I don't think I really documented my steering rack rebuild last time, so this time I made sure to take some pictures. I remember this process being really intimidating last time, but this time it went smoothly. There really aren't that many parts to deal with; you just need to make sure you remember where they go and take care not to damage any of the parts.

The seal kit arrived while I was at work today and I found some time after for the tear-down and cleaning. First comes the removal of the yoke support and the bottom pinion bearing cover (I made up the name, I don't know what the real term is). If you've been reading the past few posts you're more than familiar with the yoke support, but the bottom pinion bearing cover is a 24mm nut on the bottom of the rack. Look under it and you find:

The bottom pinion bearing; what else? Also though, you do find a 17mm nut that you definitely tightened before assembly but is now floating around loose on the threads. I distinctly recall torquing this to spec and now it's completely loose, so maybe some blue loctite is in order this time. Although it may be the fault of the bearing somehow, since this one is toast. Spinning it around has that distinct "crunchy" feelings that bearings get when it's time for them to go to the big toolbox in the sky.

The part number is Koyo 6001. I found a compatible part on Amazon with next-day delivery, 10 pack for $15. Generally I just prefer to buy Koyo / Timken the first time, but at that price I decided to just roll the dice. So much like those ball-bearings for the yoke support, if anyone needs a bottom pinion bearing, just let me know.

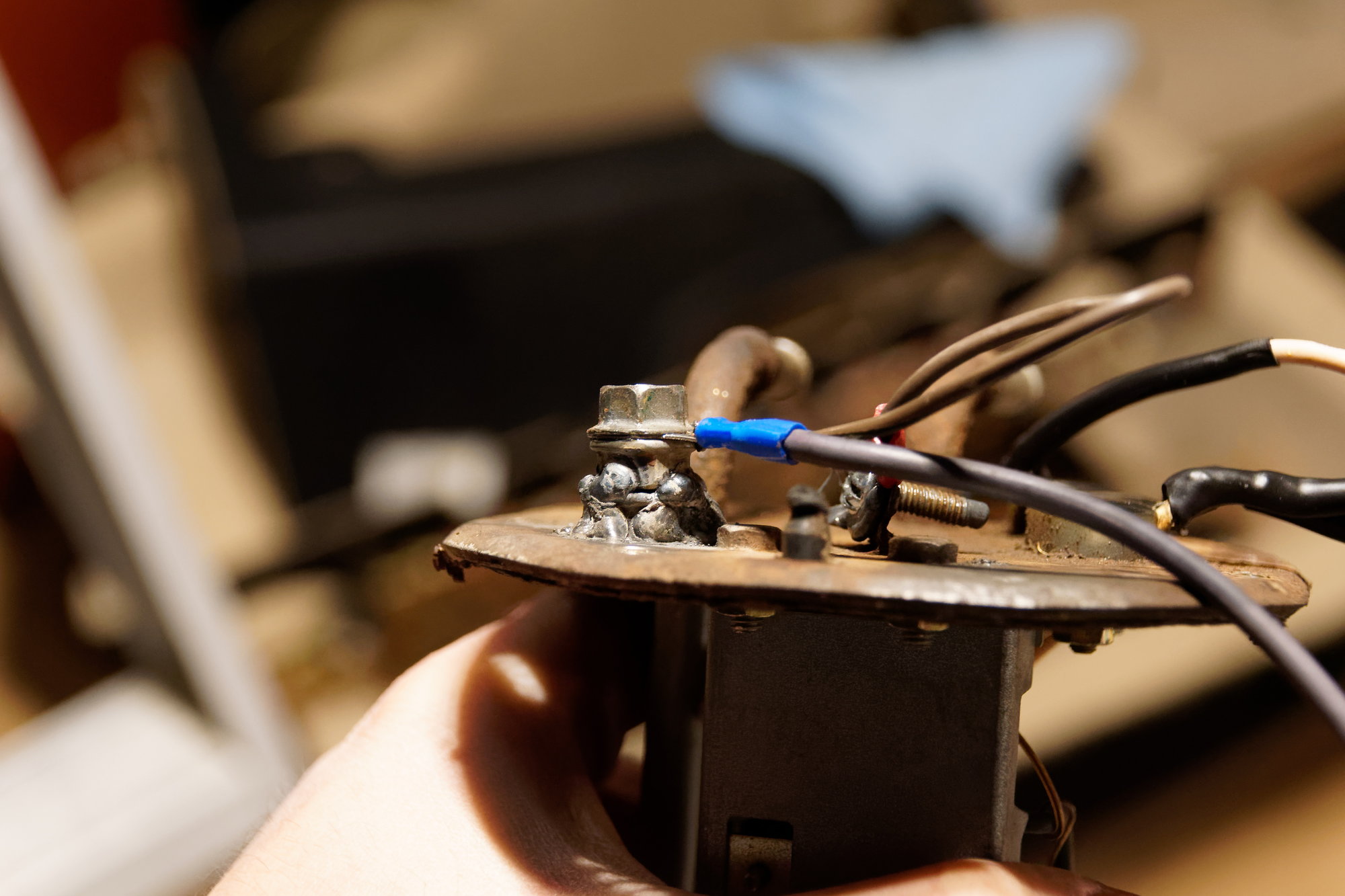

Next I took off a dust cover and snap-ring on top of the pinion. Then you can take the pinion assembly out by gently tapping on that bottom nut until it's loose in the housing, and removing the nut before pulling it all the way out:

