KevinGale said:

For as long as I have raced this car I have had this problem. (Notice the bend in the clevis)

I'm not entirely sure when it bends. My main theory is it happens on bumpy Mt Ascutney which is usually the culprit in any bent or broken suspension components. I've tried buying a couple types of clevis joints but they all bend. I mention this to Paul Tinguad. Paul has opened a shop Supercar Machine Shop and decided to help me out. This is what he made.

You can see the new clevis is much more robust than the original below. We will see how these hold up.

Here they are on the car

I can't remember if I've let you know before but I really enjoy this thread. I lived in Upstate NY for the first 4 1/2 decades of my life and I spent a little time around Troyer modifieds in the early '80s. While I never attended any hillcimb events and my Troyer experience involved left hand corners on dirt with the steering wheel turned mostly to the right there's enough familiar stuff in this thread that it leaves me with a happy sense of nostalgia every time I visit it.

Related to the bent clevis issue. That really looks to me like the suspension is over constrained and is binding at the travel extremes and I'm wondering if a HEIM joint might be more appropriate than a clevis.

APEowner said:

I can't remember if I've let you know before but I really enjoy this thread. I lived in Upstate NY for the first 4 1/2 decades of my life and I spent a little time around Troyer modifieds in the early '80s. While I never attended any hillcimb events and my Troyer experience involved left hand corners on dirt with the steering wheel turned mostly to the right there's enough familiar stuff in this thread that it leaves me with a happy sense of nostalgia every time I visit it.

Thanks

Related to the bent clevis issue. That really looks to me like the suspension is over constrained and is binding at the travel extremes and I'm wondering if a HEIM joint might be more appropriate than a clevis.

I do use all the travel. There are no binds in the suspension and under compression the frame hits before it bottoms out from travel. The ball joints limit droop travel. So I don't think the clevis is under a load in either case but I could be wrong. (That's always an option  ) If these bend I may just try using a heim joint just bolted through the control arm. I'll have to drill the hole out to take a bigger bolt than the 3/8" that the clevis uses since I don't think that would be strong enough under single shear but I don't see any reason why I can't make that hole big enough to take at least a 1/2" bolt and maybe 5/8"

) If these bend I may just try using a heim joint just bolted through the control arm. I'll have to drill the hole out to take a bigger bolt than the 3/8" that the clevis uses since I don't think that would be strong enough under single shear but I don't see any reason why I can't make that hole big enough to take at least a 1/2" bolt and maybe 5/8"

Got the notification yesterday that the spring Ascutney event has been canceled. I expected it but of course I was hoping it wouldn't happen. The next event scheduled is Okemo in mid June. We will see what happens with that.

I did get to spend some time in the garage this last weekend. Got a few things done including a new steering shaft. The old shaft was still working but the u-joints had a little play in them. This time I decided to do them what I consider to be the right way and used Woodward splined steering shaft stubs.

Notice the stub on the table and the other that is slipped into the end of the shaft tubing. These are Woodward ST201B stubs for 3/4" x 0.065 wall tubing.

Using these stubs has a few advantages over the weld in universals I see everywhere else.

- You can't damage the u-joint via the heat of welding. Normally you have to be really careful welding in the u-joint so you don't get it too hot and cook out the grease and maybe melt any rubber seals. With these stubs that isn't a problem

- You can disassemble the steering shaft to get it in and out of the car.

- You can replace a bad u-joint without have to fabricate a new shaft.

Here is the mock up of the new shaft in the car before the final welding. I even went all out and bought the aluminum steering heim.

Oh and before someone points out the phasing of the u-joints is incorrect in the picture above I will say that is yet another advantage of the weld in splines. The phasing is not fixed by the welding and it can be changed at any time. For the test fit I wasn't even thinking about it. The old shaft I am replacing also had the phasing wrong but in that case it was just an error. Somehow the phasing changed and I didn't noticed until after I was done welding. And with weld in u-joints that is that! I would have had to cut it apart and start over again. Even then I would have had u-joints that were heated by welding twice unless I also wanted to replace those. Yup I like the weld in splines a lot!

