Different kind of LS swap;

Generally, with these types of conversions, the amount of modifications required brings the cost up very close to a typical Lycoming etc.

With an LS, you also get to carry around (and have the point of failure) of a radiator / water pump etc. Although, this has a benefit of not having to worry about shock cooling when descending.

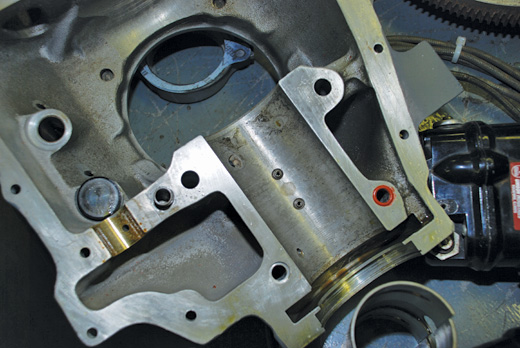

For aircraft conversions you also want to pay a LOT of attention to the prop bearing. The bearing on a Lycoming is HUGE. The pic seems to show a rather stout nose case.

One of my all time favorite planes from Oshkosh days was the Lancair-IV-P V8. trying to find it but IIRC it had the fuel consumption of a C172 at like 1.5 the cruise speed. Of course this was older GM V8 technology.

The biggest single issue in most auto conversions is the gearbox. Unlike a typical aircraft engine, car engines don't produce much power at the rpm the propeller needs to swing at. The benefits come in the form of fuel efficiency, power, and common, much less expensive parts.

aircooled said:With an LS, you also get to carry around (and have the point of failure) of a radiator / water pump etc. Although, this has a benefit of not having to worry about shock cooling when descending.

The pic seems to show a rather stout nose case.

It's probably an integrated gear reduction box and thrust bearing

so... water cooled, pushrod, engine with high power, and gear reduction....

sounds a lot like a Packard or Merlin ![]()

sleepyhead the buffalo said:aircooled said:With an LS, you also get to carry around (and have the point of failure) of a radiator / water pump etc. Although, this has a benefit of not having to worry about shock cooling when descending.

The pic seems to show a rather stout nose case.

It's probably an integrated gear reduction box and thrust bearing

so... water cooled, pushrod, engine with high power, and gear reduction....

sounds a lot like a Packard or Merlin

an eensey teensey Merlin, maybe. I think they were 27 liters?

Supposedly the big problem with these kinds of conversions is that while you can add a bunch of power with an engine that costs less than the original, by the time you've added the necessary extra equipment (radiator, coolant, fans, gear reduction, etc) you've added like 200-300 extra pounds of stuff. That's a substantial fraction of the available payload weight on the plane, and those limits mean a lot more on an aircraft than they do on a car. So that significantly reduces the utility of the airplane afterwards.

sleepyhead the buffalo said:aircooled said:With an LS, you also get to carry around (and have the point of failure) of a radiator / water pump etc. Although, this has a benefit of not having to worry about shock cooling when descending.

The pic seems to show a rather stout nose case.

It's probably an integrated gear reduction box and thrust bearing

so... water cooled, pushrod, engine with high power, and gear reduction....

sounds a lot like a Packard or Merlin

Check out EPI

http://www.epi-eng.com/gearbox_products/mark-9_pictures.htm

gearheadmb said:How much HP do planes that size usually have from the factory?

180-210 hp in a flat 6 air cooled engine designe from the 40's

Would there be any advantage to a shiftable gearbox on a prop driven aircraft? Then use a lower gear during takeoff and climb but shift into a higher gear(s) once at cruising speed (perhaps enabling a higher top speed).

KyAllroad (Jeremy) (Forum Supporter) said:Would there be any advantage to a shiftable gearbox on a prop driven aircraft? Then use a lower gear during takeoff and climb but shift into a higher gear(s) once at cruising speed (perhaps enabling a higher top speed).

Nope.

Propellers are variable pitch in order to keep the engine operating at it's most efficient range.

2800 is about the upper limit for propeller RPM on small aircraft. Anything more than that and the blade tips are going supersonic which causes a whole bunch of problems.

I was a P-license AME until the industry sucked all my life force and I quit.

No engine likes being upside down if not equiped, including aero engines. If you keep positive Gs, an engine and airframe won't know its upside down. That's how Tex Johnston barrel rolled the Dash 80 prototype. I've never seen an auto engine conversion in an aerobatic situation.

My LS comversion sweet spot is the Republic RC-3 SeeBee.

EDT (Forum Supporter) said:The biggest single issue in most auto conversions is the gearbox. Unlike a typical aircraft engine, car engines don't produce much power at the rpm the propeller needs to swing at. The benefits come in the form of fuel efficiency, power, and common, much less expensive parts.

You'd need a gear box anyway, to get the prop high enough.

Unless you used an inline PSRU and mounted the engine upside down, if you wanted to prove a point I guess.

In reply to ShawnG :

Rotary aircraft swappers mount the engines sideways, "plugs up", with the manifolds side down. Manifold side up makes the oil drain back situation easier but plugs up gets the prop up in the right axis.

However if you thought a V8 needed gear reduction, try a rotary! The huge advantage rotaries have as an aircraft engine is fault tolerance. Even if you hurt compression, as long as it doesn't stall it will stay running, albeit at reduced power. If you lose all the coolant, the engine will not seize from overheating, so you will be able to safely land. It will not ever start again once it cools off, but that's a future problem not an immediate one.

In reply to Pete. (l33t FS) :

That crackpot Moller has been experimenting with rotary engines in his "skycar" for years but I don't think it's gotten anywhere. He keeps managing to find new investors though.

In reply to ShawnG :

Moller's main contribution is the invention of the Supertrapp muffler.

Which, ironically, sucks on rotary engines, because by the time you make it unrestrictive enough, it is no longer quiet enough compared to more convenional mufflers.

gearheadmb said:How much HP do planes that size usually have from the factory?

The plane pictured (looks to be a 172) will normally have 150 hp, but a LOT of torque (350 CI engine).

The LS conversion also looks to have a full electronic ignition, another point of failure. Lycomings have dual magnetos (and dual plug) ignitions, VERY hard to have them both fail. Heck, you can throw the battery and generator out of a traditional plane and it will fly fine (there might be a weight and balance issue though). I suspect you can not say the same for the LS conversion.

You'll need to log in to post.