I CAN lower the rack a little.

I bought these, but even with the bumpsteer correcting outer tie rods, it's not enough. They move the rack down too far.

I also saw these. I think they would work and solve all of my issues and I could lower the engine down about 1/4 inch and have hood clearance. I just don't want to drop another 200$ on something so simple (and I don't have it in the challenge budget).

Stampie, can you put up a pic of the stock rx8 subframe and steering rack? I can't quite get a clear picture of the rack mounting. Too much stuff in the way.

Thank you!

If it mounts on studs like my miata subframe, why not just loosen all the subframe to body hardware, stack 1/4 of alingment shims between the two at all hardware, and tighten back up? Easy button that motherberkeleyer.

And can you give me some marks on the alternator where its touching?

Dusterbd13-michael said:

If it mounts on studs like my miata subframe, why not just loosen all the subframe to body hardware, stack 1/4 of alingment shims between the two at all hardware, and tighten back up? Easy button that motherberkeleyer.

I have a gap there now. However much I lower the subframe will raise the front ride height. Also, I DO start getting into steering shaft to engine mount interference when I separate them too far.

Everything is just ALMOST fitting. Lolz.

I hope I'm not coming across as not listening to the advice!

I'm weighing all of the options and trying to figure out the best way to do this without compromising the steering geometry as cheaply as possible. However, there are other small limitations that make this more difficult that may come up. (Like the steering shaft issue).

Like all car builds, there are limitations and compromises. Tough to weigh them out.

The first iteration of this swap, I just hacked up the subframe and moved the mounts down. This made the car annoying to drive with all of the bumpsteer! The point of this exercise is to fix that!

wvumtnbkr said:

Dusterbd13-michael said:

If it mounts on studs like my miata subframe, why not just loosen all the subframe to body hardware, stack 1/4 of alingment shims between the two at all hardware, and tighten back up? Easy button that motherberkeleyer.

I have a gap there now. However much I lower the subframe will raise the front ride height. Also, I DO start getting into steering shaft to engine mount interference when I separate them too far.

Everything is just ALMOST fitting. Lolz.

Shouldn't. The shock and spring mount to the body, not the subframe. If anything, lowering the subframe will lower the vehicle slightly because of how the shock mounts to the control arm.

Lowering is still not ideal of course, because that wrecks roll centers. Unless that is what you meant: you'd have to space the springs up to make the front geometry right.

Personally I'd grind the steering motor as much as possible and use a smaller harmonic damper. Really, I'd be curious to see how it drove if one eliminated all that nonsense and depowered the rack. But then I feel about power steering the way some people feel about automatic transmissions.

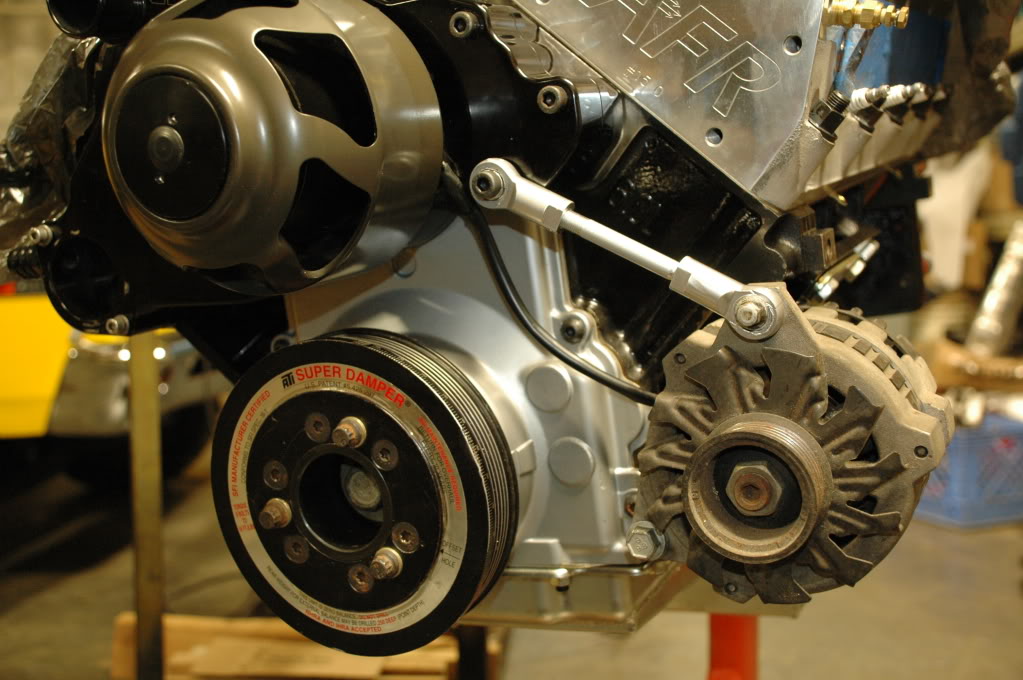

So I think you're overthinking this Rob. You're not looking for one place to find a half an inch. You're looking for eight places to find a 16th. Flap wheel the berkeley out of that point of the alternator. There's a good eighth of an inch you can take off there without compromising structural integrity. Then if you slot the mounting holes on the alternator bracket and maybe flap wheel the bottom side of the alternator some you can lower it another 16 to 1/8. That gets you a quarter inch of hood clearance more or less. That in addition to your subframe spacers should make the alternator clear the hood. Then the next hurdle is the bump steer issue. Am I reading this right? If we can lower the alternator we can raise the motor which allows you to raise the rack which reduces the bump steer issue. Is that a good summary?