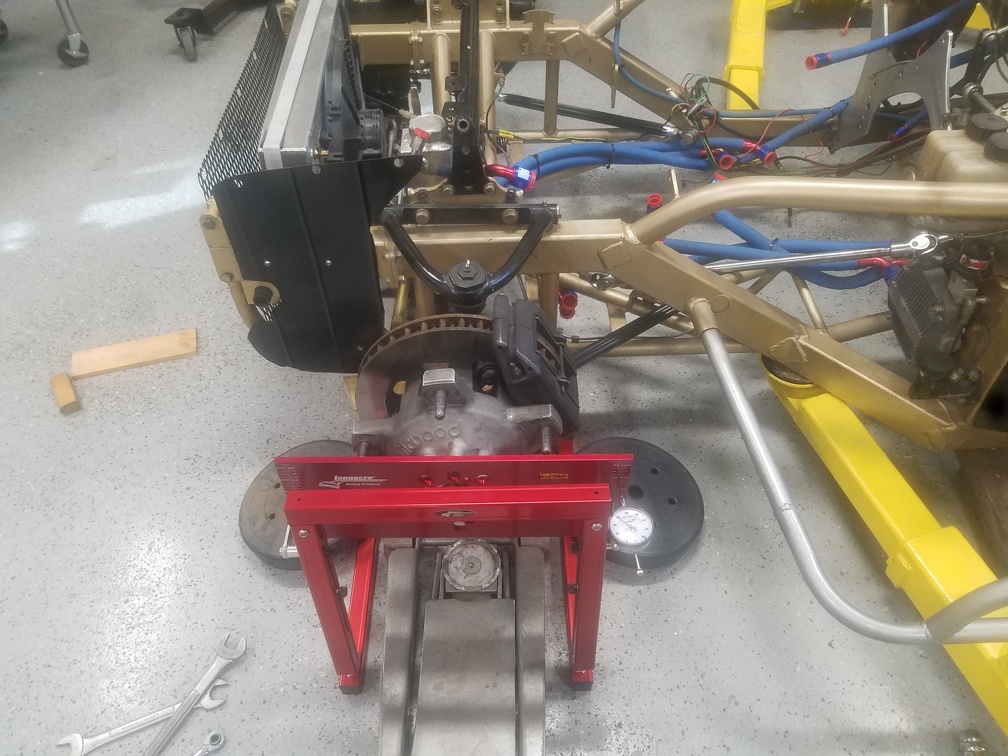

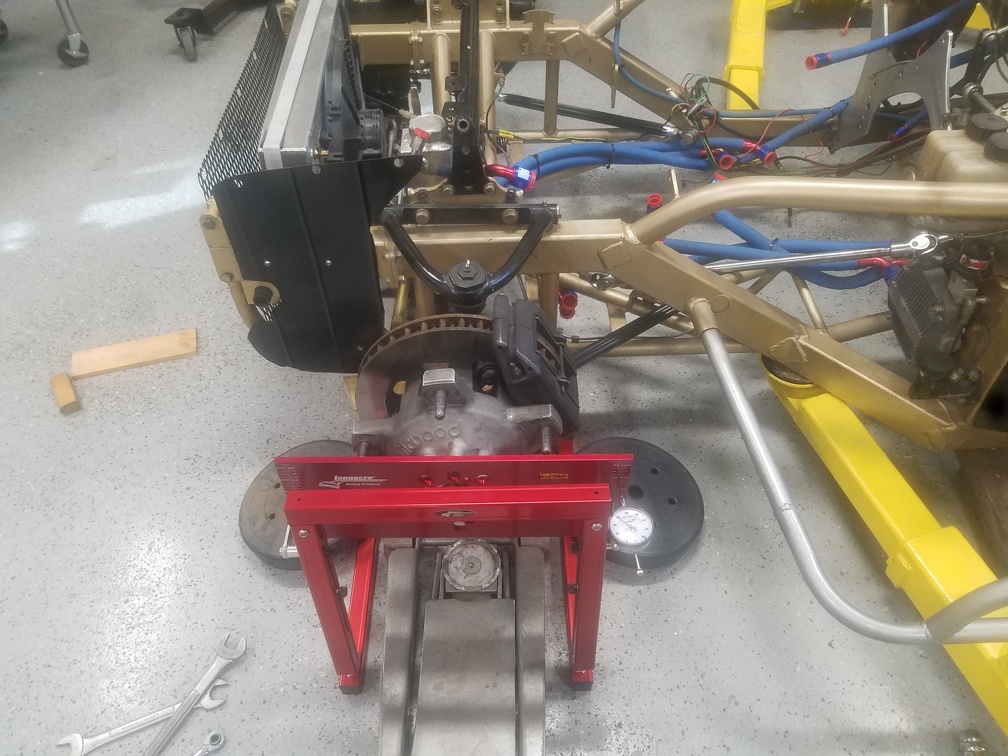

Doing a rough check of bump steer. I wanted to change the heims I was using to sweet tie rod ends. Unfortunately it looks like that does bad things to the bump steer. The Howe tie red ends are adjustable but all the adjustment is in a direction I don't need. Looks like I will just have to replace the heims.

As a reminder to myself the steering rack is centered with 3.25" of the servo piston is sticking out on the left (driver's) side of the car and 3.5" is sticking out on the right.

Regarding that bent clevis....a couple things my father in law aircraft mechanic taught me some years back that I offer for whatever they are worth:

If you got stuff bending in a moving assembly you probably need to think more about potential movement in all three dimensions or planes. I know that has helped me figure out or avoid a few problems.

And if you make one bent thing stronger in an assembly, you are moving the effect of that bending force somewhere else. Thats not a reason to not make it stronger - just keep any eye on connected stuff to ensure they are strong enough to not bend or crack.

Love your car. There is something about cars that are constructed ground up for one particular purpose. Enjoy.

Nothing really to add, just keeping up.

Wait. One thing struck me. I have heard once you go to heim joints you never want to go back.

Why did you want the rod ends?

Bent-Valve (FS) said:

Wait. One thing struck me. I have heard once you go to heim joints you never want to go back.

Why did you want the rod ends?

The Howe units are adjustable and rebuildable. And they also have a built in bump steer adjustment. I just thought they would be nicer long term. But in this case they just won't work.

That is a bummer.

I need to learn more about suspension parts.

