RacetruckRon said:

Is the alternator actually hitting the hood or just the inner hood structure? Can you cut the inner hood structure for a little more clearance?

Another thought would be using a LS truck alternator that has two bolt holes and do a simple heim joint on one end.

The inner hood structure is cut. Hitting the actual inside of the hood panel.

Pete. (l33t FS) said:

In reply to wvumtnbkr :

You have to modify the engine mounts anyway. How much does the hood curve, and how much clearance will you gain by shifting the engine to the left and/or rotating the assembly to move the right side down?

Mazda did NOT mount the engines straight in RX-7s, they were heavily angled to the left so the exhaust manifold would clear the steering box in RHD markets. So in this respect you would not be forging new ground.

Engine is shifted to the passenger side to make clearance for exhaust / starter/ steering rack.

Rotating is not possible without modifying the ppf.

As far as modifying the mounts, I just need to put spacers under them. No cutting and welding (if I just move the engine down).

Okay. Tightened up the gap on the subframe.

Lowered the engine so it clears the hood. Shimmed the engine mounts.

Zip tied the rack 1 inch down from stock.

Steering shaft clears.

This is the easiest thing to try at least. Just requires making / buying those rack relocation spacers.

Space between rack and crank pulley.

nocones

PowerDork

7/27/23 1:39 p.m.

Assuming it is straightforward to execute I would lower the subframe up to 1/2" and raise the motor assuming this enables stock rack positioning.

I would not space the springs leaving the ride height at current.

Yes your geometry will be different. It will be the same as a RX8 with a 1/4-1/2" drop. I don't believe it will matter or you will notice.

If it brought about wierd behavior because the front and rear roll centers where slightly different, I would lower the rear to match and run slightly taller tires in the back.

GameboyRMH said:

For the rack, one option might be to use offset rack spacers to return the tie rods to their original angles while the rack is offset, apart from any changes in overall width that may result this could return the steering geometry to stock:

That is AWESOME! I could definitely do that if the geometry is messed up after lowering the rack. That would solve this issue and I can leave the engine and subframe where they currently are.

Now you can pull the struts and check toe change with wheel travel using toe boards,lasers on the rotors or whatever your favorite way to do it is.

wvumtnbkr said:

Stampie, can you put up a pic of the stock rx8 subframe and steering rack? I can't quite get a clear picture of the rack mounting. Too much stuff in the way.

Thank you!

Sorry been a busy day. This what you're looking for?

wvumtnbkr said:

That is the "linear motor" of the steering rack. It can not be modificated.

Oh it can be. There's a YouTube video where a guy takes all the magnets out. Then I assume you could use a smaller tube. But I know you don't want to depower it.

It looks like moving the rack down will not only change your bumpsteer but it will also move the rack forward, which will negatively affect Ackerman. It looks like those drop brackets will be even worse for trying to make an RX-8 handle like a '79 Mustang.

Since the NC has a shorter wheelbase, I wonder if the NC subframe holds the rack further back, so the spacer dealy will actually move the rack to a "correct" location for Ackerman. Or if Mazda made the steering arms different NC vs RX-8. Or if they even bothered and one chassis has too much or the other has not enough.

Some work with a press to adjust the steering arms can fix Ackerman as long as the tie rods aren't into the rotors yet.

Pete. (l33t FS) said:

It looks like moving the rack down will not only change your bumpsteer but it will also move the rack forward, which will negatively affect Ackerman. It looks like those drop brackets will be even worse for trying to make an RX-8 handle like a '79 Mustang.

Since the NC has a shorter wheelbase, I wonder if the NC subframe holds the rack further back, so the spacer dealy will actually move the rack to a "correct" location for Ackerman. Or if Mazda made the steering arms different NC vs RX-8. Or if they even bothered and one chassis has too much or the other has not enough.

Some work with a press to adjust the steering arms can fix Ackerman as long as the tie rods aren't into the rotors yet.

I did get some spacers made from a friend who does this thing all day long.

Can you tell me about the steering arms and how they should be modified for Ackerman?

Thank you!

Um, just now seeing this thread,sorry about that!

Will review and get some potentially useless input posted shortly.

Ok, so I think to do this the "right" way, we'd first want to make sure we understand the problem correctly. Ie, have you checked the bumpsteer with rack in stock location and where it currently "fits"? Like take the spring out, lock the steering wheel, attach something to the wheel that measures toe. Move the wheel up and down through the suspension travel and see how much the toe angle changes. Would probably want to do this at various "turn" angles.

I realize the above is a lot of work and the best answer is probably to get the rack in the stock location, but still might be helpful in figuring out the true problem.

However, if it were me, I'd probably do like nocones suggests. Drop the subframe all together so the hubs and the rack stay the same relative to each other, and then fix ride height with shorter springs. This does suck if you want to lower the front even more though, as you will create problems other lowering too much.