The top bearing and bottom oil seal came out with it, which is normal. This part does the "magic" in a power steering rack. When you are turning left it pressurizes the one side of the piston and pushes the rack left, while allowing fluid out from the other side of the piston (through those hardlines). When turning right, it pressurizes and de-pressurizes the opposite sides and turns right. This way the pressurized ATF does the work for you, which is pretty nifty. Now that's my layman's understanding, and there are also some wacky things going on with the third line for the "reaction force" tube that I don't entirely understand. Basically it seems like that line senses how much pressure is opposing the turning motion of the tires (basically whether there is significant resistance like hot asphalt, or little resistance like snow) and does something with the valve in the pump to better react to road conditions. Again, layman's understanding.

Then I removed the hardlines from the back of the rack. They run from the pinion housing to the ATF side of the rack, and are what carries the actual pressurized fluid to press on the piston and move the rack. Next you need to remove the rack stopper:

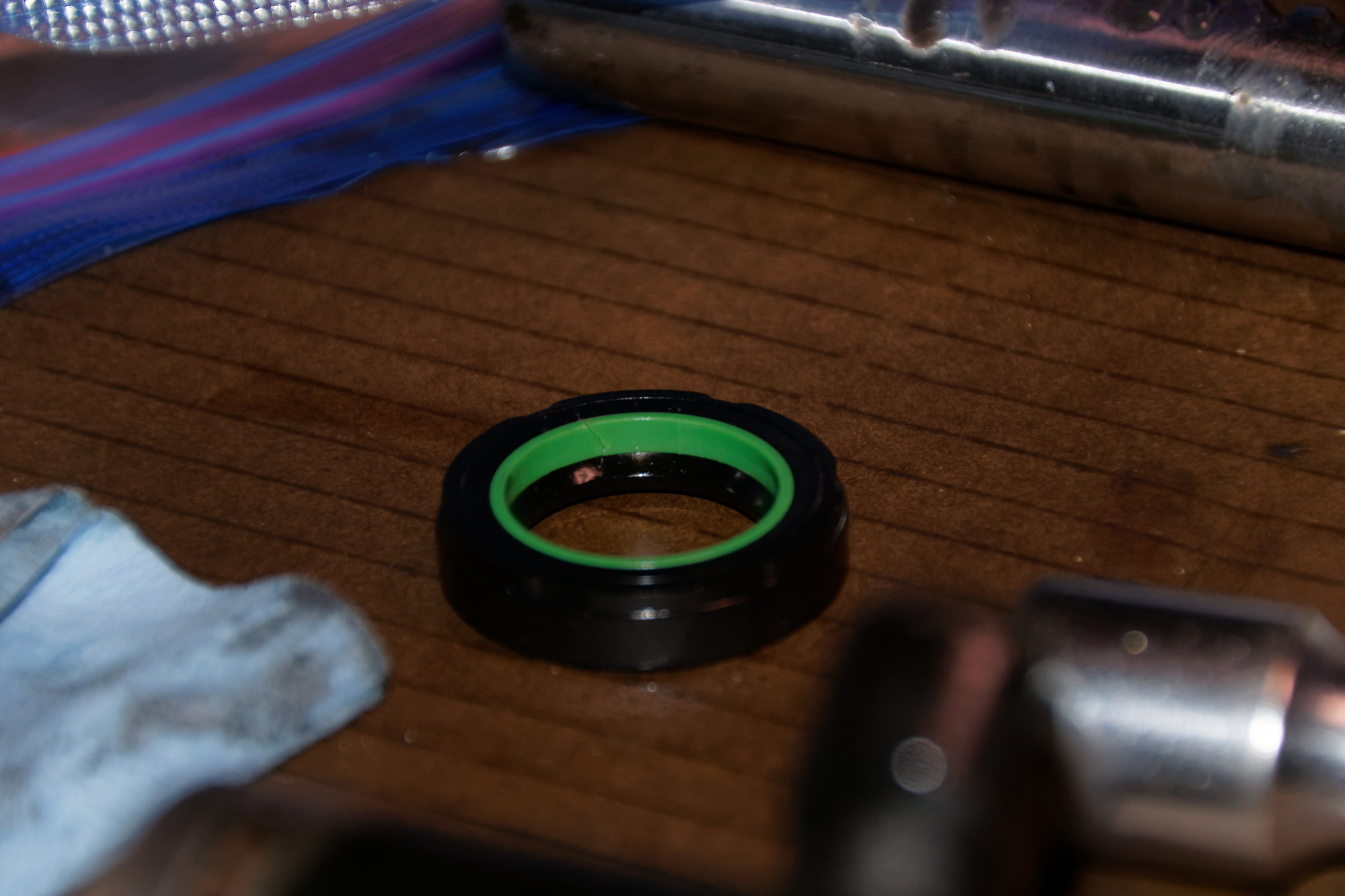

A screwdriver fits through those notches, then you rotate the little steel wire out of it's groove. Then the stopper pops out. After the stopper is removed, there is a fluid seal that sits inside a steel bushing, with an o-ring on the outside to seal against the tube. This is removed by gently tapping on the gear side of the rack with a dead-blow hammer and extension, basically using that piston on the rack itself to gently push the bushing and seals out. Then the rack is free:

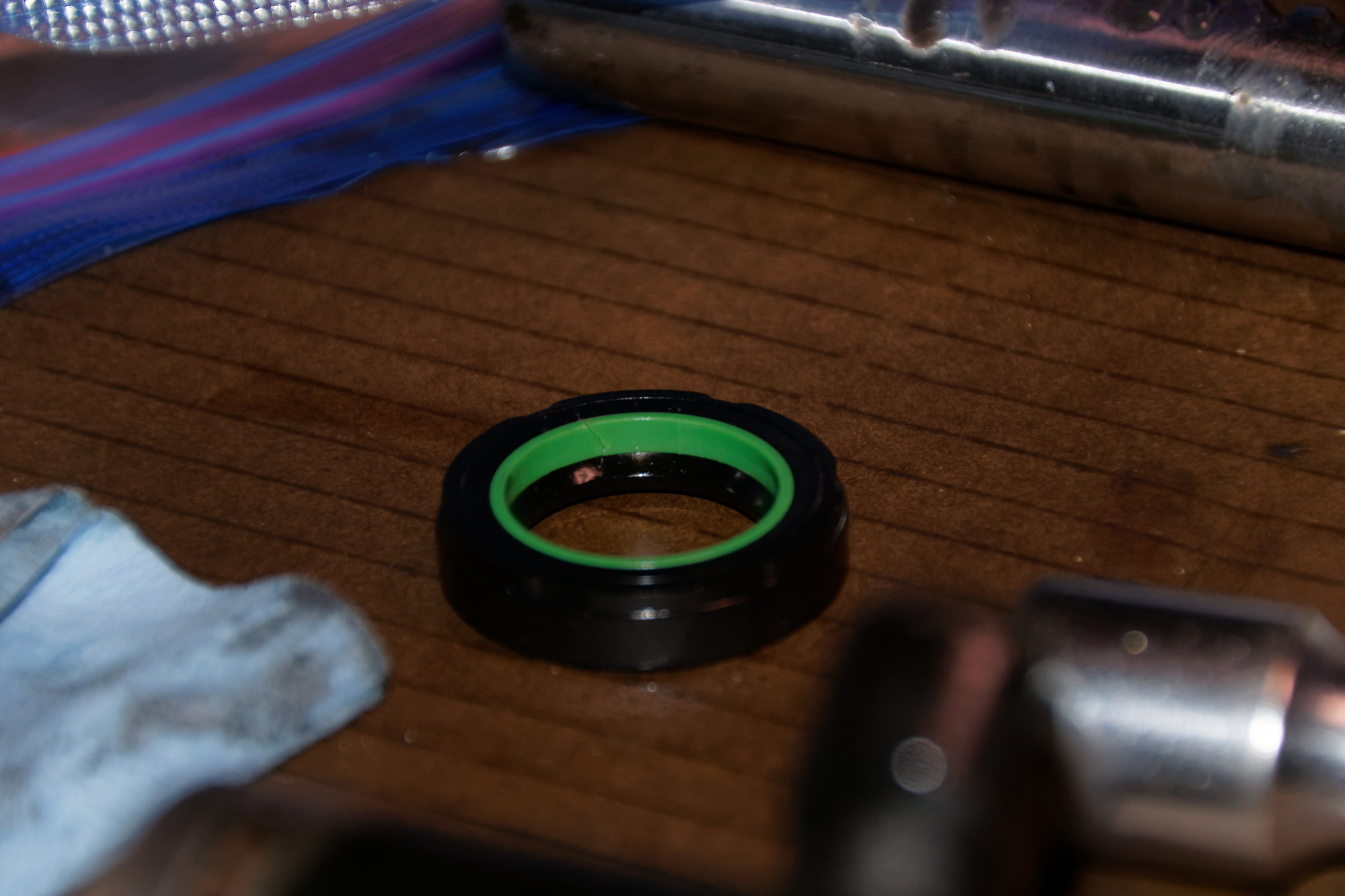

Then I used a 19mm socket and multiple extensions as a dead-blow hammer to remove the inner ATF seal and it's support piece:

This is the seal I mentioned before that is tough to install. It needs to slide over the toothed side of the rack, so it's easy to snag it and crack the plastic insert. I was 100% sure I got this right last time (practiced with the old seals a few times too), but it's clearly cracked. At least I have a likely culprit for the failure.