I do understand wanting something that's rebuildable. The coilover units in my ZX2 are supposed to be rebuildable. I found the company that made them but they are so old they don't show up on the website.

The bent clevis may be a result of the sway bar imparting a twisting force on your lower control arm.

Looking at the way it is mounted significantly off center of the LCA.

bentwrench said:

The bent clevis may be a result of the sway bar imparting a twisting force on your lower control arm.

Looking at the way it is mounted significantly off center of the LCA.

Maybe, my theory is a combination of braking and bumps at Mt Ascutney. The clevis gets put under considerable rotational strain under braking. I think normal braking isn't enough to cause a problem but at Ascutney I am braking while going over huge bumps. So the front wheels leave the pavement which under braking which pretty much instantly stops the wheel. Then while the wheel is stopped the tire gets driven hard into the next bump. At that point the tire has far more grip than normal because the rubber is being driven into the bump. (The bumpy pavement at the top of Ascutney is also well know for having great grip.) So the brakes are on hard, the wheel is stopped and in the air. then at 60+ mph I'm hitting something the size of the biggest speed bump you have ever seen.

One of the reasons I love the top of Ascutney is I have a car car that can take the abuse. I'm merciless on the top. I don't slow down for the bumps at all. Most people are trying to save their cars and slow down.

Bent-Valve (FS) said:

That is a bummer.

I need to learn more about suspension parts.

I do understand wanting something that's rebuildable. The coilover units in my ZX2 are supposed to be rebuildable. I found the company that made them but they are so old they don't show up on the website.

Had that problem too. Find something nice and next thing you know the company either is out of business of they don't make or support the product anymore.