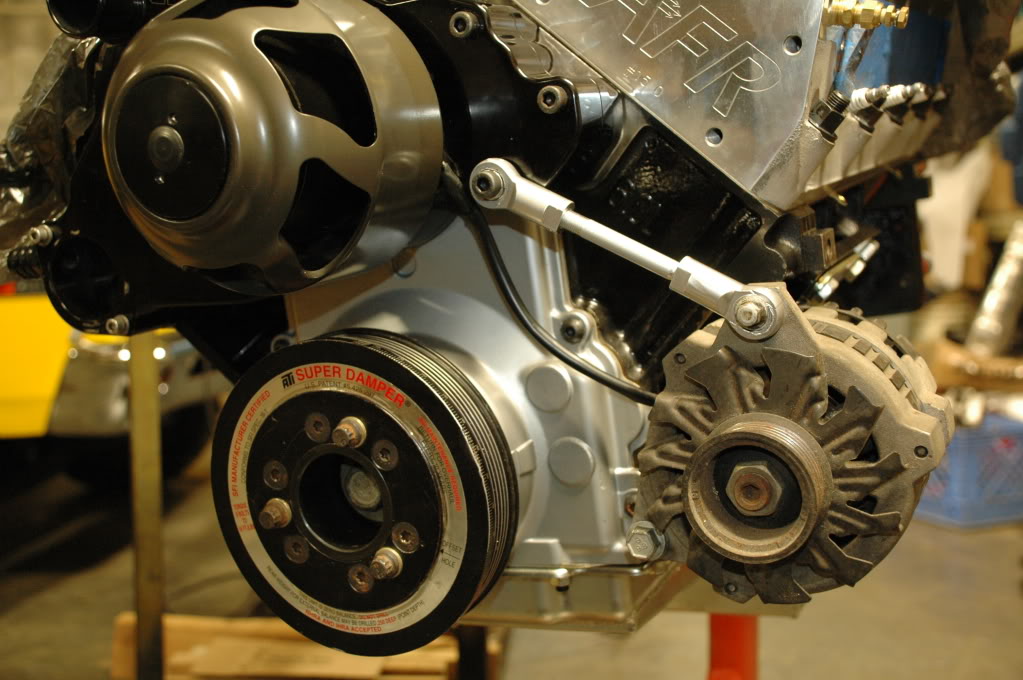

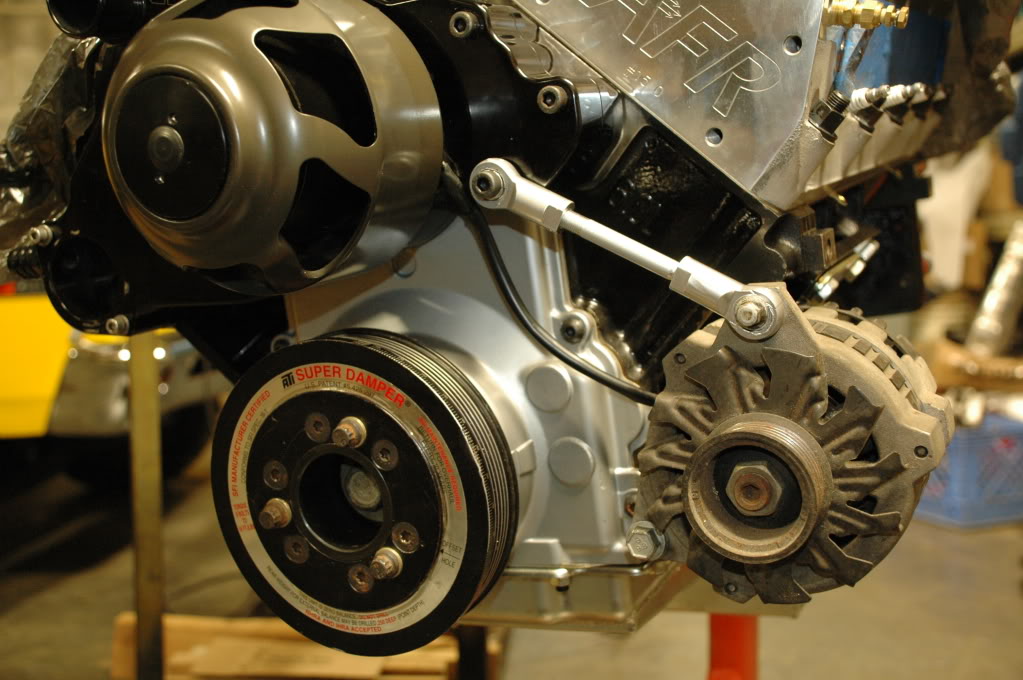

Has it been asked - does someone make a smaller 'underdrive' pulley for this motor? Might be worth installing if there is one just to see.

In reply to wvumtnbkr :

Hi, @wvumtnbkr

I know it has been a few months of inactivity on this page but I came across it while looking up something else.

I have the same GM 3.9L in my Porsche 944 so I dealt with similar tight hoodline constraints.

You appear to have more room than I do, but what you could do is use the coolant crossover/alternator mount from a 2009+ Buick Lucerne 3.9L. These put the alternator on the Driver side but mount it about 1.5-2" lower down relative to the Impala/Uplander style alternator mount you have currently. The alternator is Lucerne-specific but some guys (Fieros) have made cheaper GM truck alternators fit the bracket with some grinding.

The Lucerne bracket puts the belt tensioner where your alternator currently is. The timing cover/water pump/AC/etc is otherwise the same.

In reply to v2rocket :

Please tell me there is a built thread for your 944. If there isn't can you make one here please? That sounds like something fun that I want to know about.

In reply to Dusterbd13-michael :

I never did a build thread in the process, but the closest thing I wrote up is linked here.

I got the 3.9 engine in August 2020 and started cleaning/resealing it and planning. I took the 944 engine out 11/27/20 and had the 3.9 installed and running on 11/26/21. Had to do a lot of revisions to the steering etc so the first drive wasn't until 5/31/22. I drive it every weekend, it's very quick, sounds good, a lot of fun.

https://944hybrids.forumotion.com/t3804-lz9-3-9l-v6-in-1985-944-gm-60-degree-v6-swapped

Awesome!

That setup you mention may actually help me with the turbo planning I am doing at the moment.

Btw,I did end up moving the rack down about 5/8 of an inch. Car drove beautifully! (Until I spun a bearing). Engine is being rebuilt at the moment in my garage.