The last step is to remove the bottom pinion bearing. A socket and hammer (noticing a theme here?) made quick work of it. Note that a puller (blind-hole puller?) is the correct tool, but I don't have one. There is also a Mazda SST for the inner seal and support I mentioned above, but I don't have that either and the bearing & extensions work just fine as long as you take care with it.

After that it's time to clean everything very, very thoroughly and inspect for damage. The rack was exactly like I remember it last time; there is only one place with any visible wear:

The flash makes them look worse than they are, but they're barely visible to the eye. I'm wondering if the passenger's side tie-rod boot was compromised before I bought the car. There are no tears in it now, but it may have been replaced before.

I tried and couldn't feel anything that I could catch a nail on. With little else to go on (there is no procedure in the Factory Service Manual on what the acceptable wear is or how to measure), I'm using that as my barometer and calling it fine. Anything I do to try and improve it is liable to make it worse, so it's staying as it is.

This is the best picture I could get, but there is one more bearing we need to concern ourselves with:

Don't damage that needle bearing! Apparently Mazda doesn't acknowledge the part at all, it has no part number in the microfiche, and it's a non-standard side making it difficult to find a replacement. Let alone actually getting the old one out and the new one in. Thankfully mine is nice and smooth, so I don't have to worry about it.

Next I got the inside of the rack squeaky clean. Photographing this is a challenge, so this is the best I've got for you:

It's super smooth, so it looks like it's in good shape for the rebuild. Copious amounts of brake cleaner and a blue shop rag on a stick took care of the cleaning.