First the bad news since it directly impacts racing. I lost my job last week. Mostly a Covid-19 thing. The company is just laying off a lot of people and for some reason I was the one picked on my team. I'd worked for the same software product for almost 32 years so I'm a bit out of practice with this job search thing. I will now have more time to work on the car but I certainly won't be spending any significant money on it until I have a job again. I'm also seriously considering pulling out of Mt Washington since I would get back the almost $900 entry free and I may need that money for other things. Not even sure I will want to spend the money for entry fees for NEHA events (and tires and fuel, etc). I will go to the NEHA events and work for sure. I've done the go into debt racing on credit thing in the distant past and I won't do it again. It's a bad long term plan. Racing is for when I have extra money not for when I'm worrying about how to pay the bills. (It's not really bad short term since the company did give me a severance package that will pay out over about 7 months). My wife's architectural business is basically dead right now as well so we certainly are down on income overall.

Back to our regularly scheduled programming: Since the last update I did get the bump steer mostly figured out. I'll need to do a final check once the car is all back together. I'm also getting the motor ready to go back in the car. Motor Plate is on along with the water pump, alternator and dry sump.

Will keep you and the missus in my prayers.....was outa werk myself from sept2015 till mar2018......hang tough this too shall pass.....peace out.

In reply to KevinGale :

I was laid off in October of 2008 the last one left. ( one of 22 million unemployed at the time) I got frantic , on line, in person, back door, networked, wore out shoe leather, suits, etc spent a lot of money trying to get a job. Chased bad jobs, got conned twice taking no paying jobs.

I-applied for jobs I was massively over qualified for, anything to get income.

Went through Unemployment insurance, my savings, my retirement, etc etc sold things I never wanted to race cars, collector cars, etc.

5 years later I got my first paying job as a part time gig driving a school bus Yes it was humbling. To go from over 6 figures and a company Jet to $15 an hour for a little over 22 hours a week.

My advice? Yes get your entry fee back, do the work you can on that money. Don't spend more until you are earning a similar income. Apply for every work from home position you can dream up.

Realistically this isn't over until they get a vaccine and that's 18-24 months away. Then the whole economy has to crank up again. You'll be how old when that happens?

I was at my prime, fantastic resume, well documented, great letters of recommendation. Awards, prizes, but I was into my 60's by then and there were a lot of younger people, with more current qualifications. I didn't know the current Jargon, software, etc. besides I was down to one presentable suit and had to count change to buy gas for the interviews.

The whole Mt Washington entry fee decision turned out to be moot since the event was postponed a year. So everyone got their money back and I am on the list for next year. Since my last post the Mt Okemo event has also been canceled. Right now the first event of the season will be Burke in late July.

I haven't been spending a lot of time on the car but I have got in a some time fixing my Mt Ascutney off road incident. Here is where I am plating the frame rail that got smashed. (Still have some welding to do) There was a whole lot of heating with a torch and beating on it with a hammer to get it back in shape enough to get a piece of steel to fit over it. I cut a piece of 2"x 3" tubing lengthwise to effectively make a big piece of angle iron to plate the dent.

I also think I forgot to mention I found time to drop the engine back into the car. It is just bolted in place nothing really connected yet. I did that so I could test if the new headers fit.

Sometime just before I started this build thread John Reed and I built custom headers for the car. It was a major project but in theory there were some power benefits. In practice I never noticed the slightest difference from the old junk headers. The headers we made are getting more and more rust holes in them and trying to weld those closed just makes my original welding job on the headers worse. Welding thin tube headers with my welder and my skill set is just not a good match. There is a good chance the lack of performance improvements was due to my welding.

Anyway I decided there was no way I was going to spend the huge number of hours needed to build headers again for no noticeable performance increase. Also it would be nice to get on a standard off the shelf set of headers so I could just order a set if I crash (as opposed to spending a couple weeks of nights and weekends fabricating headers.)