wvumtnbkr said:

Dusterbd13-michael said:

And can you give me some marks on the alternator where its touching?

Does the alternator pivot? If so can you get a shorter belt? If not, can you modify or make a new bracket to lower it?

Does the intake plenum have enough clearance or is it 1/16" behind the alternator to touching the hood?

What engine is that?

In reply to Dusterbd13-michael :

The alternator bracket is weird, it wouldn't just be a matter of slotting. There is a face that it bolts onto on the exhaust side of the head.

edit: Unless you slotted all of the holes "sideways" instead of trying to move it "down".... kind of mudsliding the alternator away from the hood

I kinda wonder how difficult it would be to gently reshape the hood. Like, blocks of wood and couch cushions on the engine, push down on the sides and on the front and kind of half-ass English wheel the curves in the hood more bulbous.

Pete. (l33t FS) said:

In reply to Dusterbd13-michael :

The alternator bracket is weird, it wouldn't just be a matter of slotting. There is a face that it bolts onto on the exhaust side of the head.

edit: Unless you slotted all of the holes "sideways" instead of trying to move it "down".... kind of mudsliding the alternator away from the hood

I kinda wonder how difficult it would be to gently reshape the hood. Like, blocks of wood and couch cushions on the engine, push down on the sides and on the front and kind of half-ass English wheel the curves in the hood more bulbous.

I have thought about ways to gently get a Slight bulge in the hood. I wouldn't want to mess up the paint though (not that it's perfect).

Slippery said:

wvumtnbkr said:

Dusterbd13-michael said:

And can you give me some marks on the alternator where its touching?

Does the alternator pivot? If so can you get a shorter belt? If not, can you modify or make a new bracket to lower it?

Does the intake plenum have enough clearance or is it 1/16" behind the alternator to touching the hood?

What engine is that?

Alternator does NOT pivot. It has mounting points on 3 different "planes".

This is a gm 3900 60 degree v6.

Dusterbd13-michael said:

So I think you're overthinking this Rob. You're not looking for one place to find a half an inch. You're looking for eight places to find a 16th. Flap wheel the berkeley out of that point of the alternator. There's a good eighth of an inch you can take off there without compromising structural integrity. Then if you slot the mounting holes on the alternator bracket and maybe flap wheel the bottom side of the alternator some you can lower it another 16 to 1/8. That gets you a quarter inch of hood clearance more or less. That in addition to your subframe spacers should make the alternator clear the hood. Then the next hurdle is the bump steer issue. Am I reading this right? If we can lower the alternator we can raise the motor which allows you to raise the rack which reduces the bump steer issue. Is that a good summary?

Yes, good summary. My concerns are:

1) that now I would have a modified alternator (not a huge deal)

2) I have a different crank pulley than stock and I need to refabricobble the rx8 tone wheel onto THAT pulley.

3) I will still need to recreate my driver side motor mount to stop the steering shaft interference. Pic below at current state (this is WITH the subframe gap and alternator touching hood)

So, maybe I AM over thinking this.

Why not just get some of the steering rack relocation brackets as shown above? They move the rack 1 inch down. I have 1 inch bumpsteer correcting outer tie rods. I can then move the engine down 1/2 inch and still have at least 1/4 inch clearance between the rack and crank pulley.

Am I crazy trying to reinvent the wheel here? What other negative impacts are there to moving the rack down and using the outer tie rods to correct for the rack vertical displacement?

Since I have no direct experience with lowering the rack and the tie rod ends I'd have to ask what the feedback from the RX8 guys is on that. Seems like if it's an engineered solution that other guys have tried it and there should be enough reports out there to know whether it's a viable option or not. It sounds like the easy button that solves all your problems though.

Dusterbd13-michael said:

Since I have no direct experience with lowering the rack and the tie rod ends I'd have to ask what the feedback from the RX8 guys is on that. Seems like if it's an engineered solution that other guys have tried it and there should be enough reports out there to know whether it's a viable option or not. It sounds like the easy button that solves all your problems though.

It is the normal path. However, the set of adapters I have on hand moves the rack 2 inches down. After installing them, I still have crazy bumpsteer, even with the outer tie rods moved down to the lowest setting (1 inch down).

That's what sent me down this path. (Meaning finding a different solution).