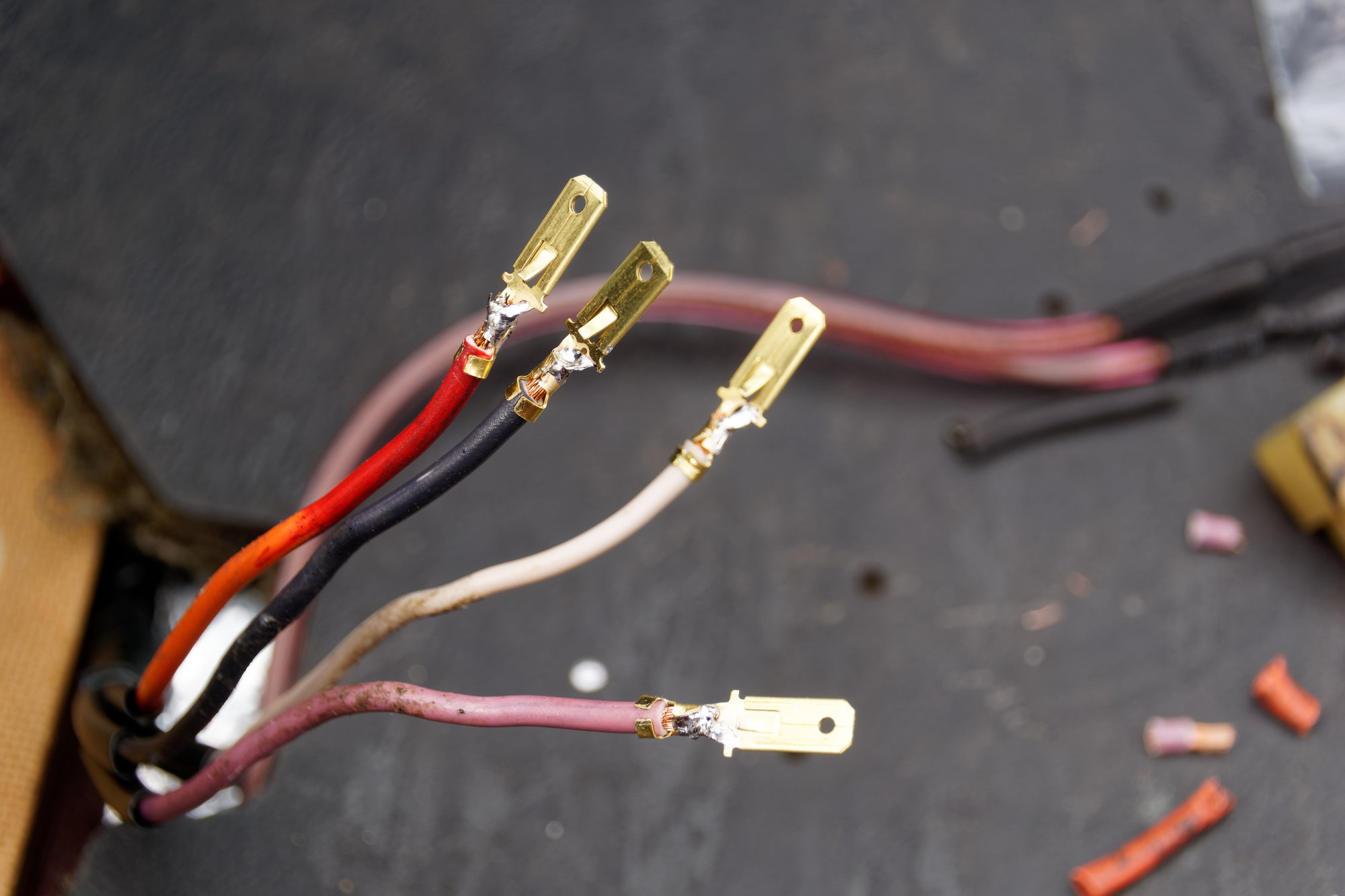

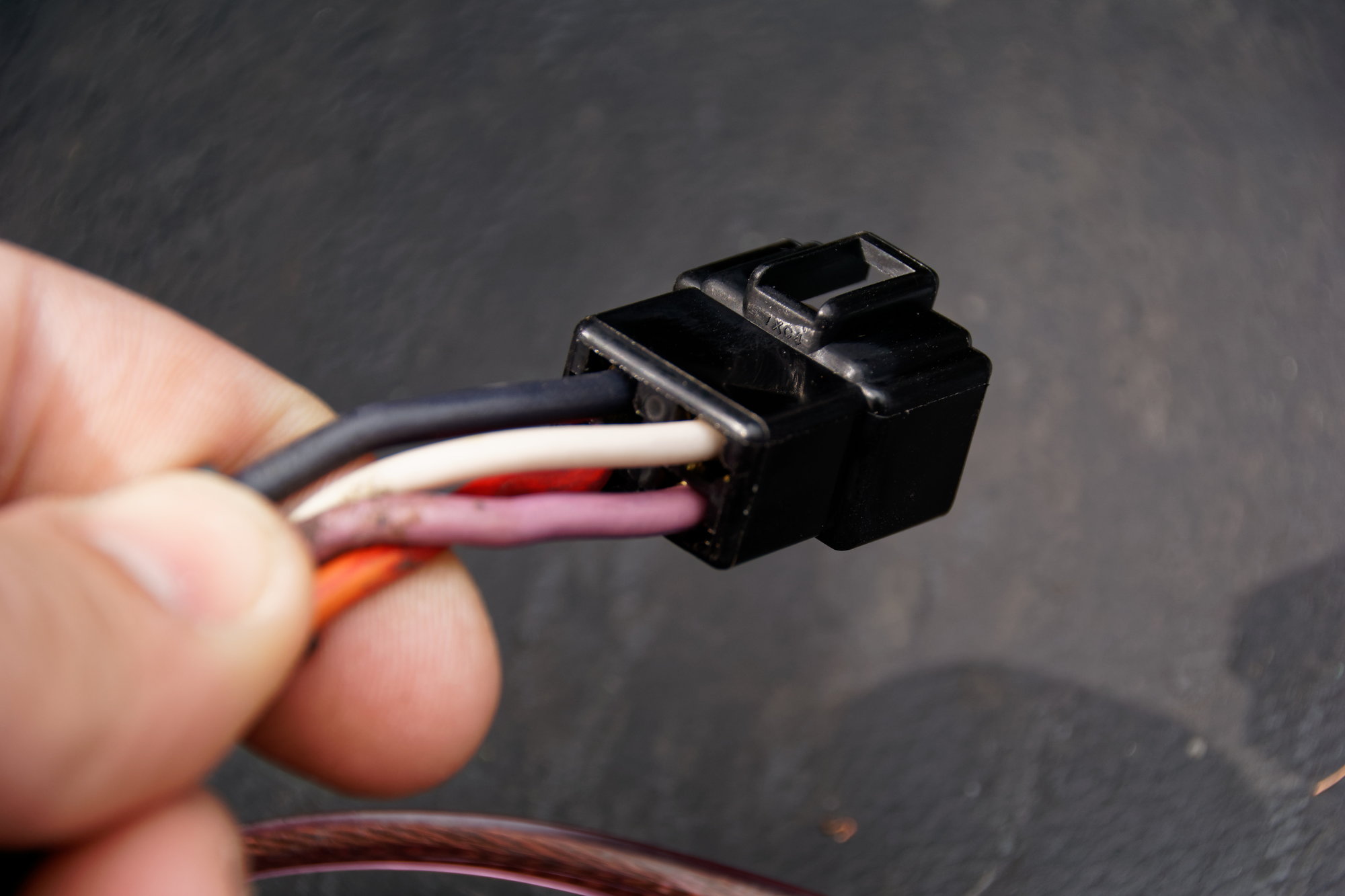

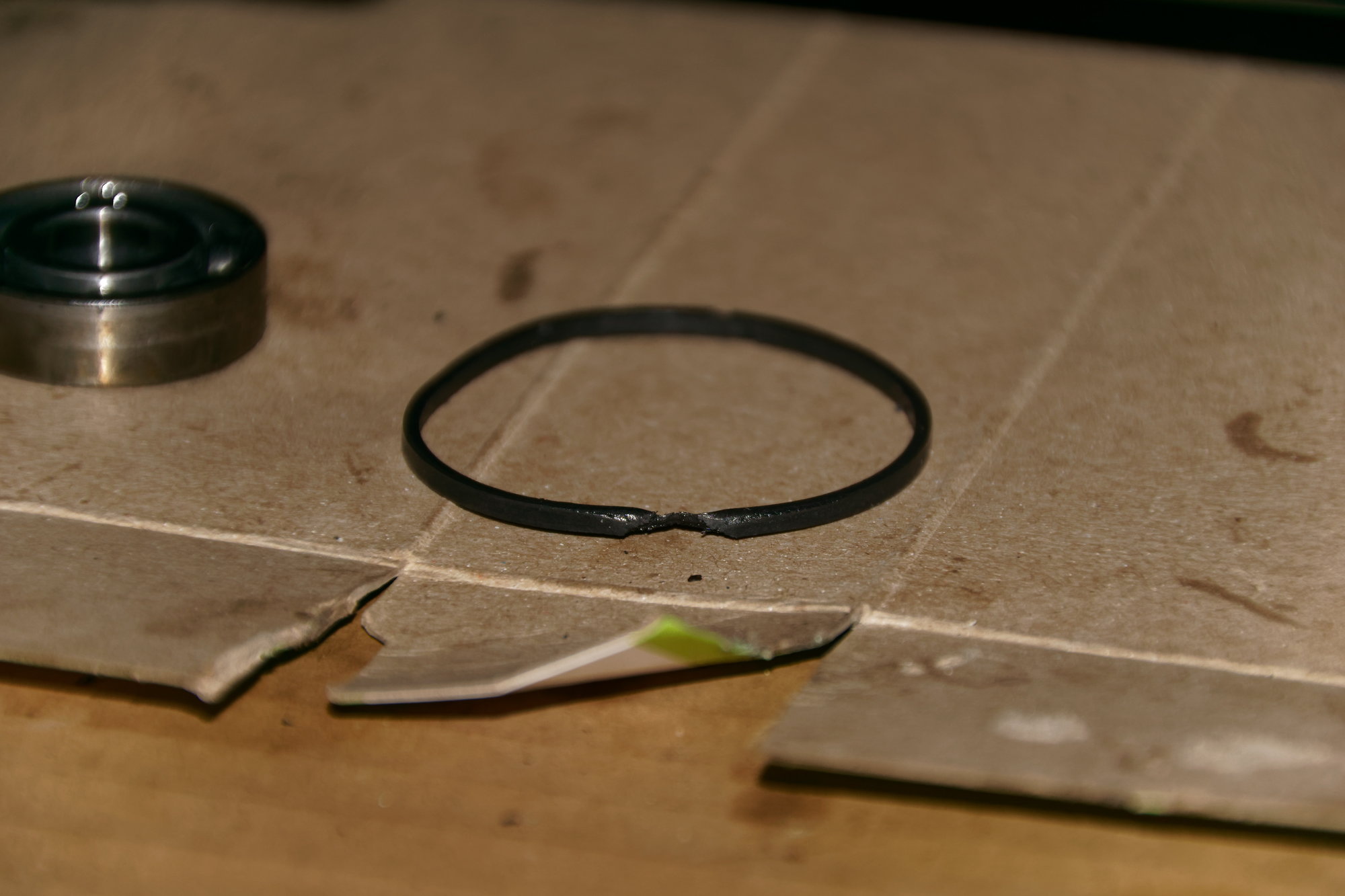

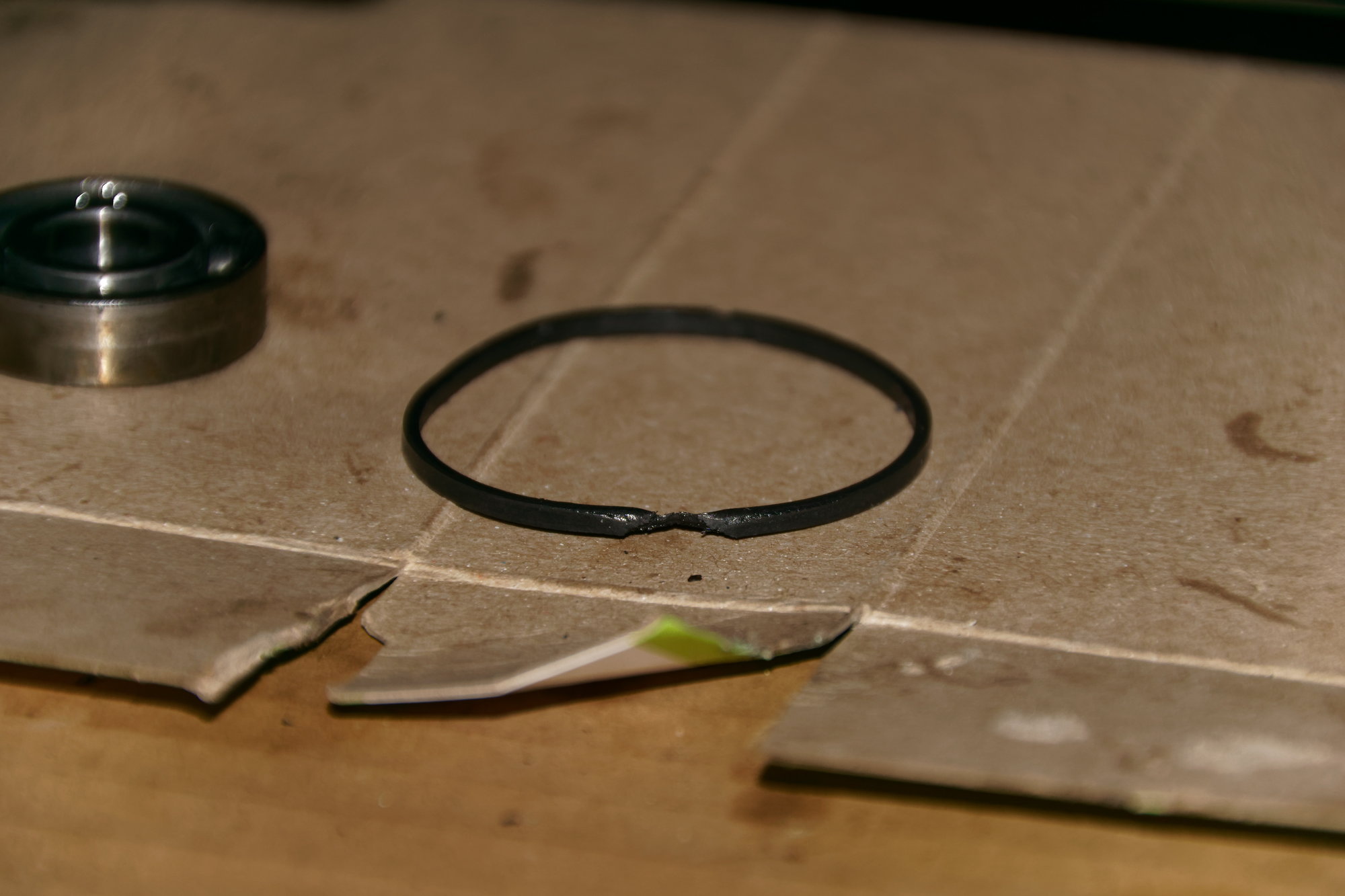

And the last part of note; one of the old seals on the pinion. There are four of these, and they are the least flexible seals I've ever seen. Take care not to break them when installing. This is one of the old ones I pulled out, and that is NOT the side I used the pick on to remove it. That was already there. And I definitely didn't assemble the rack with it damaged. I can only assume that either I snagged it on the install, or it was otherwise compromised and then the loose nut on the bottom of the pinion allowed it to wobble and wear down. The pinion, however, shows no signs of unusual wear or contact with the housing. To sum up: It's almost certainly something I did wrong, I just don't know exactly what.

Lastly, here's a photo of all the cleaned pieces. It took an hour at least, but they are all clean of grease now:

Please ignore my very messy workbench and the surrounding detritus. You can also see some marks on the back of the toothed portion of the rack. These are from driving around without that ball-bearing for awhile, but are just some light marks and won't affect operation of the rack and pinion. That part of the rack doesn't see ATF, only grease, and is only sealed by the dust-boot. After all that work cleaning, I immediately undid it by covering everything with a light coating of ATF. Rust never sleeps.

