Pics or it didn't happen. Also probably more useful for really id ing what you have.

Bov is easy, grab one from any turbo Saab in a junkyard with a red di cartridge (the spark plug cover in the middle of the valve cover).

Does the turbo have an integral wastegate?

On the phone, so hopefully it works.....

Stefan

MegaDork

12/4/17 9:11 a.m.

So there’s no integrated wategate, so one will be needed to control the boost levels. The Porsche 924 Turbo uses a Porsche 911 Turbo external wastegate and are often ignored at local yards (even if they are pretty rare), these are great wastegates as they are rebuidable and tunable via cheap spring changes, etc.

BOV/Bypass Valve and the wastegate do different jobs.

A wastegate manages the pressure in the exhaust housing, which controls the boost output of the turbo (both peak pressure and the pressure curve).

A BOV quickly releases the pressure in the intake tubing to prevent compressor stall and reduce damage to the turbo and potentially help keep it spinning between shifts. It’s a quick release valve, it isn't for controlling boost levels.

Good luck.

I've built quite a few turbo systems and have become quite proficient. If you want to give me a call and chat through your build I am happy to do it.

A couple of quick observations:

- If you use a Holset turbo charger you only have to run oil lines. Holset turbos are oil cooled and do not have a water jacket. This will make you installation a little easier. Also, providing you don't over oil a Holset it is really tough to kill them. As mentioned earlier you can get a HY35 or H1c Holset for near nothing on ebay.

- Turbo chargers off of Diesel applications usually spool faster on gasoline applications due to teh respective exhaust densities and velocities.

- Most people overlook the importance of the turbo drain. Your turbo drain needs to be as big, straight, and direct as possible. Any obstruction to the drain will increase the chance of pushing oil past your turbo seals. This is probably one of the biggest causes of turbo failure.

- Internal wastegates can work just fine in most applications. They do sometimes have boost creep issues, but a wastegate hole port or enlargement can go a long way to mitigate those issues. External wategates tend to be expensive and sometime require coolant lines themselves.

Saabs are fairly common here, as well as volvo. Can i use a wastegate from one of those?

And, any issues with pulling apart to clean?

Lastly, the little silver valve that is operating by vacuum is a bypass valve, right? Gets installed into a hose in front of throttle body, and plumbed back in to.....