Then, through researching the last few days, I found those Collins adapters which only move the rack 1 inch.

I am a bit hesitant to spend another 200$ for it to not work out either. Also, wouldn't fit within challenge budget.

I think I'm going to take the rack off, put everything (engine, subframe, etc) where they are happy and then see how much I actually need to move the rack.

Question... I have researched and searched, and I am still unclear if there are any negative side effects of moving the rack down other than bumpsteer. Do the outer tie rods (bumpsteer correction kits) fully cure bumpsteer? Is there a tradeoff?

Thanks for all the input!

I think Duster is correct attack the alternator clearance first, get everything you can there. Then I woul look for a non or de powered rack with a good fit geometricly speaking and add a Prius EPS to it.

So, going to another, smaller rack means that I need to fabricate the eps system into the car, I would need to get another rack, and I would need to modify the drivers side engine mount. Plus, modifying the alternator.

That's alot. If anybody can tell me what happens when I move the rack AND the tie rods down (the same amount), that is the WAY easier button that might not have any downsides.

Thanks for all of the ideas so far!

In reply to wvumtnbkr :

You have to modify the engine mounts anyway. How much does the hood curve, and how much clearance will you gain by shifting the engine to the left and/or rotating the assembly to move the right side down?

Mazda did NOT mount the engines straight in RX-7s, they were heavily angled to the left so the exhaust manifold would clear the steering box in RHD markets. So in this respect you would not be forging new ground.

For the rack, one option might be to use offset rack spacers to return the tie rods to their original angles while the rack is offset, apart from any changes in overall width that may result this could return the steering geometry to stock:

NOHOME

MegaDork

7/27/23 12:17 p.m.

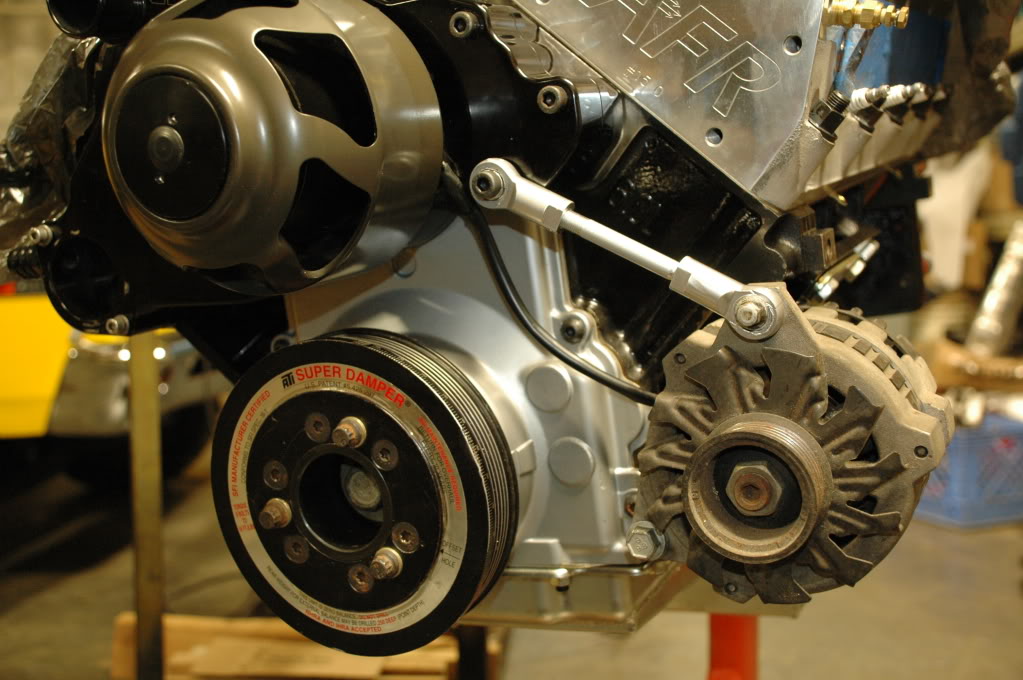

What am I looking at here? Is there space under the sticker or critical sturr just below? The thought is that if there is a void below, you can carve a scallop with a welded in filler to make room

Not enough pics to be sure, but it looks like the alternator can come down with a custom bracket. The alloy factory stuff is always a bit space lenient.

Need a lot more pics to make valid opinions.

Is the alternator actually hitting the hood or just the inner hood structure? Can you cut the inner hood structure for a little more clearance?

Another thought would be using a LS truck alternator that has two bolt holes and do a simple heim joint on one end.

NOHOME said:

What am I looking at here? Is there space under the sticker or critical sturr just below? The thought is that if there is a void below, you can carve a scallop with a welded in filler to make room

Not enough pics to be sure, but it looks like the alternator can come down with a custom bracket. The alloy factory stuff is always a bit space lenient.

Need a lot more pics to make valid opinions.

That is the "linear motor" of the steering rack. It can not be modificated.