I ending up ordering a set of Beyea Headers. The set I ordered was part number AMSST-23S1W which is an:

| Asphalt Modified Header - SST 23 degree 1 5/8 x 1 3/4 x 3" w/ Welded Collector |

I ordered these through Summit but it turns out they just forward the order to Beyea to fulfill and I would recommend just calling Beyea directly. It turned out that I had ordered the wrong part. The driver's side header didn't fit. The really nice people at Beyea responding immediately to my email with pictures showing the clearance problem with my clutch master cylinder. Turns out I really needed part number AMSST-23S1W CF. The CF apparently stands for "Cab Forward" and routes the tubes differently. I thought I still needed to work with them about how to return or do an exchange but before I even got to it the replacement header showed up at my door along with a prepaid UPS label to return the side I had that didn't fit. That was over and above in my book. I was the one who ordered the wrong part and I didn't even order it directly from them but they just wanted to get it fixed as quickly as possible and they paid shipping both ways for the exchange. I rather feel like I cheated them but I hope I can repay the favor by ordering more stuff from them in the future.

Here is the replacement. Plenty of room. The first one I bought couldn't even bolt up because it was hitting the clutch master cylinder.

Got to use my race car skills on the daily driver the other day. We ordered new wheels for the Bolt. We needed summer tires and it is just so nice to have separate wheels for summer vs winter tires that we decided to just order a new set of wheels with tires mounted from Tire Rack. They also had the Michelin Energy Saver A/S which is the OEM tire for the Bolt. The online Bolt forums pretty much agree these tires are good overall and do add significant range to the car. With an electric car more range is always good.

Anyway I ordered the wheels with TPMS sensors installed and added a relearn tool so I wouldn't have to go to a garage or deal with a TPMS warning for the rest of time. I was able to get the TPMS sensors to link up with three of the wheels but not the fourth. Tire Rack loses some points here. I followed the instructions they sent. I then called and was told that of course I should be doing something completely different. I tried that and when it didn't work I called again and was told that both of the first two methods (both from Tire Rack) are totally bogus and I should instead do this third procedure. So I tried that. The fourth wheel still would not respond and pair with the car. I of course called Tire Rack again. They tried to get me to try something else and this time I firmly told them that I've tried everything and the sensor on this one wheel is obviously dead and I am not interested in trying more things. I also blew up at them a bit for having multiple procedures that are not documented in the instructions they send. WTF every time I talked to someone they had a different idea and acted like I was an idiot for not having tried their magic combination of letting air out while standing on my head for 5 minutes or whatever.

Blowing up at them worked and the guy said they would send me a new TPMS sensor and credit my account $25 to get it installed. I'm pretty sure this would be sucky deal for most people. You would have to take your time to bring the wheel to a shop that could do the install and I'm not at all sure any shop would do the swap for $25. It's not a good deal for them. They made nothing on selling you the tires but Tire Rack wants them to clean up the mess for a small amount of money.

For me the $25 wasn't a bad deal. I've got plenty of experience mounting and dismounting tires from the race car. So I just got out the bead breaker and tire irons. Didn't even have to take the tire off to get enough clearance to swap in the new TPMS sensor and now all is well.

I left out the saga of the stripped wheel stud splines getting the left rear off the Bolt. I guess drilling out the stud and replacing it sort of qualifies as using race car skills. I'm not sure that in my previous life before I started wrenching on the race car that I would have been confident enough to believe I could drill out the lugnut and stud to get the wheel off and then replace the bad stud. But now it isn't that big a deal and the only part that was a pain was finding a parts store that had the wheel stud in stock.

Created a new nerf bar support today and fixed the center nerf bar support. Now I just need to finish creating the center neft support that was damaged at Ascutney.

Center nerf bar support tacked in place. Had to add on a new jacking point too. From here you can also see the rear bar which I bent back has a bit of a bow in it but it will do.

Haven't been doing much with no races in sight in spite of having more time on my hands. But working on getting things back together. Got the transmission back in with the new Howe clutch slave cylinder. The starter, distributor, plugs and some wiring done. The photo also shows the new vacuum gauge Sherm asked for since he thinks the engine dry sump is not pulling the vacuum it should.