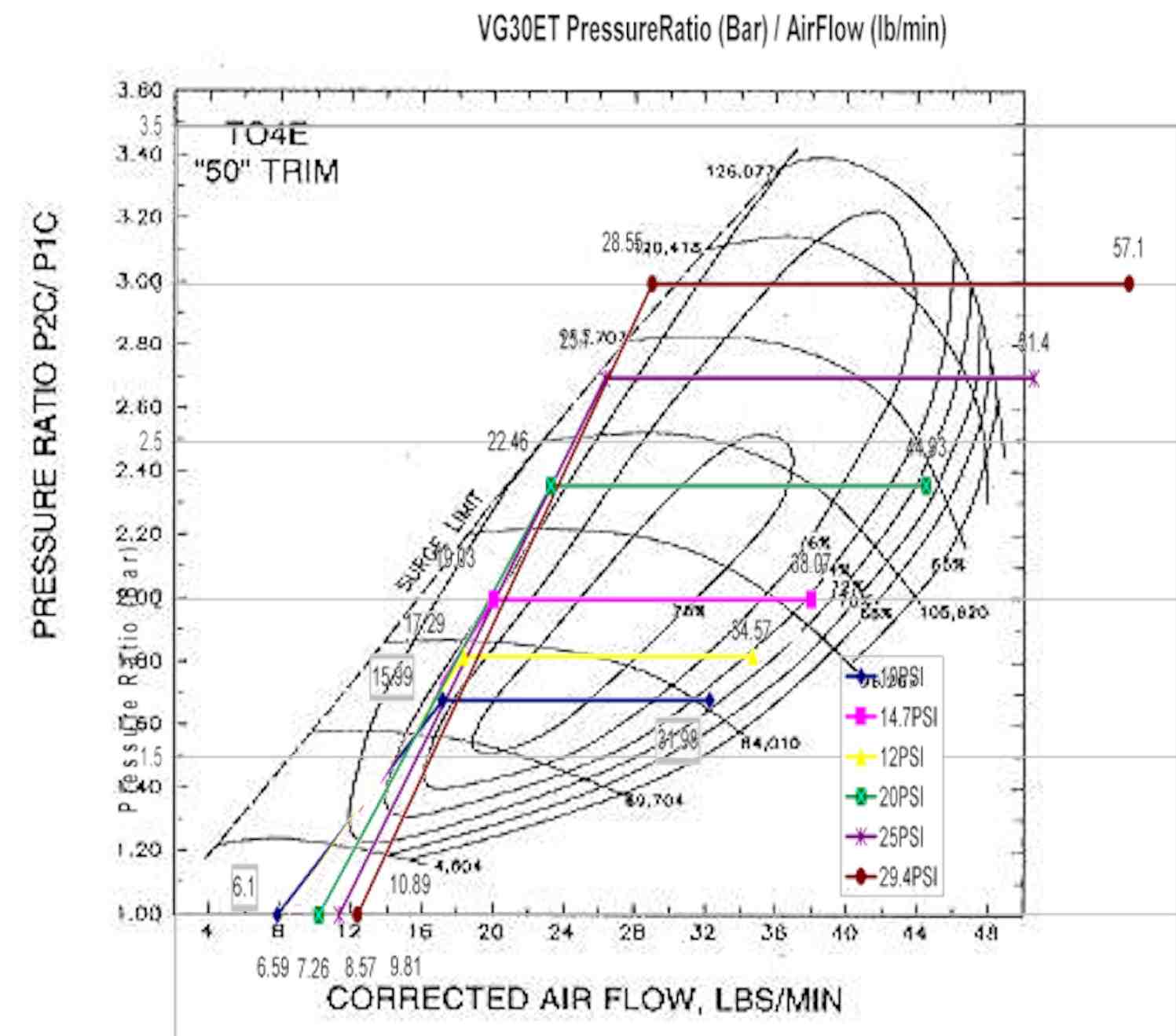

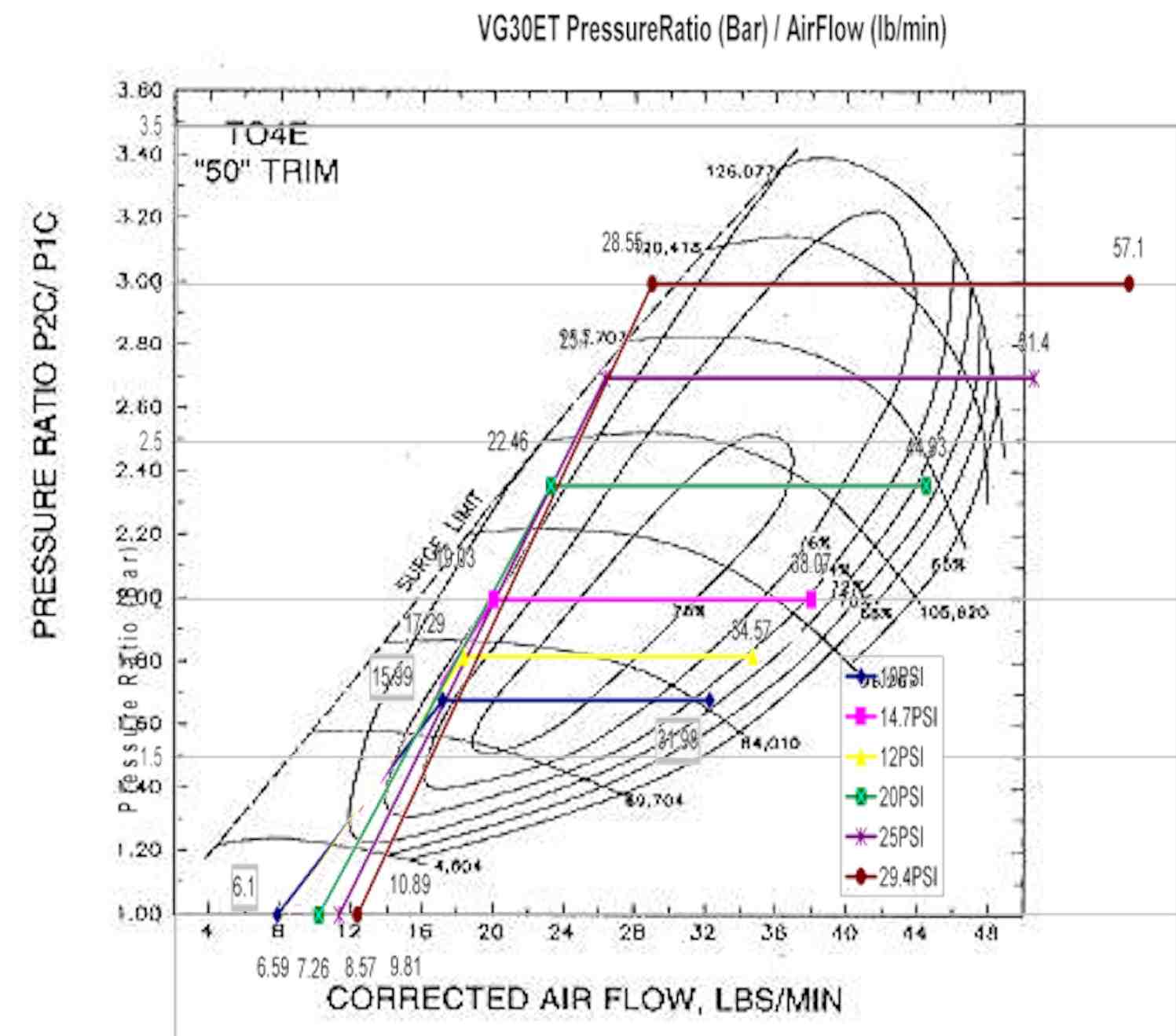

Looks like your 50 trim is rated at about 48lb/min. Rough rule of thumb is 10 hp/Lb/min. so, just a guess is 480HP at 2.8 ATM. Also, remember 2.8 ATM is about 26 PSI of boost. Hope this helps.

Robbie

PowerDork

12/4/17 9:44 a.m.

I think most all stock turbo cars will be 'integral wastegaste' which means the wastegate is part of the turbo exhaust housing. I don't know of any cars (except the Porsches I just learned about in this thread) that use external wastegate for junkyard pillaging.