The bearing should arrive tomorrow, and I'm going to pick up some paint to make this look a lot nicer. I'm thinking I'll remove all the paint from the aluminum pinion housing and leave it bare, then get some satin black for the ATF side of the rack since it's steel. If all goes well the update should be soon and hopefully the rack is back in by Wednesday.

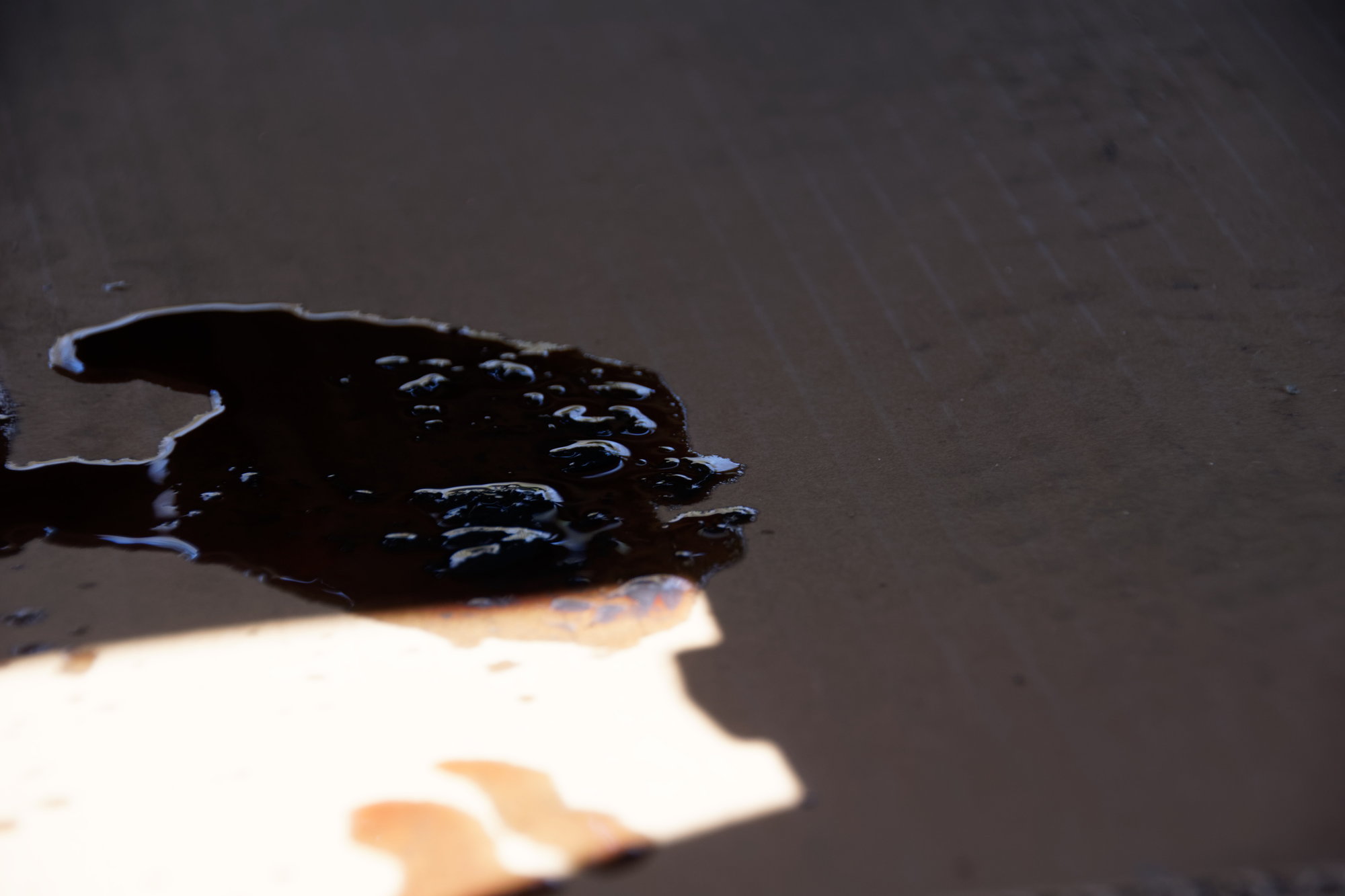

In other news, I was working on the brake lines near the master cylinder and when bleeding the brakes afterwards the rear left soft-line started to leak from the fitting. Not the fitting where it meets the hard-line, the actual crimped connection. Yikes. I've put in an order through Mazdatrix, and though my wallet hurts ($90 USD for the lines, $45 USD flat rate shipping to Canada, then exchange, and customs is inevitably going to rub salt in the wound), I know these lines are DOT approved and should last a long time. I don't remember where exactly I got the old braided stainless lines, but they clearly weren't good enough and I'm glad it failed in the driveway instead of on the road.

Until next time :)