Good Morning Sir I just subscribed so I can finally comment on posts instead of just being a stalker. I've been reading this page for almost a year to catch up, and I have learned a lot from you . As a mater of fact you're the reason I finally pulled the trigger and bought a 2 post lift Sir. I bought an Atlas PRO9D after following your posts on your Atlas lift. There's an Atlas dealer in Dallas TX. and he was very helpful getting me set up with what I needed. Thanks .

I'm from Maine but moved to Louisiana 12 years ago to make a living after shutting down my trucking company . I haven't seen any thing lately about your job situation ? I hope you are back to work soon . If I was still in Maine I would be looking for a chassis like yours and putting together a big cubic inch small block Ford motor with lots of low end grunt to put in it. I think my buddy Matt and I would have a lot of fun with that. Its like mud running used to be when we were doing it in the 90s, not priced out of the little guys range . More skill than cubic dollars.

I have a question about your breather line on the valve cover ? I'm guessing that's what it is ? What are you monitoring with the gauge ? Vacuum or pressure ?

I come home to Maine at least once a year its been hard to plan my trip this year because of this Zombie Apocalypse crap going on . But im hoping to make it up in September. I've been hoping you guys would have a hill climb event going on when im up .I'd love to see one .

Always looking forward to checking in to see if there's any new posts now that I've finally caught up to date.

Trigger99 said:

Good Morning Sir I just subscribed so I can finally comment on posts instead of just being a stalker. I've been reading this page for almost a year to catch up, and I have learned a lot from you . As a mater of fact you're the reason I finally pulled the trigger and bought a 2 post lift Sir. I bought an Atlas PRO9D after following your posts on your Atlas lift. There's an Atlas dealer in Dallas TX. and he was very helpful getting me set up with what I needed. Thanks .

Glad I can be any help. I love having the lift. Anyone who works on a car or cars regularly should have one. Of course most don't. The main reason seems to be that most people don't have a garage with a tall enough ceiling which is a shame. The lifts themselves are not that expensive. Not having to crawl around under the car is SO NICE!

I'm from Maine but moved to Louisiana 12 years ago to make a living after shutting down my trucking company . I haven't seen any thing lately about your job situation ? I hope you are back to work soon

Not a single bite on the job search. I've applied to lots of jobs but no luck. One problem is that I was working on a very old software package that had just recently been updated to be modern (Web based like everything is these days) but I personally had done almost none of the web side. Every job that is available these days wants years of experience building web apps. I can totally learn to do this but that doesn't get you a second glance.

If I was still in Maine I would be looking for a chassis like yours and putting together a big cubic inch small block Ford motor with lots of low end grunt to put in it. I think my buddy Matt and I would have a lot of fun with that. Its like mud running used to be when we were doing it in the 90s, not priced out of the little guys range . More skill than cubic dollars.

Yes hillclimbing is nice that way. Not too many competing with cubic dollars. They tend to go elsewhere, maybe because we don't give out big trophies. :-)

I have a question about your breather line on the valve cover ? I'm guessing that's what it is ? What are you monitoring with the gauge ? Vacuum or pressure ?

That line is the vent for the engine that goes back to the dry sump tank. The tank in turn is vented to atmosphere. The dry sump pump pulls out oil and air from the pan and should be pulling enough to draw a vaccum inside the engine. So the vent should actually be under vacuum and be pulling in some air from the dry sump tank. Based on some oil leakage I was having Sherm is wondering if there is some problem there. So we added a gauge on the return so I can check it when it is running.

I come home to Maine at least once a year its been hard to plan my trip this year because of this Zombie Apocalypse crap going on . But im hoping to make it up in September. I've been hoping you guys would have a hill climb event going on when im up .I'd love to see one .

Always looking forward to checking in to see if there's any new posts now that I've finally caught up to date.

You can check http://hillclimb.org for the schedule. The fall Ascutney event ( Sept 12-13) has not been canceled (yet anyway).

KG, good to see that you are trying to stay sane by engaging in time in the 'SHOP'.